Page 13 of 35

Reference: 708052-1

Issue date: 23-Jul-2014

Revision: B

1. Wire rope requires lubrication under normal conditions. Lightly lubricate it with a wire rope

lubricant specified by the wire rope manufacturer monthly or more often if necessary.

2. To prepare the end of IWRC wire rope for insertion, cut back the steel center at least 2”

(51mm) to allow for independent movement of the core. Braze and rough shape the end of

the wire rope to form a smooth, tapered, bullet shape no more than 1/4-in. (6.4 mm) long. DO

NOT cool the end of the hot wire rope in water or oil. This makes the end brittle and may

cause it to break off. Oil the bullet after it cools to prevent rusting.

3. Always uncoil and carefully examine the wire rope before use. Worn, kinked, bird-caged, or

damaged wire rope cannot be repaired. It must be replaced.

4. Use a heavy-duty thimble for the main suspension wire rope and follow the manufacturer’s

requirements for termination of the wire rope hardware that you are using.

5. Be sure there is enough wire rope to reach the lowest possible point of travel.

6. Wire rope begins to wear the moment it is used. It must be regularly inspected to be sure it

is in good condition. Wire rope must be removed from service when diameter loss or wire

breakage occurs as listed within CAN/CSA - Z271 (See following page)

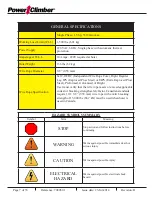

WARNING

Wire rope stretches when loaded. The diameter is reduced. Always inspect the

wire rope termination and refer to the manufacturer’s inspection procedures.

ALL DIMENSIONS ARE INCHES.

( )

( )