Prepare for work

1. Check and replace any damaged or worn

parts on the tool.

2. Place a few drops of pneumatic air tool oil

into the air inlet. If you use an automatic

inline oiler, check and add oil if necessary.

3. Make sure the magazine is empty of all

fasteners and the hose has an adequatley

rated work pressure, then connect the tool

to the air compressor.

4. Keep the tool pointed away from you and

others at all times. Do not load fasteners

with the trigger or safety depressed.

5. Regulate the air pressure to obtain 80 to 110

PSI, depending on working demands and

the workpiece.

6. Before loading the fasteners, disconnect the

tool from the air supply. Gripping the tool

firmly, pull the pusher back and engage the

latch.

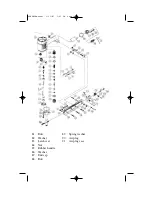

7. Insert a strip of fasteners, keeping the point down (see fig 1.)

8. Orient and slide the strip of fasteners forward to the front of the magazine.

9. Release the latch and pusher, slide the pusher against the nails (see figure

2.)

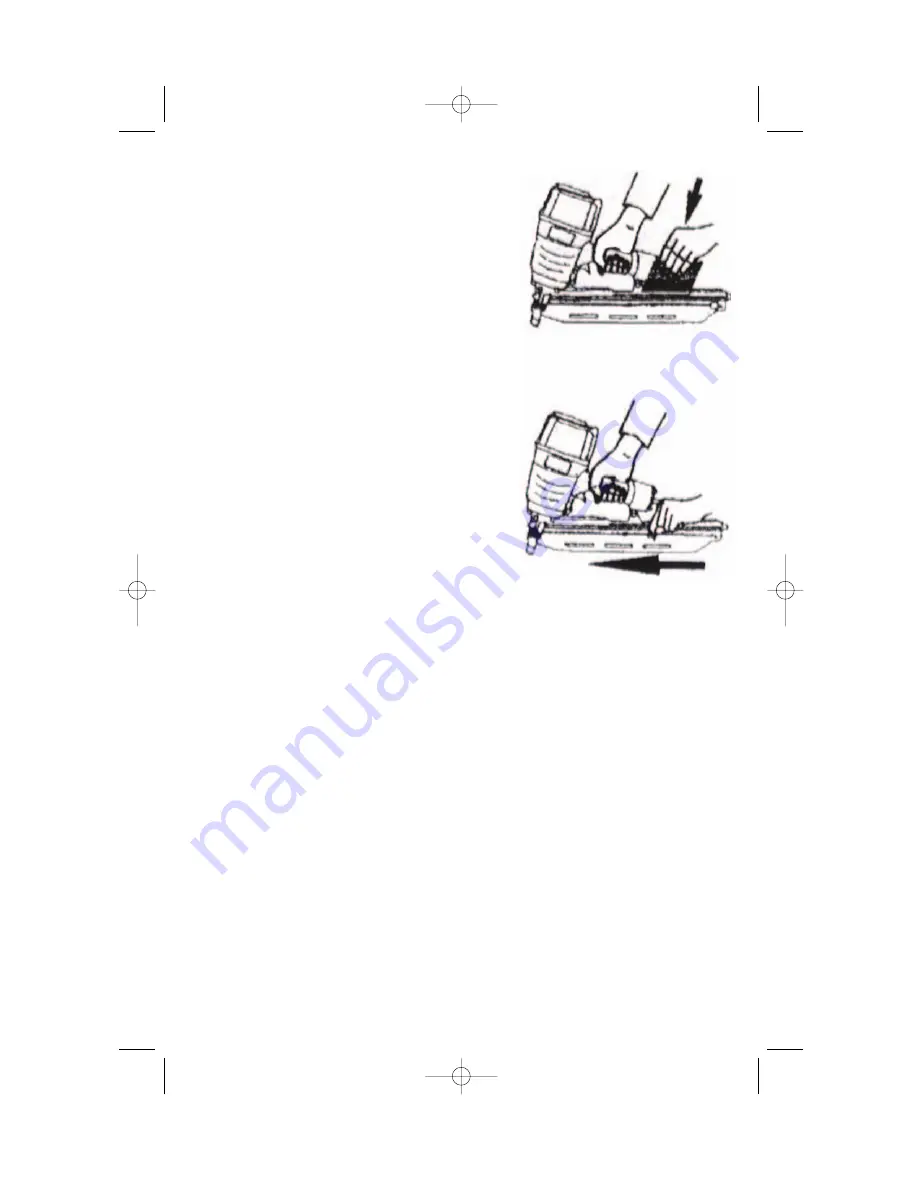

Using the Tool

Wearing approved safety glasses and protection equipment to protect eyes

and ears, grip tool firmly, pointing the drive to the workpiece. Depress

nosepiece onto work surface, then squeeze trigger to fire a fastener. The

amount of air pressure required will vary, depending on the size of the

fastener and the material being fastened.

Excessive air pressure can cause premature wear and damage to the tool. Test

the driving depth in a sample piece of wood before use. If the fasteners are

being driven too far or not far enough, adjust the regulator to provide less or

more air pressure as required.

1

2

8006020manual 1/31/07 3:23 PM Page 5