tOOl USE AND cARE

1. Use the right tool for the job.

Do not attempt to force a small tool or attachment to do the work of a

larger industrial tool. The tool will perform better and safer at the task for which it was intended. Do not

modify this tool or use for a purpose for which it was not designed.

2. Maintain tools with care.

Keep tools clean, sharp and in good condition for a better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool fittings,

alignment and hoses periodically and, if damaged, have them repaired by an authorized technician

or replaced. The handles must be kept clean, dry and free from oil and grease at all times. A properly

maintained tool reduces the risk of binding and is easier to control. Sharp tools are safer than tools which

have become dull because you do not have to apply excessive amounts of force to make your cuts.

Applying excessive force can lead to slips and damage to your work or personal injury.

3. Remove adjusting keys and wrenches.

Check that keys and adjusting wrenches are removed from the

tool or machine before connecting it. A wrench or key that is left attached to a rotating part of the tool

increases the risk of personal injury.

4. Avoid unintentional starts.

Be sure that the throttle is in the OFF position when not in use and before

connecting it to any air source. Do not carry the tool with fingers near or on the switch.

5. Only use the lubricants supplied with the tool or specified by the manufacturer.

Other lubricants

may not be suitable and may damage the tool or even make the tool explode.

6. When not in use for an extended period, apply a thin coat of lubricant to the steel parts to avoid

rust.

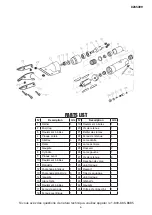

SERvIcE

1. check for damaged parts.

Before using any tool, any part that appears to be damaged should be

carefully checked to determine that it will operate properly and perform its intended functions. Check

for alignment and binding of moving parts; broken parts or mounting fixtures, or any other condition

that may affect proper operation. Any part that is damaged should be properly repaired or replaced by a

qualified technician.

2. When servicing, use only identical replacement parts.

Only use accessories intended for use with this

tool.

ElEctRIcAl SAfEty

1. Protect yourself against electric shocks when working on electrical equipment. this tool is not

insulated.

Prevent body contact with grounded surfaces such as pipes, radiators, cooking stoves and

refrigerators. There is an increased chance of electrical shock if your body is grounded.

AIR SOURcE

1. Disconnect air supply.

Disconnect from air pressure source when not in use, before cleaning, servicing

or changing a piece or accessory. After disconnecting, discharge any residual air pressure from the tool.

2. Do not use the tool if the trigger switch does not function properly.

Any tool that cannot be

controlled with the ON/OFF switch is dangerous and must be repaired.

3. Use proper size and type of air pressure line and fittings.

The recommended air line for this tool is

1/4" NPT air inlet. Do not connect this tool to an air source capable of exceeding 90 PSI.

4. Always verify prior to using the tool that the air source has been adjusted to the rated air pressure

or within the rated air-pressure range.

Over pressurizing the tool may cause bursting, abnormal

operation, breakage of the tool or serious injury to persons. Use only clean, dry regulated compressed air

at the rated range as marked on the tool.

5. Never use pure oxygen, carbon dioxide, combustible gases or any bottled gas as an air source for

the tool.

Such gases are capable of causing an explosion and serious injury to persons. Do not use an

air source besides an air compressor to power this tool.

6. Always use an air regulator and a moisture trap in your compressed air system.

7. Avoid using an unnecessarily long air hoses.

Choose a hose that is appropriate for the situation, as a

hose that is too long and running across the floor can be more dangerous than helpful.

8. Always carry this tool by it's handle, never carry the tool by the air hose.

vIbRAtION PREcAUtIONS

This tool vibrates during use. Repeated or long-term exposure to vibration may cause temporary or permanent

physical injury, particularly to the hands, arms and shoulders. To reduce the risk of vibration-related injury:

1. Anyone using vibrating tools regularly or for an extended period should first be examined by a

doctor and then have regular medical check ups to ensure medical problems are not being caused

by or worsened from tool use.

Pregnant women or people who have impaired blood circulation to the

hands, past hand injuries, nervous system disorders, diabetes or Raynaud's Disease should not use this

for any technical questions, please call 1-800-665-8685

2

8265399