USer-maintenance inStrUctionS

Only a qualified technician must perform procedures not

specifically explained in this manual.

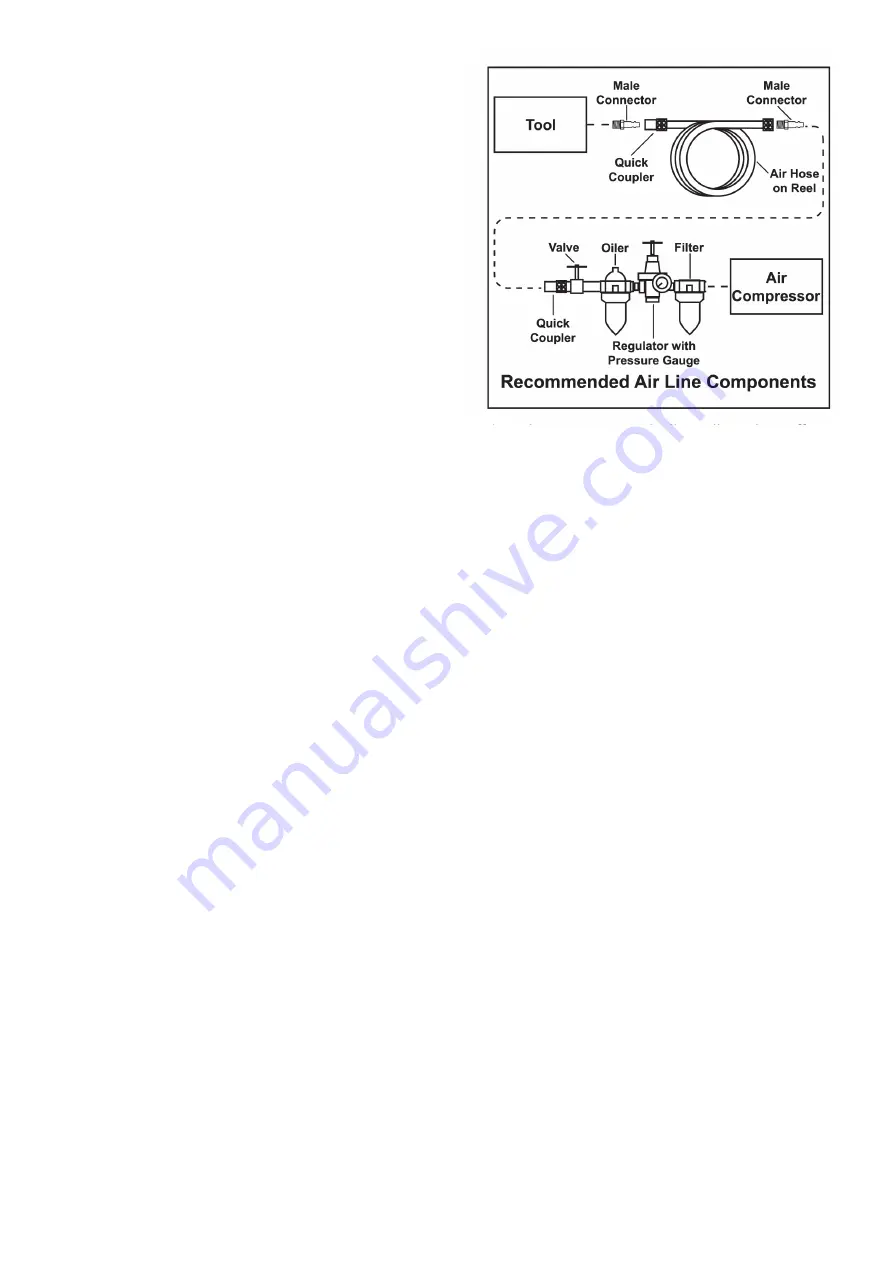

Incorporate an in-line oiler, shut-off valve,

regulator with pressure gauge, and filter for

best service, as shown in the diagram.

An

in-line shutoff valve is an important safety device

because it controls the air supply even if the air

hose is ruptured.

Note:

If an automatic oiler system is not used, add

a few drops of pneumatic tool oil to the airline

connection before operation. Add a few more

drops after each hour of continual use.

tO PREvENt SERIOUS INjURy fROM

AccIDENtAl OPERAtION

Turn off the tool, detach the air supply, safely discharge any

residual air pressure in the tool, and release

the throttle and/or turn the switch to it’s OFF position before

maintenance or cleaning procedures.

tO PREvENt SERIOUS INjURy fROM tOOl fAIlURE

Do not use damaged equipment.

If abnormal noise, vibrations or leaking air occurs, have the problem

corrected before further use.

tO PREvENt ExPlOSION

lubricate the tool only with specified lubricants.

Lubricate the air inlet using only pneumatic tool oil. Lubricate the

internal mechanism using only white lithium grease. Other lubricants may damage the mechanism and may be highly

flammable, causing an explosion.

cleaning, maintenance, and lUbrication

Note:

The procedures are in addition to the regular checks and maintenance explained as part of the regular

operation of the air-operated tool.

DAIly AIR SUPPly MAINtENANcE

Every day, perform maintenance on the air supply according to the component manufacturers’ instructions.

The lubricator’s oil level needs to be maintained and the moisture filter must be regularly drained. Performing routine

maintenance on the air supply will allow the tool to operate safer and will also reduce wear on the tool.

Note:

Always follow all manufacturer’s safety warnings and procedures for the air compressor and components you

are using with this tool.

QUARtERly (EvERy 3 MONthS)

have the internal mechanism cleaned, inspected, and lubricated by a qualified technician.

If the vanes need

replacement, all vanes should be replaced as a set.

AS NEEDED

When tool performance decreases, it may be caused by dulling of the blades.

When the blades become dull,

they need to be changed. Use the included hex wrench to remove the lock screws (27) on the cutter housing (21).

Remove the blades and bushings and replace with new blades in the same orientation as those removed. Replace all

blades at the same time. Secure the cutter housing before use.

for any technical questions, please call 1-800-665-8685

4

8265399