V4.1

4-1/2 in. Metal Cutting Band Saw

8699159

Visit www.princessauto.com for more information

19

ADJUST THE STOCK STOP

1. Loosen the Socket Head Screw (#17) that holds

the Stock Stop (#18) to the Shaft (#19).

2. Adjust the Stock Stop to the desired length

position. Retighten the Socket Head Screw.

ADJUST THE BLADE GUIDE BEARINGS

A crooked cut may be the result of misaligned blade guides or uneven wear on

the Saw Blade (#66). Install and test a new saw blade to eliminate a dull blade

as the cause of the problem, before adjusting the Blade Guide Bearings (#72).

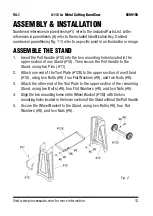

1. Check that the Blade Guide Bracket Seats

(#67, 74) are clear of the Saw Blade. There

should be from 0.000 in. (just touching) to

0.001 in. clearance between the Saw Blade

and Blade Guide Bearings (Fig. 18).

2. Adjust the Outer Blade Guide Bearings

(Fig. 18-1) that are mounted to the Eccentric

Shafts (#76) by loosening the nuts (#5) while

holding the Blade Guide Bearings.

3. Turn the Outer Blade Guide Bearings

gradually until they are clear of the Blade.

Then retighten the Nuts.

4. Adjust the Inner

Blade Guide Bearings (Fig. 18-2) by loosening the Bolts

(#70) holding the Blade Guide Brackets (#73, 79) in place. Move the Blade

Guide Brackets forward or back until the proper clearance is obtained.

Retighten the Bolts.

ADJUST THE BLADE TRACKING

DANGER! When the tool is in operation, keep hands away from the saw blade

and the area it is being applied to. Failure to follow this warning will result

in amputation, serious personal injury or death.

IMPORTANT! The Blade Guide Bearings should be completely clear of the

Saw Blade if adjustment is necessary (see Adjust the Blade Guide Bearings).

This procedure requires running the Band Saw with the Blade Back Cover open.

Fig. 17

Fig. 18

18-1

18-2