8976052

MINIMIG 100E Flux-Cored Welder

V4.0

26

For technical questions call 1-800-665-8685

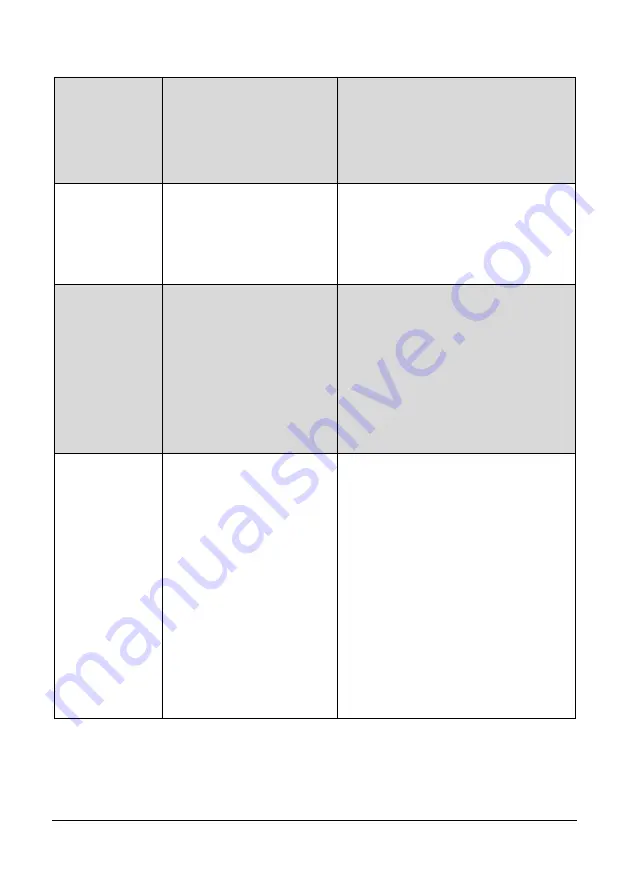

Arc works but

not feeding

wire.

1. No tension on drive

roller.

2. Faulty wire speed

control assembly.

3. Faulty drive motor.

1. Adjust the drive tension.

2. Replace wire speed control

assembly.

3. Replace drive motor.

Nothing works

except fan.

1. Exceeded duty cycle;

thermal protector

opened.

2. Faulty trigger on torch.

3. Faulty transformer.

1. Let welding unit cool at least 15

minutes (observe and maintain

proper duty cycle).

2. Replace torch trigger.

3. Replace transformer.

Welding unit

overheats -

blows fuses,

trips circuit

breaker.

1. Use of extension cord.

2. Electrode diameter too

large.

3. Overloaded circuit.

1. If possible, relocate welding unit to

avoid use of extension cord. If

relocation is not possible, use

thicker (low gauge number)

extension cord.

2. Use smaller diameter electrode.

3. Welding unit requires a dedicated

circuit. Remove all other electric

devices on the circuit.

Low output or

non-

penetrating

weld.

1. Loose connection

inside machine

2. Too long or improper

extension cord.

3. Wrong type or size

wire.

4. Poor ground

connection.

5. Wrong size contact tip.

6. Loose torch connection

or faulty torch

assembly.

7. Dirty or rusty welding

wire

1. Blow inside of machine out with

compressed air. Clean and tighten

all connections.

2. Extension cords are discouraged.

Move welding unit close to power

source.

3. Use correct size wire.

4. Reposition clamp and check cable

to clamp connection.

5. Use correct size contact tip.

6. Tighten torch or replace torch.

7. Replace spool of welding wire.