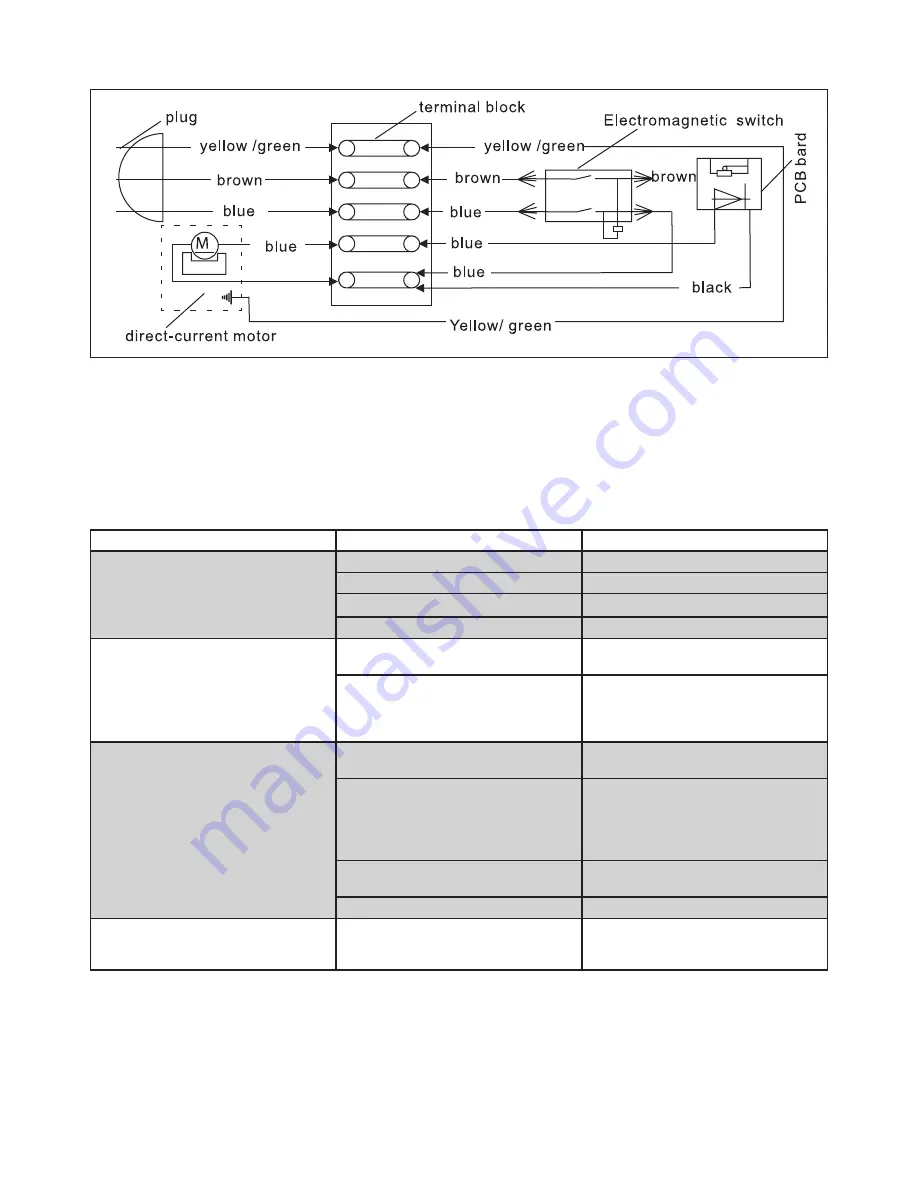

WIRING DIAGRAM

TROUBLESHOOTING

WARNING: FOR YOUR OWN SAFETY, ALWAYS PUSH THE OFF SWITCH "O" AND UNPLUG

THE POWER CORD FROM THE ELECTRICAL OUTLET BEFORE TROUBLESHOOTING

YOUR SCROLL SAW.

PROBLEM

PROBABLE CAUSE

REMEDY SUGGESTED

Breaking blades

1. Wrong tension

1. Adjust blade tension

2. Over working blade

2. Reduce feed rate

3. Wrong-blade application

3. Use narrow blades for cutting

4. Twisting blade in wood

4. Avoid side pressure on blade

Motor will not run

1. Defective cord or plug

1. Replace defective parts before using

saw again

2. Defective motor

2. Consult the Customer Service Center.

Any attempt to repair the motor may

create a HAZARD. Repairs must be

done by a qualified service technician

Vibration

NOTE: There will always be some

vibration present when the saw is

running because of the motor

operation.

1. Improper mounting of saw

1. See mounting instructions in this

manual for proper mounting technique

2. Unsuitable mounting surface

2. The heavier your work bench is the

less vibration will occur. Plywood

workbench will not be as good a work

surface of solid lumber. Use common

sense in choosing a mounting surface

3. Loose table or table resting against

motor

3.Tighten table lock knob

4. Loose motor mounting

4.Tighten motor mounting screws

Blade Runout -

Blade not in-line with arm motion

Blade holders not aligned

Loosen cap screws holding blade

holders to arms. Adjust position of blade

holders. Retighten holders.

For any technical questions, please call 1-800-665-8685

11

8159642