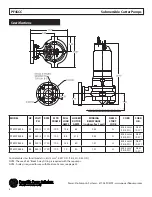

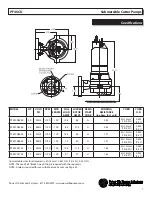

18

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

Maintenance

No lubrication or maintenance is required.

Perform the following checks when pump

is removed from operation or when pump

performance deteriorates:

a). Inspect seal chamber for oil level

and contamination.

b). Inspect impeller, adjust cutter knife

and blade.

c). Inspect motor and bearings.

d). Inspect lower seal for wear or leakage.

Servicing

NOTE: Item numbers in ( ) refer to Figures

6 & 7.

Seal Chamber Oil -

Anytime the pump

is removed from operation, the oil in the

seal chamber should be checked visually

for oil level and contamination.

To check oil, set unit on its side with pipe

plug (23) downward, remove pipe plug

(23) and drain oil from seal chamber.

Make sure it is clean and clear, light

amber in color and free from suspended

particles. Milky white oil indicates the

presence of water and lower seal should

be inspected or replaced.

Oil Testing

• Check oil for contamination using an

oil tester with a range to 30 Kilovolts

breakdown.

• If oil is found to be clean and

uncontaminated (measuring above

15 KV. breakdown), refill seal chamber.

• If oil is found to be dirty or

contaminated (or measures below

15 KV. breakdown), the pump must

be carefully inspected for leaks.

After leak is repaired, dispose of old oil

properly, and refill with new oil.

Oil Replacement:

Seal Chamber -

Drain all oil (if not already

done so) from seal chamber and dispose

of properly per Local and Environmental

Standards. Refill with approx. 51 oz. with

new oil, see chart.

Cooling Oil

Recommended Supplier/Grade

BP

Enerpar SE100

Conoco

Pale Paraffin 22

Mobile

D.T.E. Oil Light

Shell Canada

Transformer-10

Texaco

Diala-Oil-AX

Before any service

work is done,

disconnect and lock out

electrical power to pump.

Disassembly

Cutter & Impeller -

Remove cap screws

(45) and washer (47) from volute (40). Lift

motor from volute (40). Clean out volute

and check impeller for pitting or wear. To

replace impeller (41), remove plug (50),

screw (48) and washer (49). Pull impeller

straight off shaft with a wheel puller.

Carefully remove impeller (41) so as not to

damage the lower seal.

NOTE:

Seal spring

relaxes when impeller is removed and may

cause oil to leak through.

Impeller and knife

assemblies are

EXTREMELY SHARP

!

Handle with care.

To install impeller, check that lower seal is

in place, apply a thin film of oil to motor

shaft and slide impeller straight onto

shaft. Apply thread locking compound to

screw (45), and with washwe (11) place

into shaft and tighten. Check impeller for

binding. Assemble volute (40) onto motor

assembly with screws (45) and washers

(47). Apply thread locking compound on

screws (45).

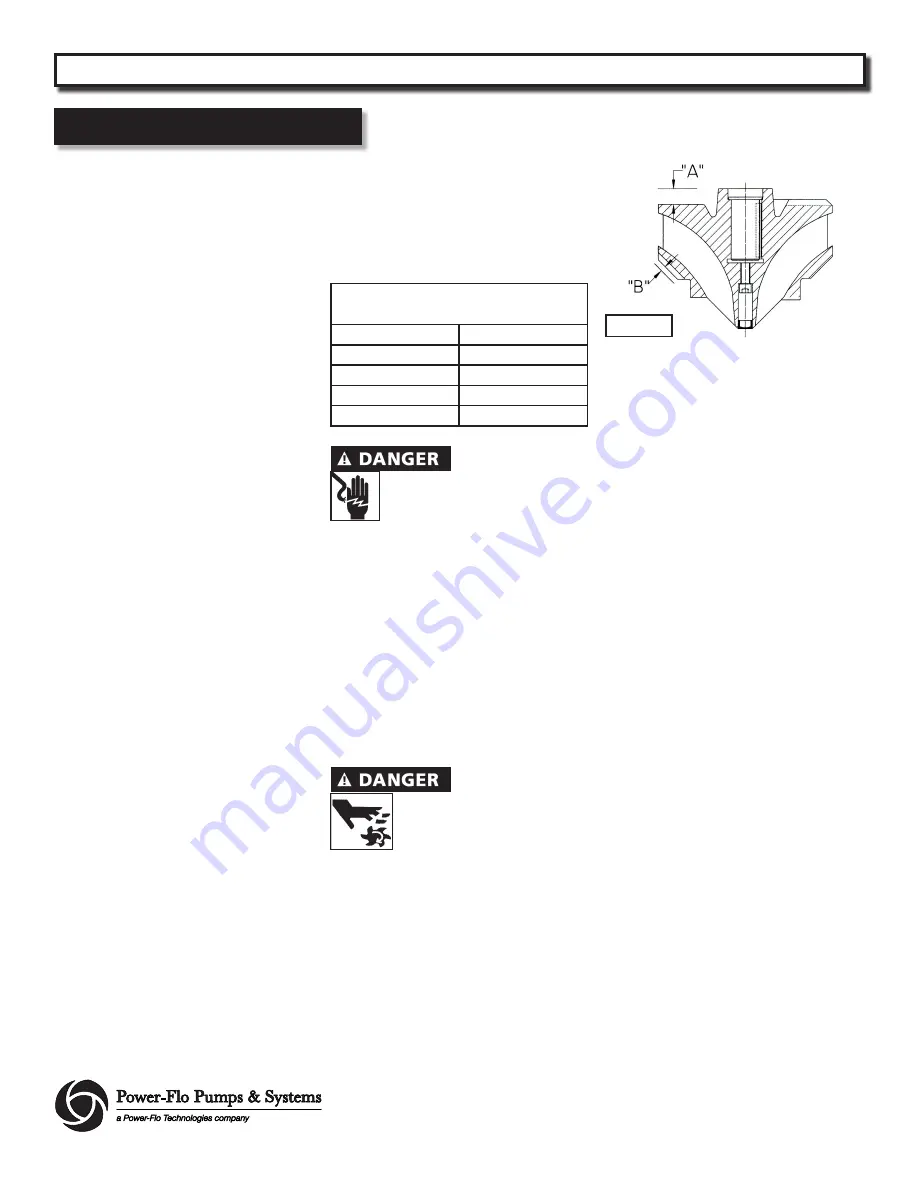

Check the gap (A) between the intermediate

and upper portion of impeller with a feeler

gauge which should be between .012” -

.059”. Gap (B) between the lower portion

of impeller and volute should be between

.012” - .059”. See Figure 3.

Cutter Height Adjustment -

Loosen two

screws (51) and bring the upper surface of

the blade as close as possible to the lower

heel of the impeller without touching and

tighten firmly.

Cutter Angle Adjustment

- Loosen two

screws (45) and move the knife (42) across

so as to bring blade flush up to the point

of the impeller, permitted play between

.002” - .005” and tighten firmly.

Cable Assembly -

Loosen cable

connectors (32) and (35), replace if

required. Remove cap screws (19),

washers (20) and cable box cover (5) from

motor housing (1). Remove cable lead

wires from motor lead wires and sensor

wires from control cable by unscrewing

connectors (31) and (32). Note wiring

connections for reassembly. Remove

screw (26), washer (27) and ground wire

(30) from cover plate (5).

Service

PF4SCC, 4SCD, 4SCE, 4SCF

Submersible Cutter Pumps

Figure 3