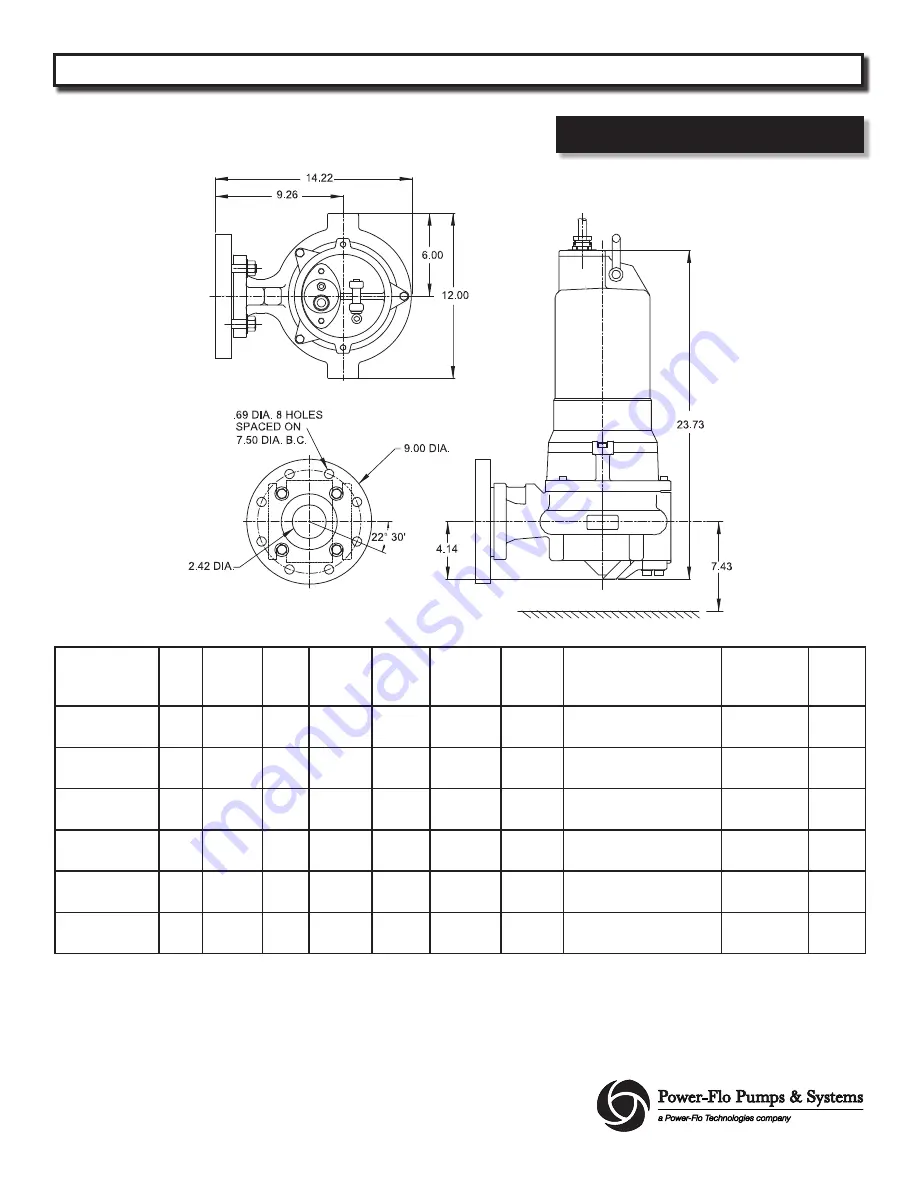

7

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

MODEL

HP

VOLT/

PH

RPM

MTR

FRAME

FULL

LOAD

AMPS

LOCKED

ROTOR

AMPS

NEMA

START

CODE

WINDING

RESISTANCE

(in ohms, for 1 coil)

CORD

CORD

O.D.

PF4SCD4236

4.2

230/3

1150

100

12.8

63

G

2.45

4G1.5mm

2

(14/4, SO)

0.453

(0.57)

PF4SCD4246

4.2

460/3

1150

100

6.4

31.5

G

2.45

4G1.5mm

2

(14/4, SO)

0.453

(0.57)

PF4SCD4834

4.8

230/3

1750

100

14.4

80

H

1.21

4G1.5mm

2

(14/4, SO)

0.453

(0.57)

PF4SCD4844

4.8

460/3

1750

100

7.2

40

H

1.21

4G1.5mm

2

(14/4, SO)

0.453

(0.57)

PF4SCD7134

7.1

230/3

1750

100

19.4

114

H

1.65

4G1.5mm

2

(14/4, SO)

0.453

(0.57)

PF4SCD7144

7.1

460/3

1750

100

9.7

57

H

1.65

4G1.5mm

2

(14/4, SO)

0.453

(0.57)

Control cable sizes for all models is, 4G1.5mm

2

, 0.457 O.D. (14/3, SO, 0.53 O.D.)

NOTE: The use of a 4” Break Away Fitting is required with these pumps.

NOTE: A relay is required for use with Moisture Sensor, see Page 25.

PF4SCD

Submersible Cutter Pumps

Specifications