7

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

Pressure Test (If oil has NOT been

drained) -

Oil should be at normal level.

Remove pipe plug (16) from housing (4).

Apply pipe sealant to pressure gauge

assembly and tighten into hole. Pressurize

motor housing to 10 P.S.I.

Use soap solution around the sealed

areas above the oil level and inspect

joints for “air bubbles”. For sealed areas

below oil level, leeks will seep oil. If, after

five minutes, the pressure is still holding

constant, and no “bubbles” /oil seepage

is observed, slowly bleed the pressure

and remove the gauge assembly. Replace

oil. Leek must be located and repaired if

pressure does not hold.

Pressure builds up extremely

fast, increase pressure by

“TAPPING” air nozzle. Too much

pressure will damage seal.

DO

NOT exceed 10 P.S.I.

Oil Replacement

- Set unit upright and

refill with new cooling oil as per table. Fill

to just above motor, (but below capacitor,

on 1 phase units) as an air space must

remain in the top of the housing to

compensate for oil expansion. Apply pipe

thread compound to threads of pipe plug

(16) then assemble to housing (4).

DO NOT

overfill oil. Overfilling

of housing with oil can create

excessive and dangerous hydraulic

pressure which can destroy the

pump and create a hazard.

Overfilling oil voids warranty.

102 oz - Cooling Oil

Recommended Supplier/Grade

BP

Enerpar SE100

Conoco

Pale Paraffin 22

Mobile

D.T.E. Oil Light

Shell Canada

Transformer-10

Texaco

Diala-Oil-AX

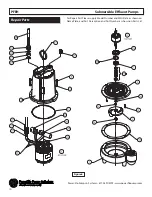

Disassembly & Assembly

Impeller, V-ring and Volute:

Disconnect power. Remove cap screws (8)

and lock washers (9) vertically lift motor,

housing and seal plate assembly from

volute (1). Clean out volute (1) if necessary.

Inspect gasket (12) and replace if cut or

damaged. Clean and examine impeller

(2), for cracks or breakage and replace if

required. To remove impeller (2), remove

impeller nut (10), place a flat screwdriver

in the slot of the end of the shaft to hold

the shaft stationary while unscrewing the

impeller (2).

To reassemble, clean the threads with

thread locking compound cleaner. Apply

removable Loctite® 242 or equivalent to

shaft threads. Screw impeller (2) onto the

shaft hand tight while using a screwdriver

in the slot at the end of the shaft to hold

it stationary. Install impeller nut (10)

and tighten. Rotate impeller to check for

binding. Position gasket (12) on volute

flange and position impeller and motor

housing assembly on volute (1). Position

lock washer (9) on cap screw (8) and screw

into volute (1). Torque to 100 in-lbs. Check

for free rotation of impeller.

Motor, Capacitor, Bearings:

Place pump upright on blocks or piece of

PVC pipe, to avoid resting unit on shaft.

Disassemble volute and impeller as stated

and drain oil from housing. Loosen gland

nut (19) and slide up cord along with

washers (20) and grommet (21). Remove

socket head screws (15) from seal plate

(3). Slide motor housing (4) up cable (18)

until wire connectors (24) are exposed.

NOTE wire connections for reassembly.

Disconnect cable leads from motor leads

and remove motor housing (4) and o-ring

(11), replace if cut or damaged.

Check motor capacitor (29) with an Ohm

meter by first grounding the capacitor

by placing a screwdriver across both

terminals and then removing screwdriver.

Connect Ohm meter (set on high scale) to

terminals. If needle moves to infinity (

∞

)

then drifts back, the capacitor is good. If

needle does not move or moves to infinity

(

∞

) and does not drift back, replace

capacitor (29). Inspect motor winding

for shorts and check resistance values.

Check rotor for wear. If rotor or the stator

windings are defective, the complete

motor must be replaced.

Disconnect capacitor leads from capacitor

(29). Remove v-ring (13) and spacer (14)

from seal plate (3). Remove bolts from

motor stator (6) and lift stator up from

rotor. Loosen conduit bushing (25) and

remove motor rotor, bearing and seal

assembly from seal plate (3).

SEAL -

Remove rotating member (5b),

spring (5c) and retaining ring (5d), from

shaft (see Figure 3). Inspect for signs

of uneven wear pattern on stationary

member, chips and scratches on either

seal face. Replace the complete seal if

any part is damaged.

Figure 2

Service

PFEH

Submersible Effluent Pumps