7

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

Receiving Inspection

Upon receiving the pump, it should be

inspected for damage or shortages.

If damage has occurred, file a claim

immediately with the company that

delivered the pump. If the manual is

removed from the packaging, do not

lose or misplace.

Storage

Any product that is stored for a period

longer than six (6) months from the

date of purchase should be bench

tested prior to installation. A bench

test consists of, checking the impeller

to assure it is free turning and a run

test to assure the motor (and switch

if provided) operate properly. Do not

pump out of liquid.

Location

The design of these pumps allow for

use in decorative water displays. These

pumps should be set in the bottom

of a pit in the horizontal position to

insure submergence at all times. In the

horizontal position, the built-in suction

trap will prevent the unit from pumping

the pit dry, keeping the motor 2/3

submerded, providing adequate cooling.

Pump may be mounted in the vertical

position, but could expose motor

housing if water level is pumped down.

This could cause the motor to overheat

and trip the built-in automatic overload

protector.

Discharge Piping

This is a high capacity low head pump.

It is important to use as few pipe fittings

as posible and of adequate size to

hold pressure loss due to friction to a

minimum. All models have 1-3/4 inch

hose connection discharge and can be

rotated in 90° increments.

WARNING ! - Disconnect power

from pump before handling

or servicing Injury, electrical

shock or death could result.

Pump MUST be grounded in

accordance with the NEC or

CEC and all state province,

local codes and ordinances.

This pump is NOT for use in

swimming pools.

Electrical Connections

The PFU motor is an oil filled, single

phase permanent split capacitor

type with built in automatic overload

protector and does not require a control

box. Connect the white and black wires

of the motor lead to the two line leads

from the power source fused disconnect

switch or breaker box. Connect the green

wire to a ground. See table below for,

cable sizes to reach from power souce to

motor leads, and fuse sizes.

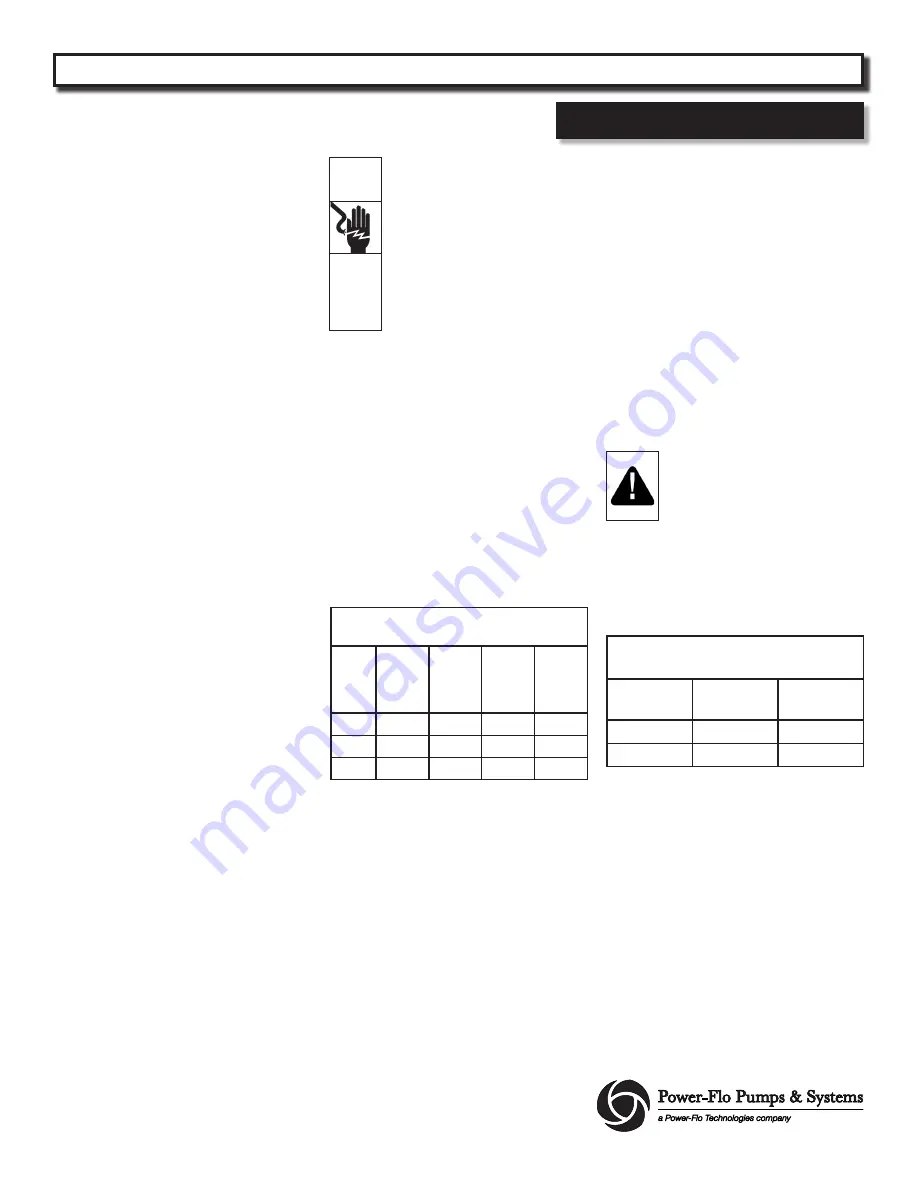

CORD & FUSE SIZES

MAXIMUM CORD LENGTH IN FEET

CORD

SIZE

1/3HP

115V

FUSE:

20 AMP

1/2HP

115V

FUSE:

25 AMP

3/4HP

115V

FUSE:

30 AMP

1HP

230V

FUSE:

25 AMP

14 GA.

70

55

40

100

12 GA.

120

95

55

145

10 GA.

220

145

95

240

Power cable:

The power cable mounted to the pump

must not be modified in any way except

for shortening to a specific application.

Any splice between the pump and the

control panel must be made in

accordance with the electric codes. It is

recommended that a junction box, if

used, be mounted outside the sump

to prevent flooding.

DO NOT USE THE

POWER CABLE TO LIFT PUMP.

Overload Protection:

Single Phase

- The stator in-winding

overload protector used is referred to

as an inherent overheating protector

and operates on the combined effect

of temperature and current. This means

that the overload protector will trip out

and shut the pump off if the windings

become too hot, or the load current

passing through them becomes too high.

IMPORTANT ! -

The overload will then

automatically reset and start the pump

up after the motor cools to a safe

temperature. In the event of an overload,

the source of this condition should be

determined and corrected immediately.

WARNING! - DO NOT LET THE

PUMP CYCLE OR RUN IF AN

OVERLOAD CONDITION

OCCURS !

If current through the temperature sensor

exceeds the values listed, an intermediate

control circuit relay must be used to

reduce the current or the sensor will not

work properly.

TEMPERATURE SENSOR ELECTRICAL

RATINGS

Volts

Continuous

Amperes

Inrush

Amperes

110-120

3.00

30.0

220-240

1.50

15.0

Wire Size:

If longer power cable is required consult

a qualified electrician for proper wire

size.

Receiving & Installation

PFU31, PFU51, PFU71, PFU102, PFU152, PFU202

Submersible Fountain Pumps