9

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

Disassembly & Assembly

Impeller and Volute:

Disconnect power. Disconnect discharge

piping. Remove screen (14) by removing

springs (33) and lifting off. Remove cap

screws (29) and pull volute (1) and gasket

from bearing sleeve (9). Remove set screw

(3), unscrew counter-clockwise impeller

(2) from motor shaft. Replace impeller if

worn or pitted.

Reassemble by placing shims (5) on shaft,

to ensure proper clearance between

impeller (2) and bearing sleeve (9). The

clearance should be approximately .03

inches. Screw impeller (2) clockwise onto

shaft and place set screw (3) in place and

tighten. Place gasket (30) and volute (1)

onto bearing sleeve (9) and insert cap

screws in place and tighten. Replace

screen (14) with springs (33).

IMPORTANT:

For units Dated Jan. 2011 and newer, with

Ball Bearing Design, continue on.

For unites prior to Jan. 2011 with sleeve

design, see pages 11 through 14.

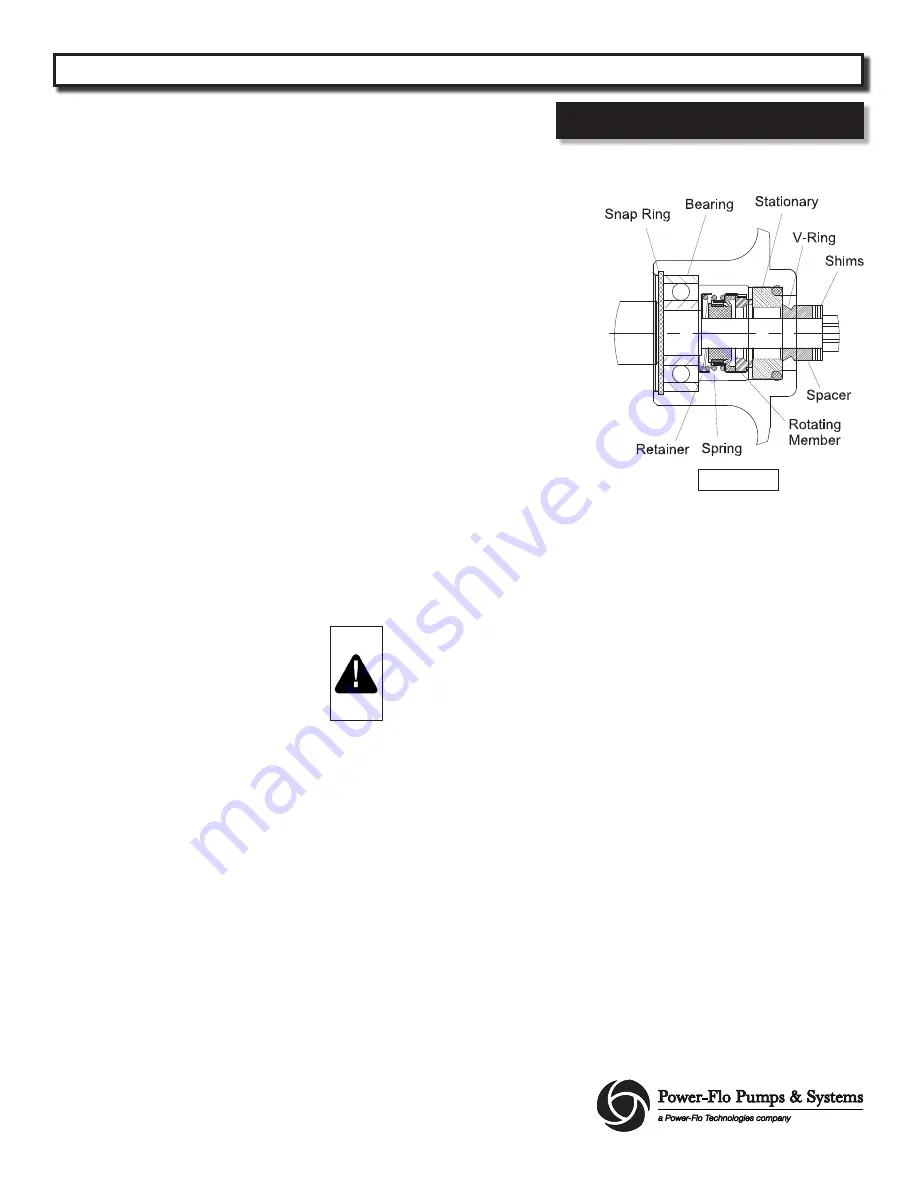

Motor & Shaft Seal:

Remove screen, volute and impeller

as previously stated and drain oil from

housing. Loosen gland nut (17) and slide

it back on cord (18). Remove hex nuts

(20) and lockwashers (21) from studs (28)

and pull housing end (19) from housing

tube (27). Disconnect cord set (18) and

check for damage or cracks, replace if

required. Remove grommet (15), friction

rings (16) from housing end (19), replace

if damaged. Pull housing tube (27) from

bearing sleeve (9). Remove seal spacer

(31) and v-ring (6) from shaft. Loosen

motor screws and pull bearing sleeve (9)

with shaft seal (8) from motor.

IMPORTANT

that you mark location of

overload in relation to bearing sleeve

(9). Remove retaining ring (7) and press

seal assembly (8) out of bearing sleeve.

Replace complete seal if seal shows

signs of uneven wear on seal faces,

chips, or scratches. If replacing seal,

remove stationary by prying out with flat

screwdrive.

Examine o-rings (23) and replace if

damaged. Check motor capacitor (12)

with an Ohm meter by first grounding

the capacitor by placing a screwdriver

across both terminals and then removing

screwdriver. Connect Ohm meter (set

on high scale) to terminals. If needle

moves to infinity (

∞

) then drifts back, the

capacitor is good. If needle does not move

or moves to infinity (

∞

) and does not

drift back, replace capacitor (12). Inspect

motor winding for shorts and check

resistance values. Check rotor for wear. If

rotor or the stator windings are defective,

the complete motor must be replaced.

To test the overload, check the continuity

between the black and white wires.

IMPORTANT! - All parts must be

clean before reassembly.

Handle seal parts with extreme

care. DO NOT damage lapped

surfaces.

To reassemble, clean seal cavity in bearing

sleeve (9) and oil. Lightly oil stationary

member of seal, and with lapped surface

facing motor, press stationary member

with seal pusher tool into bearing sleeve

(9).

Lightly oil

(Do not use grease)

inner

surface of rotating member. With the

lapped surface facing inward, place

rotating member into bearing sleeve (9)

until it seats against stationary member.

Place the spring and retaining ring onto

rotating member. Press bearing (39) into

bearing sleeve (9) and snap ring (7) into

bearing sleeve (9).

Lightly oil

(Do not use grease)

the shaft

on motor (10). Assemble bearing sleeve

(9) onto motor (10), being carfull not to

damage seal. locate overload as noted (or

at the 11 o’clock position as viewed from

motor end), with the four motor bolts.

Place capacitor (12) into bracket (25) if

removed and secure with screw. Connect

flag terminal from motor and terminal

boot (13) to capacitor (12).

Place one o-ring (23) into groove on

bearing sleeve (9) being careful not to

damage the o-ring. Slide housing tube

(27) onto bearing sleeve (9). Place o-ring

(23) into groove on housing end piece

(19) and place end piece onto housing

tube (27). Place pump support (22) onto

lower studs (28) and lockwashers (21) and

hex nuts (20) onto studs and tighten.

Place v-ring (6) and seal spacer (31) onto

shaft until seated. Assemble sceen, volute

and impeller as described.

Service

Figure 1

PFU31, PFU51, PFU71, PFU102, PFU152, PFU202

Submersible Fountain Pumps