SS3L / SS3R Series

www.powergenex.com

51

12.

Maintenance / Service

12.1.

Preliminary Check Points

12.1.1.

Voltage

- The positioner commonly requires 4-20mA @ 24VDC for operation.

- Voltage drop (impedance): Without HART – 8.7VDC (435Ω @ 20mA)

With HART – 9.4VDC (470Ω @ 20mA)

12.1.2.

Electrical Connections

Check polarities (+, -) of 4-20mA input signal definitely and make the electrical connections.

12.1.3.

Pneumatic Connections (see 8.1, 8.2)

12.1.4.

Supply Air Quality

A supply air should be definitely clean and compressed free of water, moisture or oil in

conformance with IEC 770 and ISA-7.0.01.

12.2.

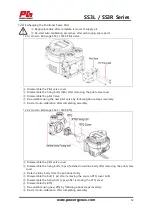

Module Parts

① RTQ Coil Assembly (spare part No. 12)

② Pilot Valve Assembly (spare part No. 5)

③ PCB Control Board Assembly (spare part No. 3)

12.3.

Re-setting of Potentiometer (spare part No. 14a, 14b)

It is necessary to adjust a setting of potentiometer as below when a gear position is moved due

to user’s carelessness. For reference, 0~10kΩ potentiometer is installed into the SS2 positioner.

① Dis-install the electronic card from the SS3 positioner and make the markings on two gears

match with each other.

② Move the feedback lever to 50% position and adjust a potentiometer so that it can reach

nearly 5kΩ.

③ Re-install the SS3 positioner onto the valve and re-perform auto-calibration.