SS3L / SS3R Series

www.powergenex.com

53

13.

Troubleshooting

13.1.

Error Codes and Recommended Actions

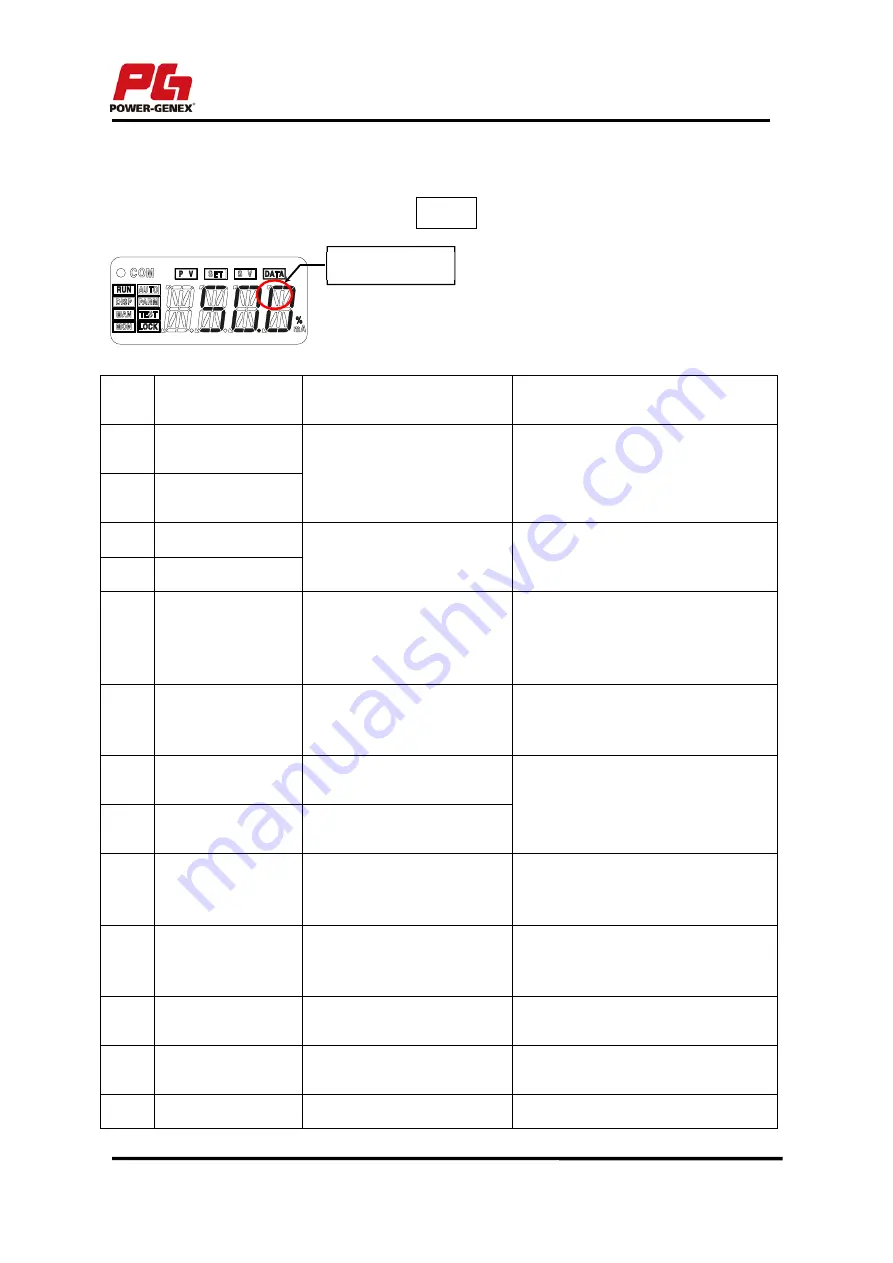

If the positioner doesn’t work properly and

on LCD blinks, try to take action as below.

Error

Code

Cause

Symton

Action

CMLO

Low input current

(3.7mA)

Data on LCD are shown too dim

or too bright.

Re-check 4 – 20mA input signals.

CMHI

High input current

(20.5mA)

IGMI

Down Speed Long

Slow operation

The actuator is too big.

Use the air volume booster.

IGMX

Up Speed Long

H/RX

HART Rx Error

HART signal failure

Re-set and re-connect will be done after

2.5 seconds, but it is necessary to check

the communication system in case of a

continuous error.

MONT

Operating angle out

of range

MONT is shown during step 4 and

an auto-calibration process is

finished without completion.

Re-install the SS2L / SS2R positioner.

LOTT

Bias Low

The valve is not closed or moves

slowly.

Loosen a valve packing.

HITT

Bias High

The valve is not open or moves

slowly.

FBFT

Feedback error

(0 - 1%)

PM00 is shown at step 4 and an

auto-calibration is finished

without completion.

Defectiveness of potentiometer socket

contact or PCB board

FBSM

Feedback error

(2 - 9%)

The operating stroke is too small

and the valve doesn’t work

smoothly.

Re-install the potentiometer and increase

the operating angle of the feedback lever.

BAD

PST error

BAD is shown.

Check the valve or increase the response

time of PST.

PONT

Potentiometer Error

Problem of potentiometer

Check the potentiometer

(Potentiometer Ass’y, Board)

RTQ

Coil Error

Problem of coil

Check the coil assembly.

DATA

DATA blinks