14

Installing accessories

– cont’d

NOTES:

a) Make sure the correct collet is used for the

accessory. If collet is too large, replace the

collet with the next smaller size.

b) Insert accessory at least

3

/

4

" into the collet.

5.

Press the spindle lock button and engage it

in the spindle. While holding the spindle

lock button down, hand-tighten the collet by

turning it clockwise.

NOTE:

Do not use pliers to tighten the

collet nut. Use the small wrench (4)

supplied. Over tightening will cause

damage to the tool.

6.

Pull on the accessory to ensure it is

securely in place.

WARNING:

When using any new

accessory for the first time, particularly wire

wheels, bristle brushes and grinding stones, run

the tool at full speed for one minute to remove

any loose wires, bristles or stone particles.

During this initial run-up, always wear a face

shield and make sure you are NOT in line

with the rotating accessory to avoid injury

caused by flying debris.

SELECTING PROPER SPEEDS

Different speeds are required depending upon

the type of operation being performed. The

following chart outlines those basic speeds:

For safety reasons, the operator must read

the sections of this Owner’s Manual entitled

"GENERAL SAFETY WARNINGS", "POWER

TOOL SAFETY", "SPECIFIC SAFETY

RULES", "EXTENSION CORD SAFETY" and

"SYMBOLS" before using this rotary tool.

Verify the following every time the rotary

tool is used:

1.

Safety glasses, safety goggles, or face

shield are being worn.

2.

Accessory is in good condition and not

damaged in any way.

3.

Workpiece is properly secured.

Failure to observe these safety rules will

significantly increase the risk of injury.

WARNING

!

OPERATION

SPEED

Cutting metal

5

–MAX

Sanding wood

5

–MAX

Cutting hard metal

5

–MAX

Engraving metal

4

–5

De-burring

4

–5

Drilling holes

4

–5

Removing rust

3

–4

Sharpening

3

–4

Polishing

1

–2

!

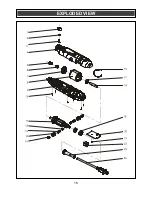

ASSEMBLY AND OPERATING

Fig. 4

Summary of Contents for JD3315U

Page 16: ...16 EXPLODED VIEW...