4

ELECTRICAL SAFETY

GENERAL SAFETY WARNINGS

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT

.

WARNING:

Dust that is created by power sanding, sawing, grinding,

drilling, and other construction activities may contain chemicals that are

known to cause cancer, birth defects, or other genetic abnormalities. These

chemicals include:

Lead from lead-based paints

Crystalline silica from bricks, cement, and other masonry products

Arsenic and chromium from chemically treated lumber

The level of risk from exposure to these chemicals varies, according to how

often this type of work is performed. In order to reduce exposure to these

chemicals, work in a well-ventilated area, and use approved safety

equipment, such as a dust mask that is specifically designed to filter out

microscopic particles.

!

WARNING:

To avoid electrical hazards, fire hazards or damage to the

tool, use proper circuit protection.

This tool is wired at the factory for 120 V AC operation. It must be

connected to a 120 V AC, 15 A circuit that is protected by a time-delayed

fuse or circuit breaker. To avoid shock or fire, replace power cord

immediately if it is worn, cut or damaged in any way.

SAVE THESE INSTRUCTIONS FOR REFERENCE

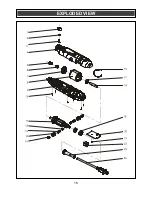

Summary of Contents for JD3315U

Page 16: ...16 EXPLODED VIEW...