23

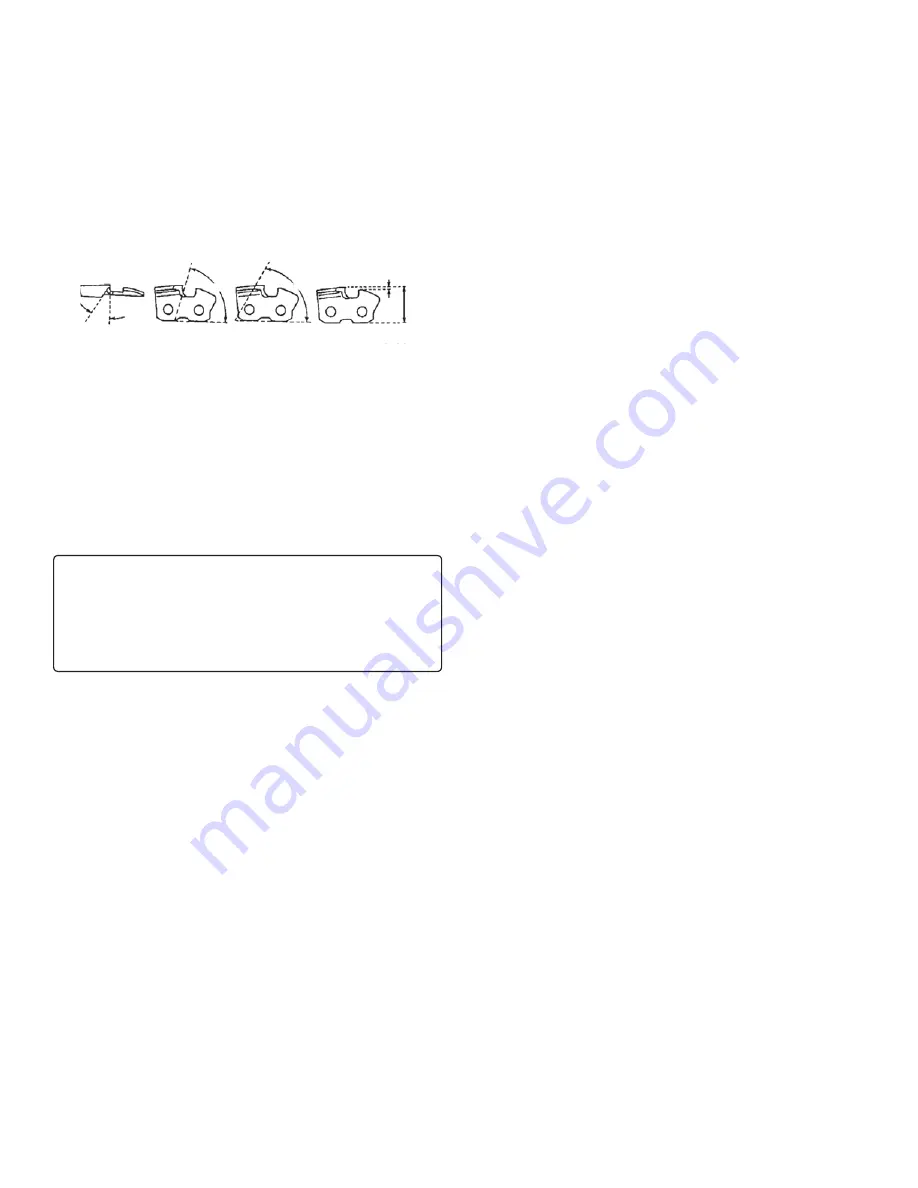

Correct angle of edge grinding

30-degree

A

C

D

80-degree

60-degree

0.64mm

Parallel lines

The correct angle of edge grinding is shown in the figure:

A. 30-degree top angle;

B. 80-degree lateral angle;

C

60-degree cutting angle for the top side;

D. Depth measurement: 0.64mm.

The following errors may result in increase of bounce:

1) The top angle is too large.

2) The lateral angle is too small.

3)

The file diameter is too small.

4) The depth is too large.

Attention

The angle parameters are suitable for Oregon 91VS,

91VG and Carlton N1C-BL chains. For the angles of

other kinds of chains, refer to the instructions of the

manufacturer.

Cleaning of guide plate slot

Drive the chain ring to clean sawdust in the guide plate slot.

Keep the lower drive edge sharp.

•

Install the chain and immerse it in oil.

•

After chain filing on the guide plate, fill enough oil, and

slowly rotate the chain to clean iron chips before use.

•

The wear of the chain and guide plate will be increased if

the chain saw with the slot full of iron chips is used.

•

If resin is adhered to the chain, clean the chain with

kerosene or immerse the chain in oil.