16

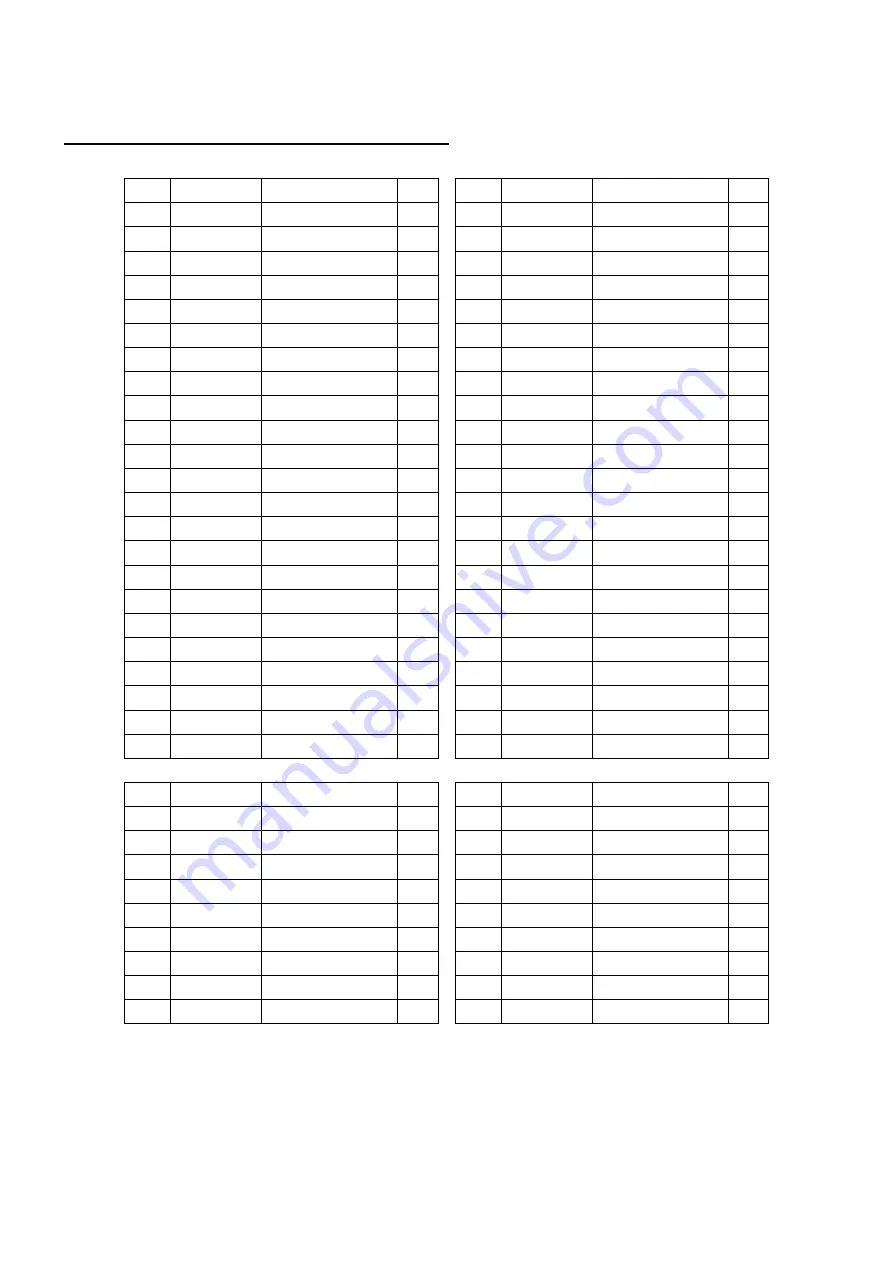

PLATE COMPACTOR PARTS LIST

Item

Stock#

Description

Qty

Item

Stock#

Description

Qty

1

PS8810-001

Engine

1

24

PS8810-024

Spring Gasket

2

2

PS8810-002

Key

1

25

PS8810-025

Medium Flat Gasket

2

3

PS8810-003

Clutch Assembly

1

26

PS8810-026

Belt Cover

1

4

PS8810-004

Conical Flat Gasket

1

27

PS8810-027

Locked Nut

6

5

PS8810-005

Spring Gasket

1

28

PS8810-028

Shock Absorber

4

6

PS8810-006

External hexagon bolt

1

29

PS8810-029

Shock Absorber

4

7

PS8810-007

External hexagon bolt

2

30

PS8810-030

Nut

4

8

PS8810-008

Enlarged Flat Gasket

6

31

PS8810-031

Bottom Plate

1

9

PS8810-009

Handle glues heath

2

32

PS8810-032

Engine Support Plate

1

10

PS8810-010

Flat Gasket

2

33

PS8810-033

Nut

2

11

PS8810-011

Lower handle

1

34

PS8810-034

External hexagon bolt

2

12

PS8810-012

Locked Pin Assembly

2

35

PS8810-035

Exciter

1

13

PS8810-013

Upper handle

1

36

PS8810-036

Flat Gasket

6

14

PS8810-014

Throttle Line Assembly

1

37

PS8810-037

Spring Gasket

6

15

PS8810-015

Locked Nut

2

38

PS8810-038

Inner Hexagon bolt

6

16

PS8810-016

Flange Bolt

2

39

PS8810-039

Belt

2

17

PS8810-017

Flat Cross Bolt

4

40

PS8810-040

External hexagon bolt

4

18

PS8810-018

Handle Damper

2

41

PS8810-041

Enlarged Flat Gasket

4

19

PS8810-019

Locked Nut

8

20

PS8810-020

External hexagon bolt

2

21

PS8810-021

Handle lower Damper

2

22

PS8810-022

Flat Gasket

8

23

PS8810-023

External hexagon bolt

2

2

.

Item

Stock#

Description

Qty

Item

Stock#

Description

Qty

1

PS8810-101

Case Cover(shut-off)

1

10

PS8810-110

Oil Drainage Bolt

1

2

PS8810-102

“O” Ring

1

11

PS8810-111

Case Cover (Pulley)

1

3

PS8810-103

Bearing

2

12

PS8810-112

Oil Seal

1

4

PS8810-104

Vibrating Case

1

13

PS8810-113

Pulley

1

5

PS8810-105

Eccentric Shaft

1

14

PS8810-114

Spring Gasket

1

6

PS8810-106

Key

1

15

PS8810-115

Enlarged Flat Gasket

1

7

PS8810-107

Inner Hexagon bolt

12

16

PS8810-116

Inner Hexagon bolt

1

8

PS8810-108

Flat Gasket

12

9

PS8810-109

Copper Gasket

1

Summary of Contents for PS8810

Page 2: ...2 ...

Page 15: ...15 PLATE COMPACTOR EXPLODED VIEW 1 2 ...

Page 17: ...17 EXPLODED VIEW AND PARTS LIST ENGINE ...

Page 21: ...21 ...