Operating Instructions, Form No. 102997, Back sheet 1 of 3

SAFETY PRECAUTIONS (Continued)

PUMPS

●

Do not exceed the hydraulic pressure rating noted on the pump nameplate or tamper with the internal

high pressure relief valve. Creating pressures beyond rated capacities can result in personal injury.

●

Retract the system before adding oil to prevent overfilling the pump reservoir. An overfill can cause

personal injury due to excess reservoir pressure created when cylinders are retracted.

PULLER

●

Align the puller on the same centerline as the part being removed. Failure to align parts correctly can

result in a dangerous operating situation because of the high hydraulic pressures used.

●

Align puller jaw and pushing adapter set-ups on the same centerline as the part being removed. Failure to

align parts correctly can result in a dangerous operating situation because of the high hydraulic

pressures used.

●

Always support the object being pulled.

●

Stand behind and to one side of the puller when applying pressure.

●

Do not try to pull components that are thicker than 4" at the maximum opening of 48"or require the jaws

to be opened to more than 48".

SET-UP INSTRUCTIONS

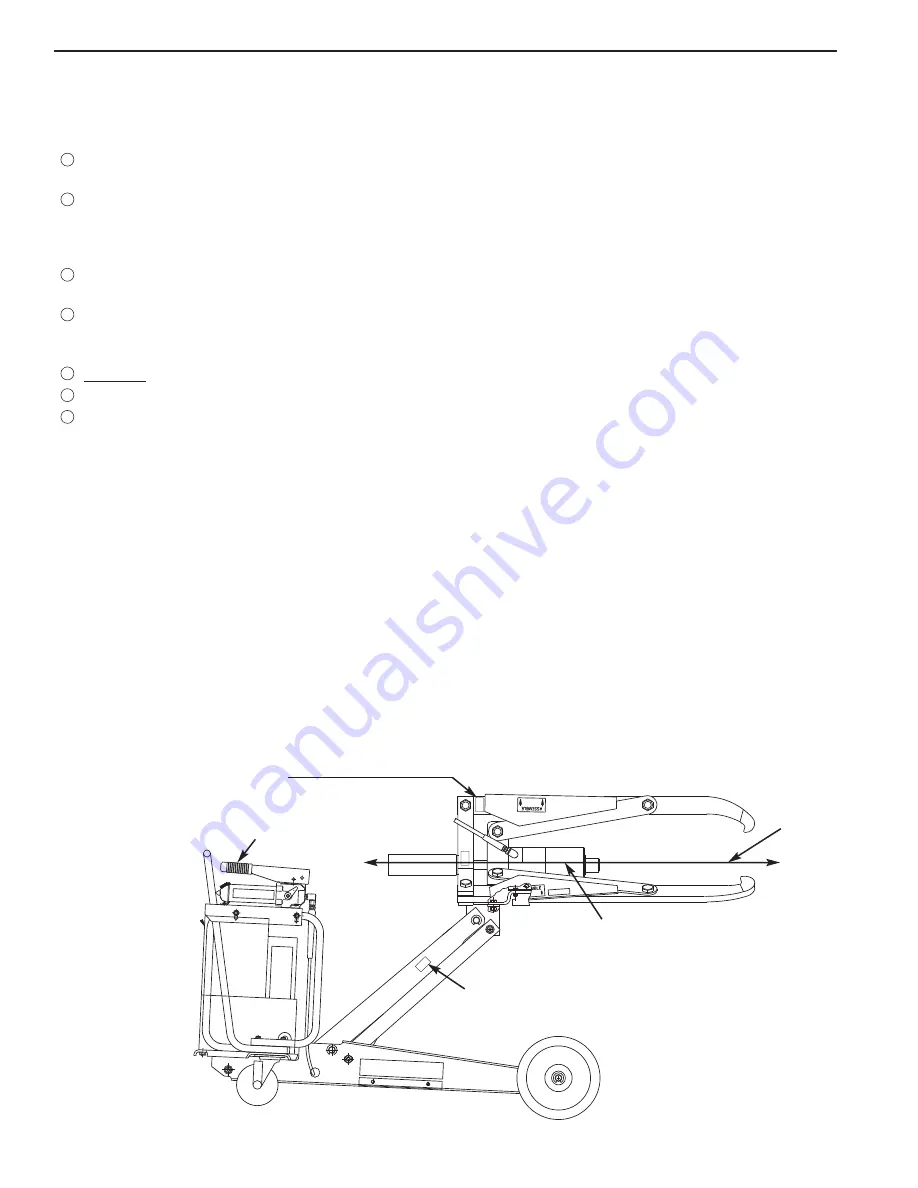

VERTICAL SET-UP

Refer to Figure 1.

The head and pulling jaw assembly on this puller is designed to compensate for some degree of error in a job set-up.

Note: Because of this feature, the head and puller jaw assembly may rest at a slight upward angle.

1. Adjust vertical set-up by using the hand pump shown in Figure 1. The centerline of the object being pulled must

be on the same centerline as the puller head.

2. Align the puller horizontally and vertically as close as possible to the same centerline as the object to be pulled.

FIGURE 1

HAZARD:

Crushing and cutting

of fingers and hand.

Puller Head

Centerline

Centerline

of object to

be removed

HAZARD:

Crushing of toes

or foot

Hand Pump