4. Roll off the sanding sheet from the dust box.

5. Push new the sanding sheet tightly against the

bottom side of the sanding plate.

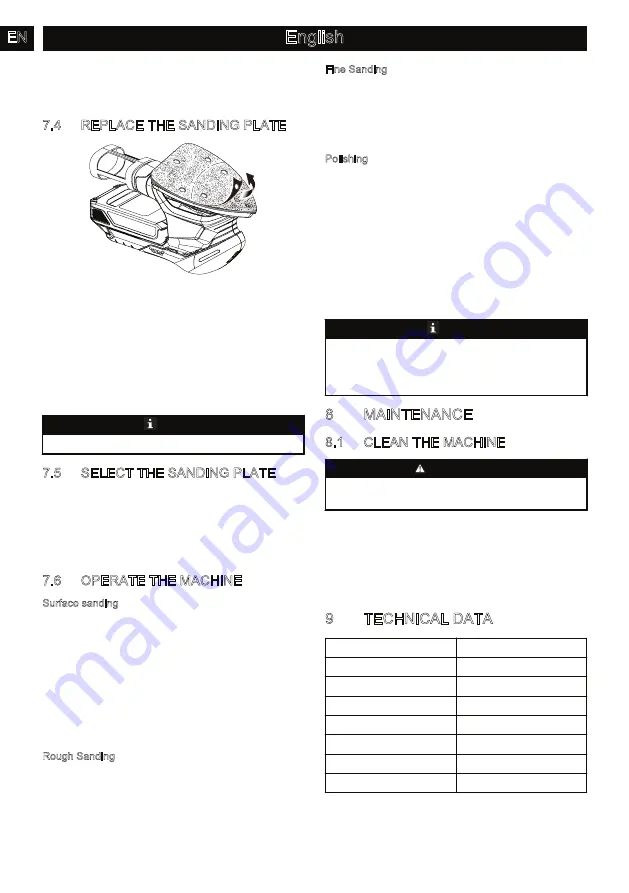

7.4

REPLACE THE SANDING PLATE

1. Pull off the sanding sheet or the polishing

accessory.

2. Loosen the four screws fully and remove the

sanding plate.

3. Clean the top side of the new sanding plate. Apply a

thin layer of synthetic grease to the outer ring

hatched grey.

4. Attach the new sanding plate and tighten the four

screws again.

NOTE

Replace a damaged sanding plate immediately.

7.5

SELECT THE SANDING PLATE

The machine can be equipped with sanding plate with

different hardness for different operation.

• Medium (black): used for all sanding work,

• Soft (grey, accessory): used for intermediate and

fine sanding, incl. on convex surfaces.

7.6

OPERATE THE MACHINE

Surface sanding

1. Start the machine.

2. Put it with the complete sanding surface on the

surface to be worked and move the machine with

moderate pressure over the workpiece.

The removal capacity and the sanding pattern are

mainly determined by the selection of the sanding

sheet, the preselected orbital stroke rate and the

applied pressure.

Use only initial sanding accessories.

Rough Sanding

1. Attach a sanding sheet with coarse grain.

2. Apply only light pressure to the machine so that it

runs at a higher stroke rate and high material

removal is achieved.

Fine Sanding

1. Attach a sanding sheet with fine grain.

2. By lightly varying the application pressure or

changing the orbital stroke rate, the sanding plate

stroke rate can be reduced whereby the orbital

action is maintained.

Polishing

1. Select a low orbital stroke rate (level 1 – 4) when

polishing in order to avoid heating up the surface

excessively.

2. Apply the polish onto a somewhat smaller surface

than you intend to polish. Work the polishing agent

in with a suitable polishing tool applying it crosswise

or with circular motion and moderate pressure.

3. Clean the polishing accessories regularly to ensure

good polishing results. Wash out polishing

accessories with a mild detergent and warm water;

do not use paint thinner.

NOTE

Do not allow the polishing agent to dry out on the

surface, otherwise the surface can become damaged.

Do not subject the surface to be polished to direct

sunlight.

8

MAINTENANCE

8.1

CLEAN THE MACHINE

CAUTION

The machine must be dry. Humidity can cause risks of

electrical shocks.

• Clear the unwanted material out of the air vent with

a vacuum cleaner.

• Do not spray the air vent or put the air vent in

solvents.

• Clean the housing and the plastic components with

a moist and soft cloth.

9

TECHNICAL DATA

Voltage

20 V

Speed

Single speed

Orbits Per Minute

11,000 min

-1

Orbit diameter

0.03 " (0.8 mm)

Sanding plate dimension

90*140 mm

Weight (without battery)

0.75 lbs

Battery model

BAP series

Charger model

CAP sereis

8

English

EN