20

4111-0044 — June 2021

© 2021 Systems, LLC

8. Fully close the down speed flow control valve

by turning clockwise. Then, set the down speed flow

control valve by incrementally opening the valve until

the leveler takes 15-20 seconds to descend from

stored to full below dock position.

9. Once ideal down speed flow control setting is

achieved, lock the adjustment in place by tightening

the set screw (

C

) on the adjustment knob.

10. Raise the maintenance props to the stored

position and tighten all hardware with wrench.

11. Lower the leveler to a 45 degree angle.

12. Cycle lip by pressing the LOWER and LIP

buttons together to lower the lip, then press the

RAISE and LIP buttons together to raise the lip. Lip

cylinder is now purged.

13.

Raise leveler to stored position and top off

hydraulic fluid as required.

1. Using an external lifting device, support the RCR

leveler in the stored position, with the maintenance

props lowered in the maintenance position and all

hardware tightened by wrench.

2. Lock-out and tag-out the leveler.

3. New equipment only: Remove shipping bands

from hoist cylinder(s).

4. New equipment only: Fill powerpack fluid

reservoir with hydraulic fluid. See page 28 for

acceptable fluid specifications.

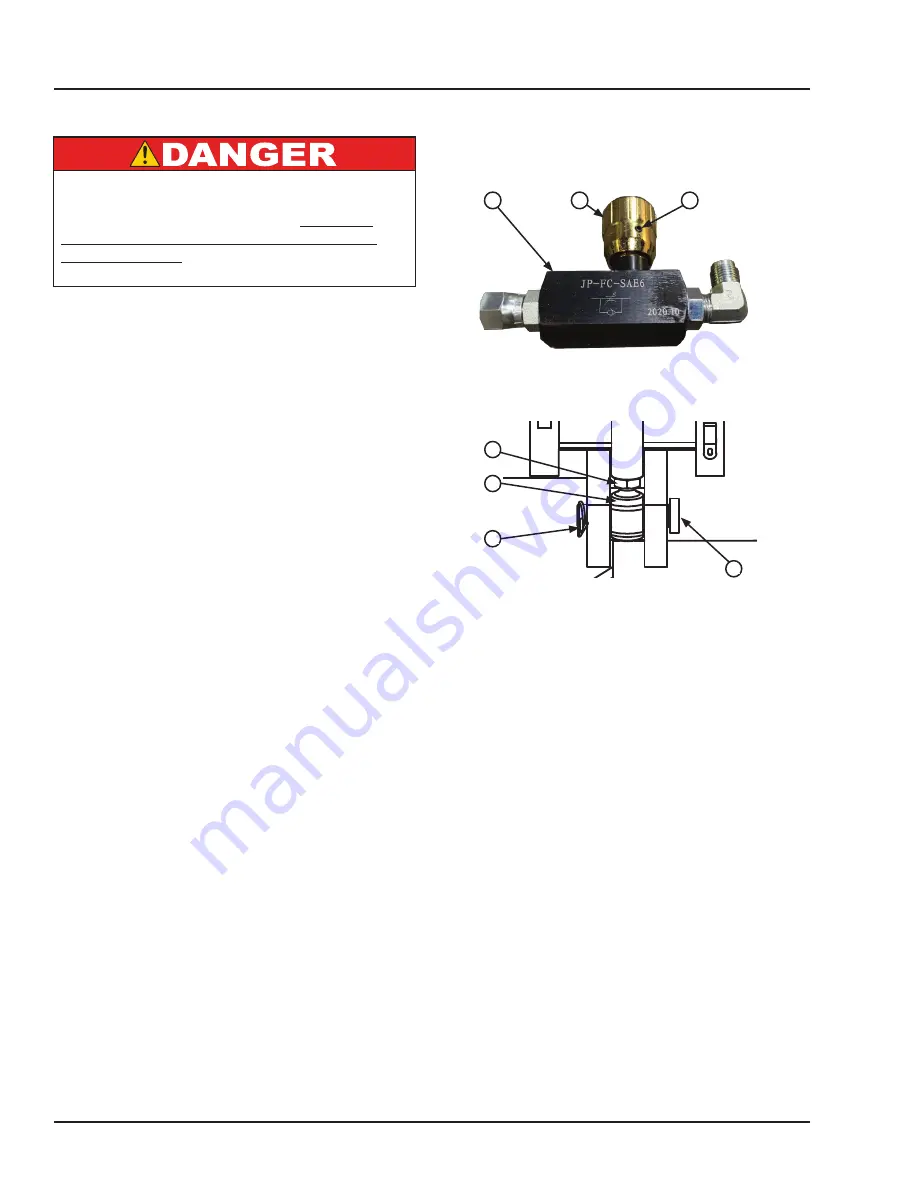

5. Fully open the down speed flow control valve (

A

)

by turning knob (

B

) counter-clockwise (see Figure

19). Loosen set screw (

C

) to turn knob. Flow control

valve location varies depending on options; see

Component Identification on pages 9-11 for location

or contact Technical Services.

6. With the cylinder pin(s) (

F

) removed from the

embed/carriage, restore power to the dock leveler.

Then cycle the hoist cylinder(s) up and down at least

six times using the leveler’s own hydraulic power.

Ensure the cylinder rod(s) smoothly extend/retract.

7. Reconnect the hoist cylinder yoke(s) to the base

of the embed or carriage by completing the following

steps (see Figure 20):

a. Fully extend the hoist cylinder by pressing

and holding the RAISE button until the rod stops

extending and the powerpack goes into pressure

relief.

b. Using the external lifting device, position the

leveler platform so that it is leaning 4 degrees

towards the inside of the building/dock.

c. With the platform leaning 4 degrees towards

inside, loosen the jam nut (

D

) and adjust the

yoke (

E

) so that the cylinder pin (

F

) easily slides

through both the trunnion and yoke.

d. Install and lock rue clip (

G

) into place.

A— Flow Control Valve

B— Adjusting Knob

C— Set Screw

D— Jam Nut

E— Yoke

F— Hoist Cylinder Pin

G— Rue Clip

INSTALLATION

Purging Air From RCR Hydraulic System & Adjusting Yoke

If the equipment being serviced is a new start-

up, opened to atmosphere, or lifted manually, air

will enter into the hydraulic system. Whenever

this happens, air must be fully purged from the

hydraulic system.

Failure to do so will result in

death or serious injury.

TOLERANCES

(UNLESS OTHERWISE NOTED)

FRACTIONAL:

1/32"

DECIMAL:

.00 =

.01"

.000 =

.005"

ANGULAR:

1

MATERIAL

DRAWN BY

CHECKED BY

DRAWING NO.

DATE

johnschlintz

1/27/2020

VS-VSH

PARTS

EXPLODED

VIEW PG 40

2021

P O W E R A M P

M C G U I R E

D L M

S

S Y

Y S

S T

T E

E M

M S

S

L o a d i n g D o c k E q u i p m e n t

This print is the property of Systems, LLC and represents a proprietary article in which Systems, LLC retains any and all

patent and other rights, including exclusive rights of use and/or manufacture and/or sale. Possession of this print does

not convey any permission to reproduce, print or manufacture the article or articles shown therein, such permission to be

granted only by written authorization signed by an officer or other authorized agent of Systems, LLC thereof.

STOCK NO.

REV A - ECN 18-066

C

B

A

Figure 19

Figure 20

F

D

E

G

Summary of Contents for RCR Series

Page 25: ...23 4111 0044 June 2021 2021 Systems LLC OPERATION This page intentionally left blank ...

Page 38: ...36 4111 0044 June 2021 2021 Systems LLC PARTS Platform Hydraulic Hoses C A G F E D B H ...

Page 58: ...56 4111 0044 June 2021 2021 Systems LLC This page intentionally left blank MISCELLANEOUS ...