17

4111-0008 — April 2017

June 2017

INSTALLATION

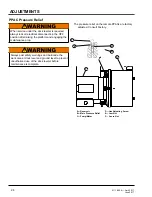

Rod Eye adjustment & New installation

1. Support the leveler with the maintenance props.

Lock out the storage prop with the prop pin and

clip.

2. Lock-out and tag-out the leveler.

3. Remove lower hoist cylinder mounting pin.

4. Remove one of two screws holding the stored

limit switch. Swivel stored limit switch away from

storage prop.

5. Restore power to the leveler. Confirm the BLUE

stored indicator light is no longer illuminated.

6. Cycle the hoist cylinder up and down at least

once to make cylinder is fully extended.

7. Rod eye should be adjusted so the center of the

rod eye is half way below the center of the hole

of the embed. After adjusted tighten jam nut.

8. To center the rod eye with the embed tap the

lower button until the pin (lube pin) can be

installed. Use washers to keep the rod eye

centered in the opening.

9. After pin has been installed, store maintenance

props and prop pin and clip, test the leveler for

operation.

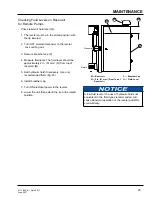

Purging Air From The VS Hydraulic

System.

1. The unit must be supported in the stored position

with the storage prop and maintenance props in

their in service positions. Lock out the storage

prop with the prop pin and clip.

2. Lock-out and tag-out the leveler.

3. Disconnect the lower hoist cylinder mounting pin.

4. Remove one of two screws holding the stored

limit switch. Swivel stored limit switch away from

storage prop (SEE PAGE 28).

5. Open down speed flow control valve (counter

clockwise). Write down the adjustment. Down

speed control valve is located on hoist cylinder

(SEE PAGE 28).

6. Restore power to the leveler. Confirm the

BLUE Leveler Stored indicator light is no longer

illuminated.

7. Cycle the hoist cylinder up and down at least 6

full times using the LOWER and RAISE buttons.

8. Connect the hoist cylinder to the base of the

embed is channel.

9. Remove the prop pin and clip, return the

maintenance props to the stored position.

10. Adjust down speed flow control to factory

settings. The settings is a leveler down speed

of 15-20 seconds from stored to full below dock

position.

11. The lip cylinder is self purging. Lower the leveler

to a 45 degree angle. Cycle lip by depressing

the LOWER and LIP button together to lower the

lip. Press the raise and lip button together to

raise the lip. WARNING: Stay clear of lip at all

times as it may fall if air is present in the system.

12. Make sure all air is purged from the hydraulic

cylinders after set-up and any time air is

introduced to the system.

File Name: 1751-0138 Rev B

Decal Size: 4 x 2

CRUSH HAZARD

DO NOT REMOVE

hydraulic cylinder until leveler is

safely supported by maintenance prop. Refer to

owner’s/user’s manual for proper maintenance

procedure. Failure to comply will result in death or

serious injury.

1751-0138 Rev B

File Name: 1751-0229 Rev E

Decal Size: 4 x 1

Summary of Contents for VS series

Page 44: ...42 4111 0008 April 2017 June 2017 Centra Power Hydraulic Components PARTS A B E D F G I H C ...

Page 47: ...45 4111 0008 April 2017 June 2017 This page was left intentional left blank PARTS ...

Page 53: ...51 4111 0008 April 2017 June 2017 PARTS This page was left intentional left blank ...