18

4111-0008 — April 2017

June 2017

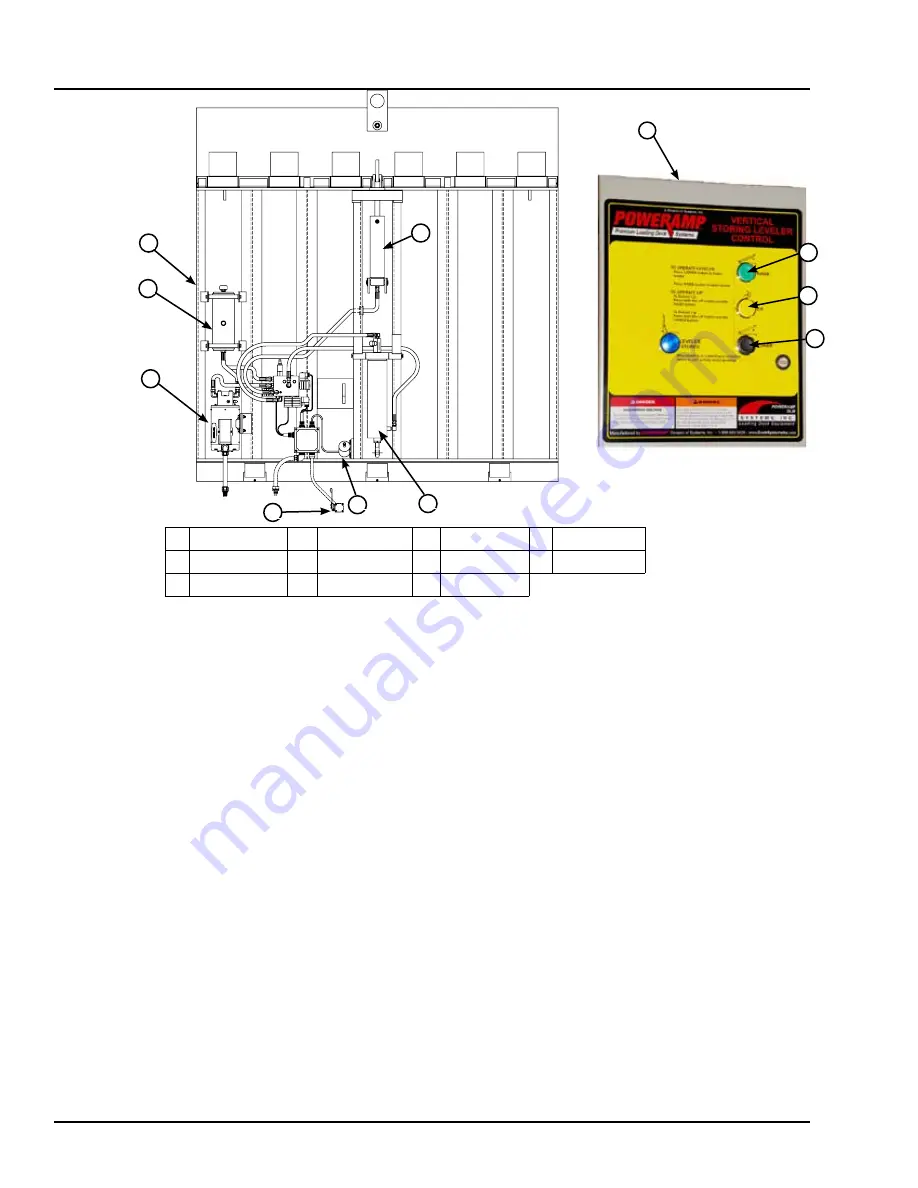

OPERATION

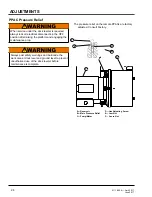

When the leveler is operated an electric motor is

activated (C) which, drives a hydraulic pump. The

hydraulic pump forces oil into the platform cylinder(s)

(D), causing the platform to rise or lower. Releasing

the button will stop the platform from moving (except in

the float mode).

To lower the vertical leveler the LOWER (L) button

will be depressed. The leveler Hoist Cylinder (D) will

extend, an electrical solenoid (H) will activate and

disengage the Storage Prop( not shown). The solenoid

will hold the Storage Prop disengaged for a short

period of time to allow the leveler to lower. The leveler

will start to lower down to the transport vehicle. When

the leveler is about 12” to 15” above dock height the

leveler goes into float mode. You will also hear the

motor make a different sound and you no longer need

to hold the LOWER button. This feature is designed

into the operation of the leveler to allow for the

floating/vertical motion of the transport vehicle during

loading and unloading.

To lower the lip the vertical leveler must not be in the

stored position. Depress the LOWER (L) button and

LIP (K) button at the same time and the motor will

shut off and the lip will lower. To raise the lip, depress

the RAISE (J) button and the LIP(K) button the motor

will run and the lip will raise. The LIP push button is

inactive while the leveler is in the float mode. Also

when leveler is stored.

* Some models are equipped with multiple cylinders.

Theory

A

Control Box

D

Hoist Cylinder

H

Solenoid

K Lip Button

B

Platform

F

Limit Switch

I

Lip Cylinder

L

Lower Button

C

Power Pack

G

Reservoir

J

Raise Button

C

B

I

F

G

H

D

J

L

A

K

Summary of Contents for VS series

Page 44: ...42 4111 0008 April 2017 June 2017 Centra Power Hydraulic Components PARTS A B E D F G I H C ...

Page 47: ...45 4111 0008 April 2017 June 2017 This page was left intentional left blank PARTS ...

Page 53: ...51 4111 0008 April 2017 June 2017 PARTS This page was left intentional left blank ...