24

4111-0008 — April 2017

June 2017

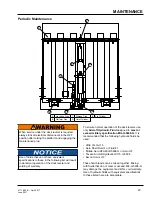

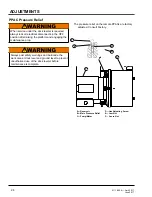

MAINTENANCE

Regular maintenance must be performed on a weekly

and quarterly schedule. Follow all safety precautions.

Weekly Maintenance

• Operate the dock leveler through the complete

operating cycle, making sure the dock leveler floats

in the working zone approximately 15 inches

before horizontal.

• Verify lip operates up and down.

• Lock the storage prop with the prop lock pin and

clip. Put the Maintenance Props in service position.

• Lock out and tag out the dock leveler before

cleaning the dock.

• Remove any debris or foreign objects from the lip,

rear hinges and limit switch area.

• Inspect signs,warning decals and placards.

Replace if damaged or missing.

• Inspect bumper for wear, tears or missing, replace

as required.

Quarterly Maintenance

• Weekly Maintenance

• Lubricate the following areas with light weight

machine oil:

(A)— Lip hinge area unless equipped with grease

fittings (apply oil to the top of the entire

length of lip hinge when platform is in the

stored position and lip is folded)

(B)— Platform hinge area (apply oil to top of all

platform hinges when platform is in the

stored position.)

(C)— Apply a light oil to the Storage prop pins.

(D)— Grease the hoist cylinder grease fitting and

pin.

(E)— Apply a light oil to the Lip Cylinder pins.

Yearly Maintenance

• Quarterly Maintenance

• Change hydraulic oil as needed (may be required

more often depending upon conditions.)

Failure to properly lubricate the dock leveler will

cause abnormal operation of the leveler.

A

B

TOLERANCES

(UNLESS OTHERWISE NOTED)

FRACTIONAL:

1/32"

DECIMAL:

.00 =

.01"

.000 =

.005"

ANGULAR:

1

MATERIAL

DRAWN BY

CHECKED BY

DRAWING NO.

DATE

mikemartin

2/4/2015

vs prop

P O W E R A M P

M C G U I R E

D L M

S Y S T E M S, I N C.

L o a d i n g D o c k E q u i p m e n t

This print is the property of Systems, Inc. and represents a proprietary article in which Systems, Inc. retains any and all

patent and other rights, including exclusive rights of use and/or manufacture and/or sale. Possession of this print does

not convey any permission to reproduce, print or manufacture the article or articles shown therein, such permission to be

granted only by written authorization signed by an officer or other authorized agent of Systems, Inc. thereof.

STOCK NO.

FIG.“A”

FIG.“B”

File Name: 1751-0230 Rev E

Decal Size: 3.75 x 6.25

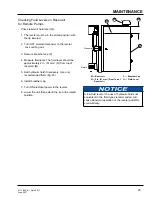

CRUSH HAZARD

DO NOT WORK UNDER OR IN FRONT OF

DOCK LEVELER

unless ALL props have been

properly positioned and secured. First position

side maintenance prop(s) and secure with screw

and nut as shown in figure “A” below. Then

position storage prop and secure with prop lock

pin as shown in figure “B” below. Failure to do so

will result in death or serious injury. Refer to

owner’s/user’s manual for proper procedure.

Prop Lock

Pin

Storage

Prop

Stored

Position

Maintenance

Position

Screw and Nut

Maintenance

Prop

1751-0230 Rev E

NOTE: Apply grease to lip hinge grease fittings if

equipped.

Inspect the following for damage or abnormal wear:

• Check welds for cracks.

• Coils for cracks and bent valves.

• Lower pin and mounting holes.

• Rear hinge pins and cotter pins.

• Stored limit switch is securely mounted.

• Rue clip is in manual lock position.

• J box for water damage.

•

Inspect hoses,cylinders, fittings and power pack.

• Control box and conduit for damage

•

Check fluid level when the unit is in the stored

position.

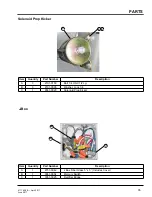

Summary of Contents for VS series

Page 44: ...42 4111 0008 April 2017 June 2017 Centra Power Hydraulic Components PARTS A B E D F G I H C ...

Page 47: ...45 4111 0008 April 2017 June 2017 This page was left intentional left blank PARTS ...

Page 53: ...51 4111 0008 April 2017 June 2017 PARTS This page was left intentional left blank ...