5

4111-0008 — April 2017

June 2017

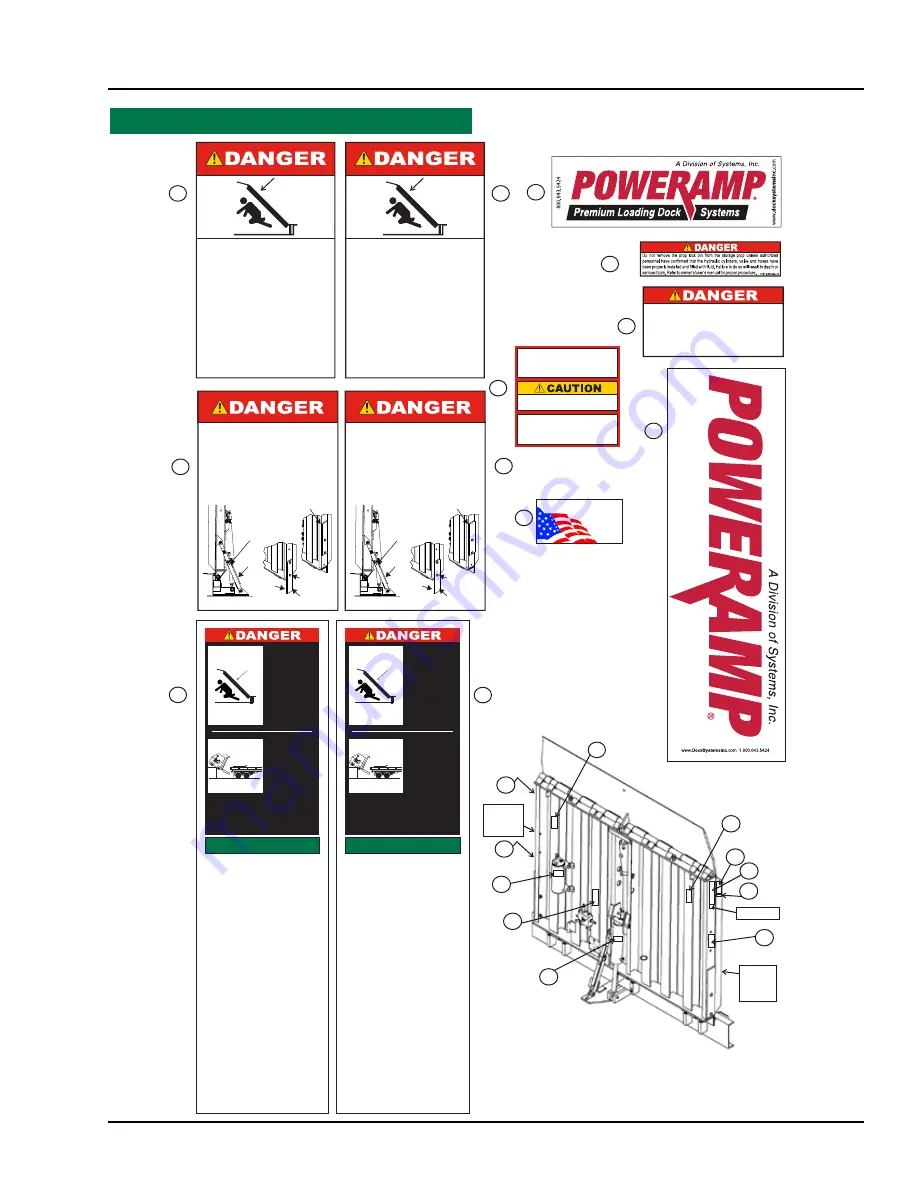

PRECAUTIONS

Precautionary Decal’s

2

3

4

5

6

1

1

2

7

8

4

2

2

5

7

6

1

3

VS

Se

rie

s

1

9

8

8

PROUDLY

MADE

IN

USA

SYSTEMS, INC.

GERMANTOWN, WI

MALVERN, AR

9

.

CRUSH HAZARD

Before doing any maintenance, repair or adjustments on the

dock leveler, first store the leveler in a vertical position with lip

extended, then ensure all maintenance props are in

maintenance positions and properly secured, and then

properly secure the storage prop with the prop lock pin.

DO NOT remove the prop lock pin from the storage prop until

you are sure the hydraulic system is in proper working condition

and all maintenance props are in maintenance positions and

properly secured. After prop lock pin is removed from the

storage prop all maintenance props may be returned to

storage positions. DO NOT stand in front of the dock leveler.

Reach from side of the leveler.

DO NOT force the prop lock pin out of the storage prop. If the

pin does not slide freely, support the leveler securely using other

means and determine the cause of the interference.

Failure to follow these instruction will result in death or serious

injury.

Refer to owner’s/user’s manual for proper procedure.

1751-0130 Rev D

.

CRUSH HAZARD

Before doing any maintenance, repair or adjustments on the

dock leveler, first store the leveler in a vertical position with lip

extended, then ensure all maintenance props are in

maintenance positions and properly secured, and then

properly secure the storage prop with the prop lock pin.

DO NOT remove the prop lock pin from the storage prop until

you are sure the hydraulic system is in proper working condition

and all maintenance props are in maintenance positions and

properly secured. After prop lock pin is removed from the

storage prop all maintenance props may be returned to

storage positions. DO NOT stand in front of the dock leveler.

Reach from side of the leveler.

DO NOT force the prop lock pin out of the storage prop. If the

pin does not slide freely, support the leveler securely using other

means and determine the cause of the interference.

Failure to follow these instruction will result in death or serious

injury.

Refer to owner’s/user’s manual for proper procedure.

1751-0130 Rev D

FIG.“A”

FIG.“B”

CRUSH HAZARD

DO NOT WORK UNDER OR IN FRONT OF DOCK

LEVELER

unless ALL props have been properly

positioned and secured. First position side

maintenance prop(s) and secure with screw and

nut as shown in figure “A” below. Then position

storage prop and secure with prop lock pin as

shown in figure “B” below. Failure to do so will result

in death or serious injury. Refer to owner’s/user’s

manual for proper procedure.

Prop Lock

Pin

Storage

Prop

Stored

Position

Maintenance

Position

Screw and Nut

Maintenance

Prop

1751-0230 Rev E

A

B

TOLERANCES

(UNLESS OTHERWISE NOTED)

FRACTIONAL:

1/32"

DECIMAL:

.00 =

.01"

.000 =

.005"

ANGULAR:

1

MATERIAL

DRAWN BY

CHECKED BY

DRAWING NO.

DATE

mikemartin

2/4/2015

vs prop

P O W E R A M P

M C G U I R E

D L M

S Y S T E M S, I N C.

L o a d i n g D o c k E q u i p m e n t

This print is the property of Systems, Inc. and represents a proprietary article in which Systems, Inc. retains any and all

patent and other rights, including exclusive rights of use and/or manufacture and/or sale. Possession of this print does

not convey any permission to reproduce, print or manufacture the article or articles shown therein, such permission to be

granted only by written authorization signed by an officer or other authorized agent of Systems, Inc. thereof.

STOCK NO.

FIG.“A”

FIG.“B”

CRUSH HAZARD

DO NOT WORK UNDER OR IN FRONT OF DOCK

LEVELER

unless ALL props have been properly

positioned and secured. First position side

maintenance prop(s) and secure with screw and

nut as shown in figure “A” below. Then position

storage prop and secure with prop lock pin as

shown in figure “B” below. Failure to do so will result

in death or serious injury. Refer to owner’s/user’s

manual for proper procedure.

Prop Lock

Pin

Storage

Prop

Stored

Position

Maintenance

Position

Screw and Nut

Maintenance

Prop

1751-0230 Rev E

A

B

TOLERANCES

(UNLESS OTHERWISE NOTED)

FRACTIONAL:

1/32"

DECIMAL:

.00 =

.01"

.000 =

.005"

ANGULAR:

1

MATERIAL

DRAWN BY

CHECKED BY

DRAWING NO.

DATE

mikemartin

2/4/2015

vs prop

P O W E R A M P

M C G U I R E

D L M

S Y S T E M S, I N C.

L o a d i n g D o c k E q u i p m e n t

This print is the property of Systems, Inc. and represents a proprietary article in which Systems, Inc. retains any and all

patent and other rights, including exclusive rights of use and/or manufacture and/or sale. Possession of this print does

not convey any permission to reproduce, print or manufacture the article or articles shown therein, such permission to be

granted only by written authorization signed by an officer or other authorized agent of Systems, Inc. thereof.

STOCK NO.

CRUSH HAZARD

DO NOT REMOVE

hydraulic cylinder until leveler is

safely supported by maintenance prop. Refer to

owner’s/user’s manual for proper maintenance

procedure. Failure to comply will result in death or

serious injury.

1751-0138 Rev B

ATTENTION INSTALLER:

Replace rear plug with

breather cap

Do not overfill

Oil should fill ½ site glass

Use ULTRA VIS HVI 15 or

MIL SPEC 5606

Questions Call: 800.643.5424

1751-0490 Rev B

Serial Tag

Left

Outside

Beam

Right

Outside

Beam

Decal 2 with have two positions, one on the left outside beam as shown and one on the right outside beam in the same position

Decal 8 will have two positions, one on the left outside beam as shown and one on the right outside beam in the same position

Decal 3 will be positioned on the upper most corner of the right outside beam (mirror position of decal 7)

CRUSH HAZARD

DO NOT WALK IN

FRONT OF DOCK

LEVELER until you:

Restore the dock

leveler to its safe

stored ver tical

position with lip

extended.

Unsupported dock

levelers can lower

unexpectedly.

Before allowing

vehicle to leave

the dock always:

Ensure that no equipment material or

people are on dock leveler.

Restore dock leveler to its safe stored

vertical position with lip extended.

OPERATION

1. Read and follow all instructions and warnings in the

owner’s/user’s manual.

2. Use of dock leveler restricted to authorized

personnel.

3. Always chock transport vehicle wheels or engage

vehicle restraint before operating dock leveler or

beginning to load or unload.

4. Never use hands or equipment to move the ramp or

lip.

5. Before activating dock leveler:

Ensure transport vehicle is backed in against

bumpers.

Remove any end loads if required.

Check transport vehicle alignment to avoid lip

interference. If lip does not lower to transport

vehicle bed, reposition transport vehicle.

6. Ensure that transport vehicle bed supports extended

lip or the leveler frame supports the ramp before

driving on ramp.

7. Stay clear of hinges and front and sides of moving

dock leveler.

8. Never use damaged or malfunctioning dock leveler.

Report problems immediately to supervisor.

MAINTENANCE/SERVICE

1. Read and follow all instructions, warnings and

maintenance schedules in the owner’s/user’s

manual.

2. Maintenance/service of dock leveler restricted to

authorized personnel.

3. Place barriers on the driveway and on dock floor to

indicate service work is being performed.

4. DO NOT SERVICE LEVELER unless dock leveler is

securely supported by all prop.

a. First, ensure all maintenance props are in

maintenance positions and properly secured.

b. Then engage prop lock pin in storage prop.

5. Turn off power and use OSHA lockout/tagout

procedures.

Failure to follow posted instructions

will result in death or serious injury.

Call 1.800.643.5424 for replacement placards, warning labels, or owner’s/user’smanuals

1751-0807 Rev C

SAFETY INFORMATION

CRUSH HAZARD

DO NOT WALK IN

FRONT OF DOCK

LEVELER until you:

Restore the dock

leveler to its safe

stored ver tical

position with lip

extended.

Unsupported dock

levelers can lower

unexpectedly.

Before allowing

vehicle to leave

the dock always:

Ensure that no equipment material or

people are on dock leveler.

Restore dock leveler to its safe stored

vertical position with lip extended.

OPERATION

1. Read and follow all instructions and warnings in the

owner’s/user’s manual.

2. Use of dock leveler restricted to authorized

personnel.

3. Always chock transport vehicle wheels or engage

vehicle restraint before operating dock leveler or

beginning to load or unload.

4. Never use hands or equipment to move the ramp or

lip.

5. Before activating dock leveler:

Ensure transport vehicle is backed in against

bumpers.

Remove any end loads if required.

Check transport vehicle alignment to avoid lip

interference. If lip does not lower to transport

vehicle bed, reposition transport vehicle.

6. Ensure that transport vehicle bed supports extended

lip or the leveler frame supports the ramp before

driving on ramp.

7. Stay clear of hinges and front and sides of moving

dock leveler.

8. Never use damaged or malfunctioning dock leveler.

Report problems immediately to supervisor.

MAINTENANCE/SERVICE

1. Read and follow all instructions, warnings and

maintenance schedules in the owner’s/user’s

manual.

2. Maintenance/service of dock leveler restricted to

authorized personnel.

3. Place barriers on the driveway and on dock floor to

indicate service work is being performed.

4. DO NOT SERVICE LEVELER unless dock leveler is

securely supported by all prop.

a. First, ensure all maintenance props are in

maintenance positions and properly secured.

b. Then engage prop lock pin in storage prop.

5. Turn off power and use OSHA lockout/tagout

procedures.

Failure to follow posted instructions

will result in death or serious injury.

Call 1.800.643.5424 for replacement placards, warning labels, or owner’s/user’smanuals

1751-0807 Rev C

SAFETY INFORMATION

Summary of Contents for VS series

Page 44: ...42 4111 0008 April 2017 June 2017 Centra Power Hydraulic Components PARTS A B E D F G I H C ...

Page 47: ...45 4111 0008 April 2017 June 2017 This page was left intentional left blank PARTS ...

Page 53: ...51 4111 0008 April 2017 June 2017 PARTS This page was left intentional left blank ...