Climate Control Duplex

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

1-888-769-7979 • www.powerexinc.com

IN558203AV 9/11

Description

The AD Series Powerex Duplex Air Compressors have been

designed, broken-in and tested to meet the most demanding

specifications for low oil carryover and long life in the

pneumatic climate control industry.

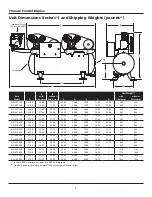

The units consist of two equally rated motor-compressor

assemblies mounted on a single ASME tank. The compressor

motors are NEMA Class B design. The AD Series Compressors

are ideal for instrumentation systems requiring an alternate

compressor for standby or overload capacity. See Table 1 for

motor sizes and air delivery capacities available.

Compressor assemblies are available with or without a factory

mounted basic or deluxe alternator/motor starter package. An

unloading feature is included on all compressors to provide

loadless starting. Models with an alternator are prewired and

ready for operation. Internal wiring allows for shutdown of

either compressor for repair while the other compressor is

running.

An alternating type operation is desirable for many reasons.

When a duplex air compressor is alternated, the temperature

of both units is kept above the ambient dew point to minimize

moisture deterioration and corrosion. Also, the reduction in

on-time provides a lower average head temperature with

reduced oil entrainment potential and improves the motor life

by holding down the average heat rise.

All units are run through a factory break-in and are tested

for air delivery, leakage and power consumption. Tank-

mounted units are shipped with a proper fill of compressor

oil in the crankcase and are furnished with an intake filter

with a replaceable cartridge. This filter is designed to remove

contaminates in the inlet air, as well as provide a quiet

operation.

All models have conveniently located oil drain and filler ports

to facilitate routine maintenance. Tanks have a condensate

drain valve with an extension for easy access. Mounting bases

are slotted to allow tension adjustments to aid in maintaining

proper compressor and motor alignment while adjusting

tension.

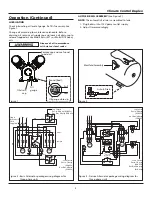

10

ON

8

6

TEST

20

30

5

40

OFF

0.5

0.5

45

2

4

10

sec.

min.

NOR

GREN

N

INLET

OUTLET

OUT

IN

100

0

PSI

60

20

40

PRESSURE GAGE

80

Specifications

Product

AD Series Powerex Duplex Air Compressors

Performance

Specifications

See Page 2

Lubrication

Splash Lubrication System (3/4 HP - 10 HP Models)

Operating

Voltages

1Ø

115 - 280 / 230 Volts, 60 Hz

3Ø

280 - 230 / 460 Volts, 60 Hz

Compression

Cycle

Single-Stage (3/4 HP - 10 HP Models)

Motor

Overload

Protection

1Ø

Built-in Thermal Overload (Standard)

3Ø

Magnetic Starter and Three Thermal

Overload Heaters (Optional)

Pressure

Settings

Lead

Cut-In: Factory Set at Approximately 70 psig (490 kPa)

Cut-Out: Factory Set at Approximately 90 psig (630 kPa)

Lag

Cut-In: Factory Set at Approximately 60 psig (420 kPa)

Cut-Out: Factory Set at Approximately 80 psig (560 kPa)

Overpressure

Protection

ASME Safety Valve Factory Set and Sealed at

Approximately 115 psig (805 kPa)

Outlet Air

Connections

3/4 inch NPT (30, 60, and 80 Gallon Tanks)

1 inch NPT (120 and 200 Gallon Tanks)

Tank Sizes

30 Gallon to 200 Gallon

California

Ordinance

462 (L) (2)

Meets Requirements of this Ordinance

Tank Isolation Standard All Units

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these

specifications, consult the local Powerex office. Powerex shall not be liable for damages resulting from misapplication or misuse of its products.