3

Climate Control Duplex

ON

TEST

OFF

2

0.5

4

6

sec.

8

10

5

0.5

45

20

30

10

40

min.

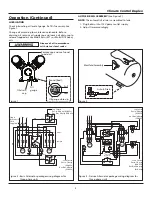

Figure 2

Manifold Assembly

Auto E-Drain

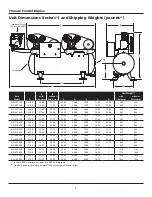

Figure 4 - Deluxe Alternator package wiring diagram for

three-phase units

AuTO E-DrAiN ASSEMBly

(See Figure 2)

NOTE:

The automatic E-drain is assembled to tank.

1. Plug E-drain into 115V power outlet supply.

2. Adjust times accordingly.

Operation (Continued)

luBriCATiON

Check lubricating oil level at gauge. Refill if necessary. See

Figure 1.

Change oil according to maintenance schedule. Before

draining oil, remove oil supply cap and loosen oil drain cap to

release trapped air. Use Mobil Rarus 427

®

or Mobil DTE heavy

oils.

Dispose of oil in accordance

with state or local codes.

Lead Switch

Cut In: 70 psig

(490 kPa)

Cut Out: 90 psig

(630 kPa)

Lag Switch

Cut In: 60 psig

(420 kPa)

Cut Out: 80 psig

(560 kPa)

L

1

L

2

L

3

IT

1

IT

2

IT

3

A1

A2

1M

Motor

1

Motor

2

2M

Selector

Switch

L

1

L

2

L

3

A1

A2

2T

1

2T

2

2T

3

X1

X2

FU

FU

FU

Alt

Figure 3 - Basic Alternator package wiring diagram for

three-phase units

L

1

Lag Switch

Cut In: 60 psig (420 kPa)

Cut Out: 80 psig (560 kPa)

L

2

L

3

Single

Disconnect

Field

Supplied

Motor

1

Motor

2

Re

d

Bl

ac

k

Bl

ue

Red

Red

Black

Blue

Alt L

Alt R

Alt

1M

2M

2M

A252

PS 2

PS 2

A251

Re

d

Re

d

2T

1

2T

2

2T

3

IT

1

IT

2

IT

3

L

1

L

2

L

3

Starter

Overload

PS 1

Alt C

A251

Lead Switch

Cut In: 70 psig

(490 kPa)

Cut Out: 90 psig

(630 kPa)

Figure 1

Remove cap and use funnel

to add oil

Oil drain

cap

Oil

gauge

Oil gauge close-up

Full

Low

Round (Red)