9

Oilless Reciprocating Air Compressor Pumps

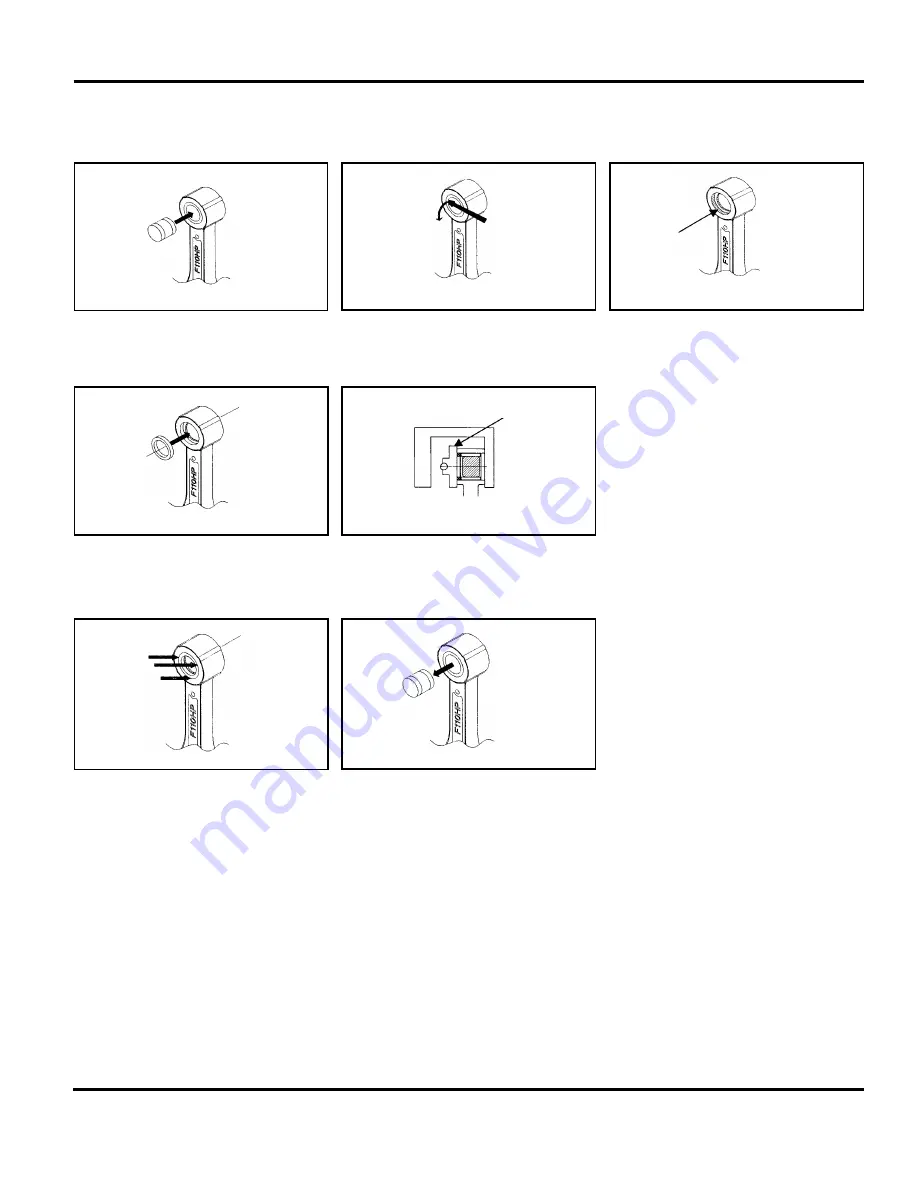

WRIST PIN BEARING SEAL REPLACEMENT (REPLACE EVERY 10,000 HOURS)

Replacing Oil Seal

1. Insert the plastic retention sleeve

which protects the needle bearing

from dropping out.

2. Remove the two oil seals by using a

screwdriver.

3. Clean both surfaces where oil seals

are removed.

4. Push the oil seal into the small bear-

ing end horizontally.

5. Press the oil seal with a C-clamp into

the small bearing end.

6. Repeat on opposite side.

7. Apply a small volume of adhesive at

several points.

8. Remove the retention sleeve inserted

at the first step.

Pushing

Board

Figure 16

Figure 21

Figure 20

Figure 19

Figure 18

Figure 17

Figure 22

NOTE:

You may use a “C” clamp or two large washers and bolt with nut through the bearing. Then apply pressure to install

the seals. This makes it easy to replace the seals without removing the crankshaft.