PMAC Air Compressor

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Description

Powerex

•

100 Mundy Memorial Drive

•

Mt. Juliet, TN 37122

•

USA

P 1.888.769.7979

•

F 513.367.3125

•

www.powerexinc.com

IN598601AV

•

01/2020

Page 1 of 12

General

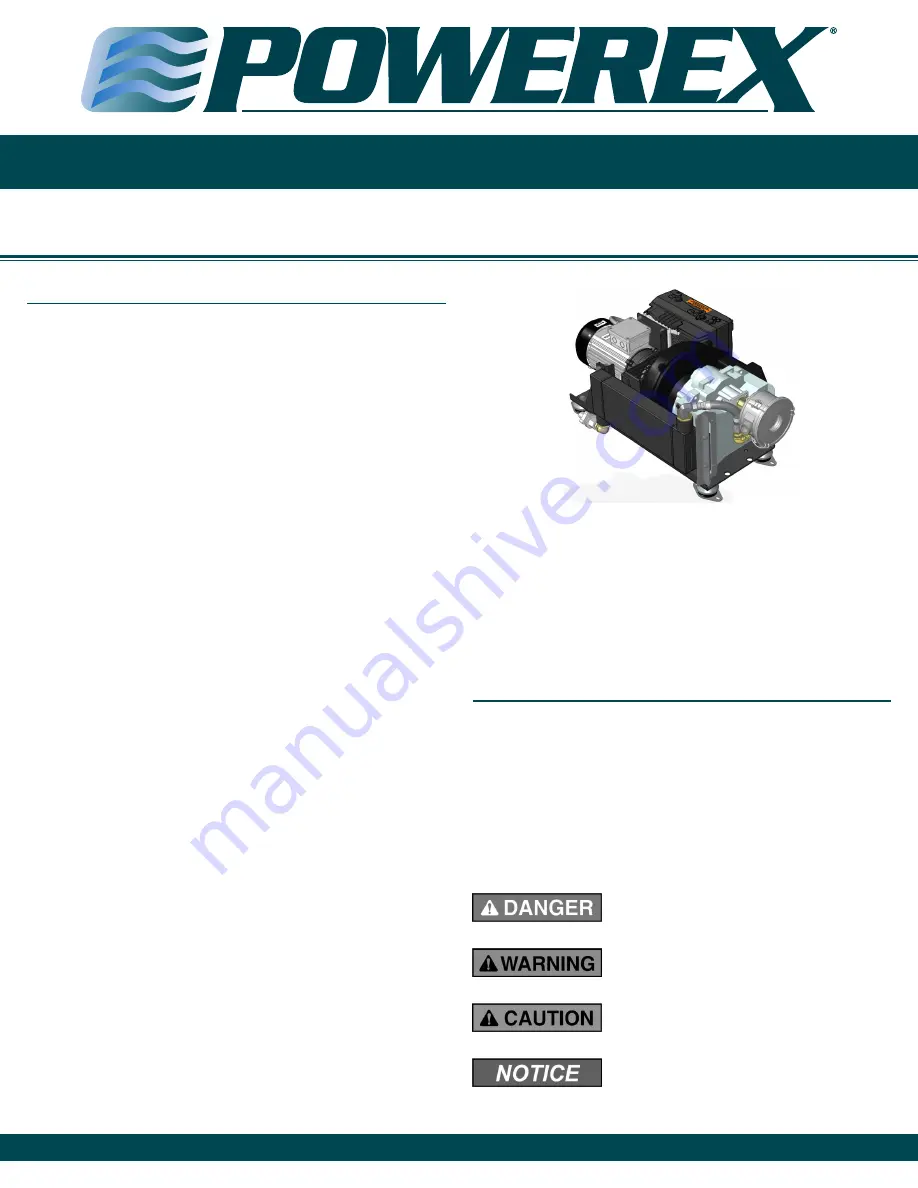

The Powerex Oil-less Rotary Scroll Air Compressor has advanced

scroll compressor technology through the development of a

completely oil-less unit. The Powerex Scroll Compressor offers a

dynamically balanced air end which insures vibration free operation.

No oil separation, oil filtration, or inlet valves are required on the

Powerex scroll unit.

Compression Cycle

The Powerex oil-less rotary scroll air compressor is based on the

theory of scroll compression. A scroll is a free standing, intricate

spiral bounded on one side by a solid, flat plane or base. A scroll set,

the basic compression element of a scroll compressor, is made up

of two identical spirals which form right and left hand parts. One of

these scroll components is indexed or phased 180° with respect to

the other so the scrolls can mesh. Crescent-shaped gas pockets are

formed and bounded by the spirals and the base plate of both scrolls.

As the moving scroll is orbited around the fixed scroll, the pockets

formed by the meshed scrolls follow the spiral toward the center

and diminish in size. The moving scroll is prevented from rotating

during this process so the 180° phase relationship of the scrolls is

maintained. The compressor’s inlet is at the outer boundary of the

scrolls. The compressed gas is discharged through the outlet at the

center of the fixed scroll so no valves are needed.

Tip Seal

The tip seal on the scroll compressor is self-lubricated and allows

the unit to operate efficiently without oil and expensive filtration.

Bearings

The bearings on the scroll compressor are regreaseable to allow

extended compressor life.

Intended Usage

This Powerex Oil-less Scroll set is intended for use as part of a system.

The compressor set provides compressed air from the oil-less scroll

pump when the electric motor is powered. The set includes the intake

air filter, pump, motor, coupling assembly, appropriate safety guards,

with the optional aftercooler, check valve, safety relief valve, and

inter connecting piping and tubing. Do not operate if the components

are missing and do not modify or remove any components without

approval from Powerex.

The Powerex module may be supplied with an intake filter installed

on the pump or the set may be intended for piping to a remote filter.

Always make sure that an inlet filter is in place and has a maximum

filtration of 2 micron and that the inlet air system is not restricted.

Operating the scroll pump with a restricted inlet will result in

pump damage. Do not modify or remove the Powerex check valve

or relief valve. The relief valve will open if the set is accidentally

operated with an isolation valve closed.

PMAC Air Compressor shown with optional aftercooler assembly

Safety Guidelines

A SEPARATE SAFETY BOOKLET IS PROVIDED ALONG WITH THIS

MANUAL. READ AND UNDERSTAND THE SAFETY BOOKLET. This manual

contains information that is very important to know and understand.

This information is provided for SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this information, observe the following

symbols. MAKE SURE EVERYONE OPERATING OR SERVICING THE

COMPRESSOR READS AND UNDERSTANDS ALL THE INFORMATION

PROVIDED. The operator must install equipment in a safe location and

is responsible for following all related local work safety requirements

and regulations.

Danger indicates an imminently hazardous

situation which, if not avoided, WILL result in

death or serious injury.

Warning indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

Caution indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or

moderate injury.

Notice indicates important information, that if not

followed, may cause damage to equipment.

NOTE:

Note indicates information that requires special attention.