PMAC Air Compressor

Powerex

•

100 Mundy Memorial Drive

•

Mt. Juliet, TN 37122

•

USA

P 1.888.769.7979

•

F 513.367.3125

•

www.powerexinc.com

IN598601AV

•

01/2020

Page 8 of 12

TOLERANCES NOT

SPECIFIED

DRAWINGS TO CONFORM TO CURRENT REVISION OF THE FOLLOWING ANSI

STANDARDS:

Y14.3 MULTI AND SECTIONAL VIEW DWGS

Y14.5 DIMENSIONING AND TOLERANCING

SYMBOL LEGEND

0.XX

u

0.XXX

u

g

u

SOLID EDGE

DRAWING

INCH

CONFIDENTIAL DISCLOSURE

This drawing is the property of POWEREX

of the SCOTT FETZER

COMPANY and is subject to return on demand.

Its contents are confidential and must not be

copied or submitted to

outside parties for use or examination.

SHEET 1 OF 1

1:4

SCALE

ORIGINATION DATE

APPROVALS ON FILE IN PLM

ITEM ID:

MATERIAL:

DESCRIPTION

150 PRODUCTION DRIVE, HARRISON OH 45030

(888) 769-7979

DO NOT SCALE DRAWING FOR

DIMENSIONS

DRAWING NUMBER

REVISION

D

SIZE

Error: No reference

--

.05

.005

1

REVISION NOTES

DESCRIPTION

ECN

PR/NOR

ENTER DESCRIPTION

PXECXXXX

XXXXXXXX

AUTHOR

apylant

6

8

10

11

1

12

5

2

3

4

7

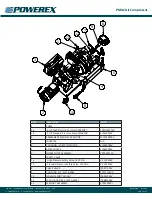

Item

Number

a2Production_Part_Num

ber

Project

Quantity

1

SDC016511AV

5HP SCROLL HP SDC

E-SERIES PUMP

1

2

SL500300AV

COUPLING, SDC, PMAC,

5HP

1

3

IP088200AV

SCROLL ADAPTER

PLATE GASKET

1

4

SL060000AV

DUPLICATE - USE

715638 INSTEAD

1

5

IP087700AV

SCROLL CHECK VALVE

(CV-157)

1

6

N/A

INVERTER, ABM, 5HP

WALL MOUNT.par

1

7

MC305000AV

MOTOR, PMAC, 5HP,

REMOTE MOUNT

1

8

IP639100AV

ISOLATOR FOOT

MOUNT PASCALEX BSB

60 135106

1

9

N/A

WELLNUT ASSEMBLY,

COMPRESSOR GREASE

PLUG, 1_4-20,

.031-.187

1

10

V-215900AV

SAFETY VALVE, 165PSI,

141 SCFM, 1/8" MNPT,

HIGH TEMP,

CONRADER

1

11

ST071515AV

COUPLING, 3/4" NPT,

BRASS

1

12

VP000501AV

3/4" INTAKE FILTER

1

9

Maintenance

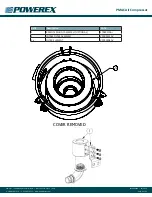

Coupling Element Replacement

The coupling element is designed to last for the life of the scroll

pump. If replacement does become necessary, remove the coupling

guard to gain access to the coupling rubber element (4). The photo

below shows the coupling guard separated from the assembly.

Before performing service, lock out and tag any

electric power source. Vent all air pressure from

the system and lock out and tag any other air sources.

Do not loosen the hexagon screws that secure the

motor adapter plate to the faceplate.

1. Loosen the screws that secure the coupling rubber element

radially to the drive hubs.

2.

DO NOT LOOSEN THE SETSCREW THAT SECURES THE DRIVE

HUB TO THE MOTOR SHAFT.

Do not use liquid thread lockers or adhesives. Do

not allow the element to become twisted while

tightening.

3.

Loosen the hex head screws that hold motor adapter plate 1

to motor adapter plate 2 (see image below). The motor must

be supported during this process to prevent damaging the

assembly. Pull the motor straight back to disengage.

6. Insert the Powerex supplied screws with pre-applied Inbus Plus

thread locker into the coupling element holes and tighten the

element securing screws to 37 ft-lbs.

4.

Now the axial bolts securing the rubber coupling element to

the compressor drive hub can be removed. Do not remove

or reposition the drive hubs.

Do not move or reposition the

motor mounting plate.

Installation is the reverse of removal.

Tightening torque for the bolts that secure the rubber coupling

element to the hubs is 37 ft-lbs.

5.

To install coupling insert, lightly lubricate the body and

underside of the element securing bolts with light oil or a clean

grease.

Do not lose the 4 alignment pins installed in the

two motor adapter plates. These pins are required

to maintain alignment between the motor and the pump.