2

Scroll Air Compressors Tankmount/Basemount

Installation

RECEIVING THE UNIT

Immediately upon receipt of the scroll

compressor, the unit should be inspect-

ed for any damage which may have

occurred in shipment. Any shipping

damage must be immediately filed with

the freight carrier.

The compressor nameplate should be

checked to see if the unit is the correct

model and voltage as ordered.

APPLICATION

When the scroll compressor is to be

used in applications other than the

compressing of atmospheric air, please

contact a Powerex representative for

engineering and warranty information

at 1-888-769-7979.

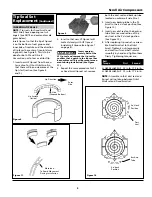

INSTALLATION SITE

1. The scroll compressor must be locat-

ed in a clean, well lit and well venti-

lated area.

2. The area should be free of excessive

dust, toxic or flammable gases, mois-

ture, water and direct sunlight.

3. Never install the compressor where

the ambient temperature is higher

than 104

o

F or where humidity is high.

4. Clearance must allow for safe, effec-

tive inspection and maintenance.

5. If necessary, use metal shims or leveling

pads to level the compressor. Never use

wood to shim the compressor.

VENTILATION

1. If the scroll compressor is located in a

totally enclosed room, an exhaust fan

with access to outside air must be

installed.

2. Never restrict the cooling fan

exhaust air.

3. Never locate the compressor where

hot exhaust air from other heat gen-

erating units may be pulled into the

unit.

WIRING

Refer to the general product manual.

All electrical hook-ups must be per-

formed by a qualified electrician.

Installations must be in accordance

with local and national electrical codes.

Use solderless terminals to connect the

electric power source.

PIPING

Refer to the general product manual.

1. Make sure the piping is lined up

without being strained or twisted

when assembling the piping for the

scroll compressor.

2. Appropriate expansion loops or

bends should be installed at the com-

pressor to avoid stresses caused by

changes in hot and cold conditions.

3. Piping supports should be anchored

separately from the compressor to

reduce noise and vibration.

4. Never use any piping smaller than

the compressor connection.

5. Use flexible hose to connect the out-

let of the compressor to the piping so

that the vibration of the compressor

does not transfer to the piping.

SAFETY VALVES

Tank mounted compressors are shipped

from the factory with safety valves

installed in the tank. The flow capacity

of the safety valve is equal to or greater

than the capacity of the compressor.

1. The pressure setting of the safety

valve must be no higher than the

maximum working pressure of the

tank.

2. Safety valves should be placed ahead

of any possible blockage point in the

system, i.e. shutoff valve.

3. Avoid connecting the safety valve

with any tubing or piping.

4. Manually operate the safety valve

every six months to avoid sticking or

freezing.

Operation

BEFORE START UP

1. Make sure all safety warnings, labels

and instructions have been read and

understood before continuing.

2. Remove any shipping materials,

brackets, etc.

3. Confirm that the electric power

source and ground have been firmly

connected.

4. Be sure all pressure connections are

tight.

5. Check to be certain all safety relief

valves, etc., are correctly installed.

6. Check that all fuses, circuit breakers,

etc., are the proper size.

7. Make sure the inlet filter is properly

installed.

8. Confirm that the drain valve is closed.

9. Visually check the rotation of the

compressor pump. If the rotation is

incorrect, have a qualified electrician

correct the motor wiring.

START-UP AND OPERATION

1. Follow all the procedures under

“Before start-up” before attempting

operation of the compressor.

2. Switch the electric source breaker on.

3. Open the tank discharge valve com-

pletely.

4. Check that the compressor operates

without excessive vibration, unusual

noises or leaks.

5. Close the discharge valve completely.

6. If the pressure does not rise on a

three phase unit, turn the unit off.

Have a qualified electrician switch

the breaker OFF and exchange the L1

and L2 connections (two out of three

phases of electric source) inside the

magnetic starter enclosure.

7. Check the discharge pressure. Also

make sure the air pressure rises to the

designated pressure setting by check-

ing the discharge pressure gauge.

8. Check the operation of the pressure

switch by opening the tank outlet

valve and confirming the compressor

starts as pressure drops.

Minimum Clearances

Above

24”

Drive belt side

12”

Other sides

20”