16

Scroll Enclosure Air Compressors

Scheduled Maintenance

Per OSHA regulations, lockout

compressor system from all

power sources BEFORE performing any maintenance.

INTAKE FILTER

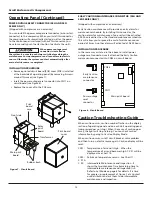

1. Remove the front panel of the unit.

2. Remove the air inlet housing, the wing nut and the inlet

fi lter element.

3. Clean the inlet fi lter element with compressed air or

replace with a new element.

NOTE:

Never clean fi lter element with solvents or water.

VENTILATION SCREEN

1. Remove

the ventilation screen located at the rear of the unit.

2. Clean with compressed air or soap and water, if necessary.

INSPECT V-BELT TENSION

1. Check V-Belt tension with tension gauge.

2. Adjust to the specifi cations listed in Chart 15.

GREASE COMPRESSOR BEARINGS

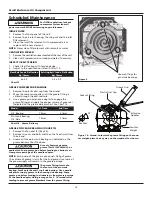

1. Remove the plastic dust cap from the airend.

2. Move the compressor pulley until the grease fi tting is

visible through the dust cap hole.

3. Use a grease gun extension adapter to engage the

grease fi tting and supply the proper volume of grease as

indicated on the grease delivery chart. See Chart 16.

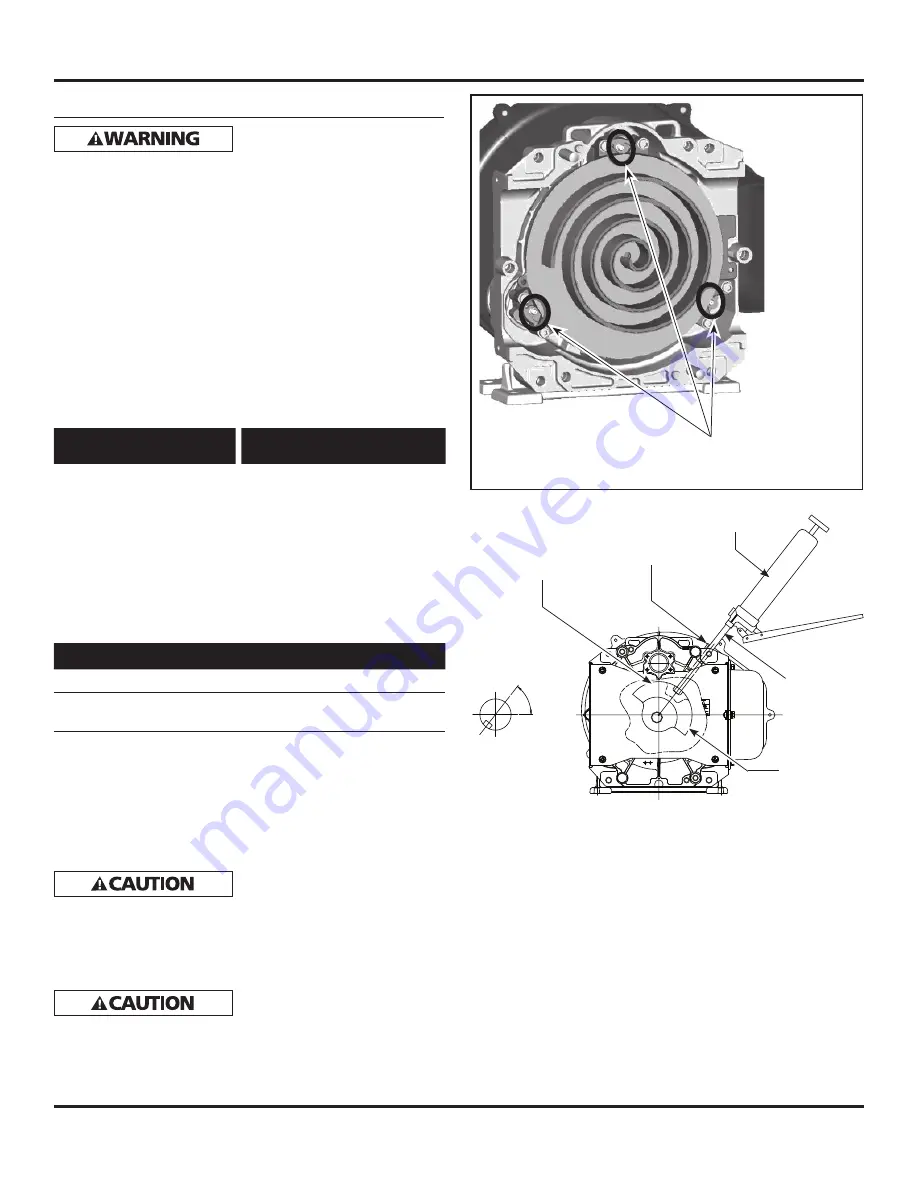

GREASE PIN CRANK BEARING (FIGURE 10)

1. Remove the fan duct (2) (Key #6).

2. Remove the nuts and bolts and then the fi xed scroll from

the air end.

3. Grease all three pin crank bearings as indicated on the

grease delivery Chart 14 above.

Use only Powerex genuine

grease (Part # IP600000AV), or

equivalent. Pump grease gun before feeding to eliminate air

from grease passage of the needle adapter.

NOTE:

Each pump of the grease gun equals 0.65g of grease.

The volume of grease is less after the 2nd pump since some of

the grease supply will remain in the grease passage.

The grease fi tting, located in

the center of the pin crank

bearing, feeds only the orbit scroll side bearing. Use a needle

adapter to supply grease to the housing side bearing. Pump

grease gun before feeding to eliminate air from grease passage

of the needle adapter. Hold grease gun for 5 - 10 seconds after

feeding to prevent grease blowback from the grease fi tting.

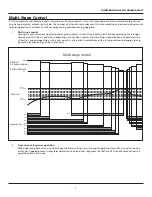

New Belt Load ± Defl ection

Kg/ 10mm

Existing Belt Load ± Defl ection

Kg/ 10mm

6 ± 0.5

5.5 ± 0.5

Chart 15

Model

1st Time

2nd Time

O.S. Bearing

7 times

6 times

Pin Crank Bearing

O.S. Side

7 times

7 times

Chart 16 - Grease Delivery

Figure 10 - Airend: to locate the grease fi tting on the coun-

ter weight, place the key way on the crankshaft as shown.

Key Way

Counter

Weight

Extension

Adapter

Grease Gun

Plastic Dust Cap

Grease Fitting

52°

Grease fi ttings for

pin crank bearings

Figure 9