4

Scroll Enclosure Air Compressors

General Safety Information

(Continued)

15. Always provide a clean air source for your compressor.

Keep all piping direct and short when using an outside

air source.

16. Locate compressor inlet system away from possible

ingestion of fl ammable or toxic vapors, water, dirty air or

air temperatures exceeding 104°F.

17. Never set the pressure to a higher setting than the one

provided from the factory.

18. Check all gauges daily to be sure the compressor is

operating correctly.

19 Follow all directions for maintenance. Check all safety

devices according to instructions.

20. Never attempt to lift or move the compressor except

when using the proper lifting procedures.

21. Make sure all electrical components follow the National

Electric code and all state and local codes when installing

the compressor.

22 Do not operate the compressor if unusual noise or

vibration occurs.

23. Keep all panels in place at all times.

24. Standard motors are not appropriate for dirty, wet or

explosive areas.

25. All service should be performed by trained and qualifi ed

people only.

26. The Drive Belt tension should be checked often during

initial operation of the compressor.

27. Never substitute oil bath or oil wetted fi lters for the inlet

fi lters provided with the compressor.

Installation

INSTALLATION SITE

1. The scroll compressor must be located in a clean, well lit

and well ventilated area. A contaminated area can clog

the intake fi lter and / or intake metal mesh.

2. The area should be free of excessive dust, toxic or

fl ammable gases, moisture and direct sunlight.

3. Never install the compressor where the ambient

temperature is higher than 104°F or lower than 32°F

or where humidity is high. High humidity will cause

electrical short circuit and rusting of components.

4. Clearance must allow for safe, effective inspection and

maintenance. 24 inch of clearance for sides, 40 inch

clearance from the top is recommended.

5. If necessary, use metal shims or leveling pads to level the

compressor. Never use wood to shim the compressor.

VENTILATION

1. If the scroll compressor is located in a totally enclosed

room, an exhaust fan with access to outside air must be

installed.

2. Never restrict the cooling fan exhaust air.

3. Vent the exhaust air outside to prevent the compressor

from operating at high temperatures and shutting down.

4. Never locate the compressor where hot exhaust air from

other heat generating units may be pulled into the unit.

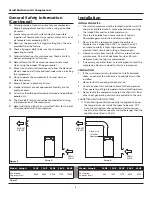

SUGGESTED VENTILATION SYSTEM

1) The following ventilation capacity is designed to keep

the temperature rise inside the room to be max. 10°F.

Since the calculation is based on zero static pressure,

the actual ventilation capacity should be larger than the

capacity value listed in Chart 1.

FRESH

AIR IN

EXHAUST

AIR OUT

FRESH

AIR IN

EXHAUST

AIR OUT

8 inches to

12 inches

Clearance

Setup A

Setup B

Figure 3

Model - Setup B

10 HP

15 HP

20 HP

30 HP

40 HP

Ventilation

Capacity (cfm)

885

1415

1770

2830

3535

Model - Setup A

10 HP

15 HP

20 HP

30 HP

40 HP

Ventilation

Capacity (cfm)

2650

3885

5300

7770

10595

Chart 1