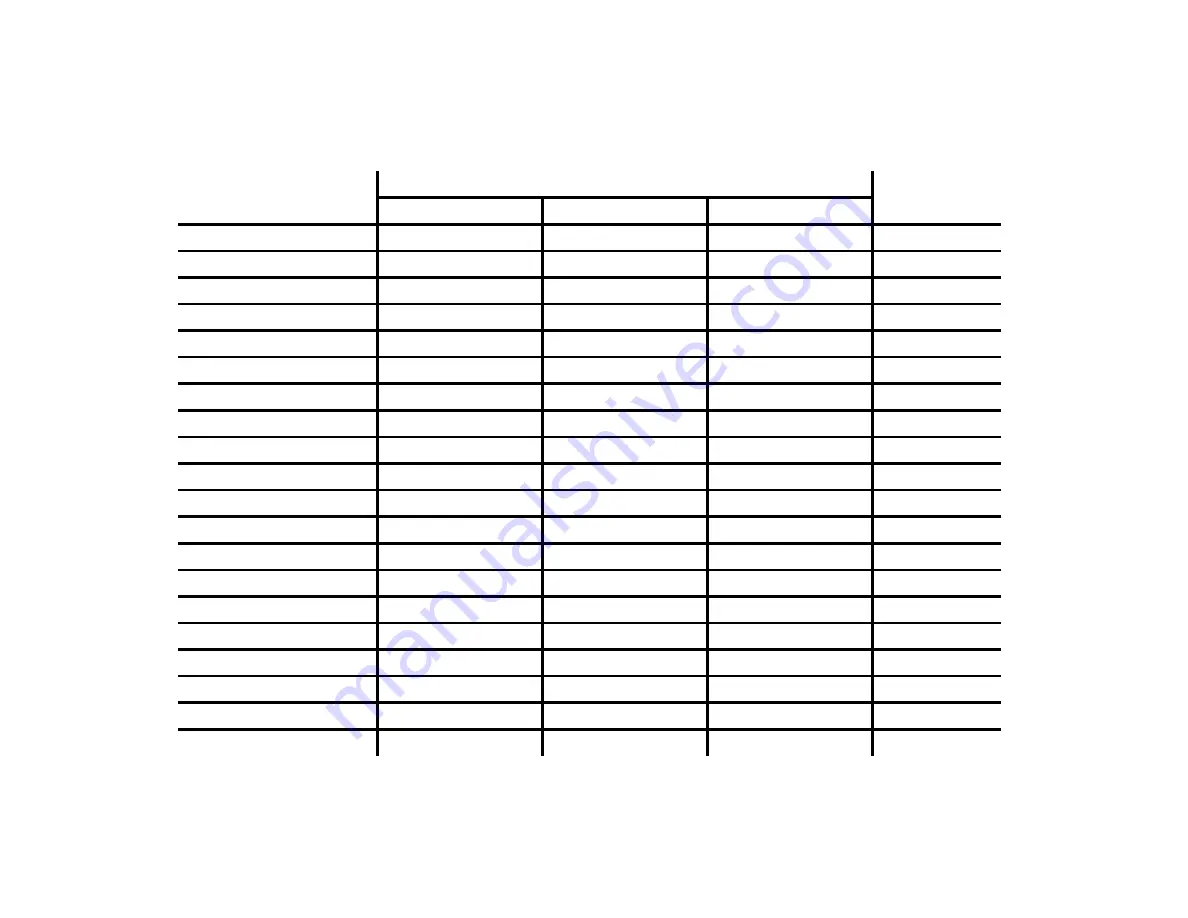

35

SLAE03E

SLAE05E

SLAE05EHP

Air end pulley

92843051

92549110

92549110

1

Key

IP600600AV

IP600600AV

IP600600AV

1

Centrifugal fan

IP601300AV

IP601300AV

IP601300AV

1

Fan Duct (1)

IP601400AV

IP601400AV

IP601400AV

1

Fan Duct (2)

IP601500AV

92519042

92519042

1

Fan Cover

IP601700AV

IP601700AV

IP601700AV

1

Fan Duct Gasket (1)

IP601800AV

IP601800AV

IP601800AV

1

Heat Insulation Pipe

IP602000AV

IP602000AV

IP602000AV

1

Fan Duct Gasket (2)

IP602400AV

IP602400AV

IP602400AV

1

Long Nipple

96647011

96647011

96647011

1

Dust Cap

IP603500AV

IP603500AV

IP603500AV

1

Tip Seal Set

92834090

92832070

92832080

1

Filter Assembly

ST073922AV

ST073922AV

ST073922AV

1

Filter Element

91348550

91348550

91348550

1

Street Elbow

RB90SF34

RB90SF34

RB90SF34

1

Adaptor Plate

IP086100AV

IP086100AV

IP086100AV

1

Intake Gasket

IP088200AV

IP088200AV

IP088200AV

1

Grease Gun Kit

IP616200AJ

IP616200AJ

IP616200AJ

1

Grease Gun

IP616100AJ

IP616100AJ

IP616100AJ

1

Grease (80g)

IP600000AV

IP600000AV

IP600000AV

1

Parts number for models

Description

Quantity

Summary of Contents for SLAE03E

Page 1: ...Scroll Compressor Service and Maintenance Manual ...

Page 4: ...4 INTAKE AIR FILTER REPLACEMENT every 2 500 HOURS MAINTENANCE 1 Remove the Filter Cover ...

Page 6: ...6 3 Reassemble the Filter Cover ...

Page 8: ...8 2 Clean FS fins with a blow gun ...

Page 9: ...9 3 Reassemble the FS cover ...

Page 11: ...11 2 Blow off dirt and dust ...

Page 12: ...12 FAN DUCT CLEANING 5 000 HOURS MAINTENANCE Wipe out dirt and dust ...

Page 17: ...17 v Put the removed Plastic Dust Cap back ...

Page 18: ...18 2 PIN CRANK BEARINGS i Remove the Fan Duct 2 Remove these three bolts ...

Page 24: ...24 2 REPLACEMENT i Remove the fan duct 2 Remove these bolts ...

Page 27: ...27 iv Remove dust from both OS and FS plates with clean cloth or air ...

Page 30: ...30 vii Insert LP Tip Seal all the way and cut excessive material ...

Page 31: ...31 viii Repeat the same procedure for FS Tip Seal set ...

Page 34: ...34 PARTS LIST ...