5

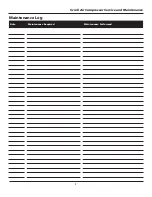

Item

Action needed

Operating Hours

Remarks

500

2500

5000

10,000

15,000

20,000

Inlet Air Filter

Clean, replace

●

▲

(Every 2,500 hrs or less)

Blower Fan

Clean

●

●

●

●

Fan Duct

Clean

●

●

●

●

Compressor Fins

Clean

●

(Every 2,500 hrs or less)

Bearings

Regrease

▲

▲

Service Center Only

(Every 5,000 hours for

145 psig scroll)

Tip Seal Set

Replace

▲

▲

(Every 5,000 hours for

145 psig scroll)

Heat Insulation

Pipe

Replace

▲

▲

(Every 5,000 hours for

145 psig scroll)

●

Clean

▲

Replace, regrease

NOTES:

1. Inspect and perform maintenance periodically according to maintenance schedule.

2. The maintenance schedule relates to the normal operating conditions. If the circumstances and load condition are

adverse, shorten the cycle time and do maintenance accordingly.

MAINTENANCE SCHEDULE

GREASE DELIVERY

SLAE03EB

SLAE05E

SLAE05EHP

Bearing

1st Time

2nd Time

1st Time 2nd Time

1st Time

2nd Time

Orbit Scroll Bearing

5 Times

4 Times

7 Times

6 Times

7 Times

6 Times

Pin Crank Bearing Orbit Scroll Side

4 Times

4 Times

5 Times

5 Times

7 Times

7 Times

Pin Crank Bearing Housing Side

Do Not Have to Grease

Do Not Have to Grease

Do Not Have to Grease

NOTE:

Each pump of the grease gun equals 0.65 grams of grease.

Scroll Air Compressor Service and Maintenance