14

4.3 PUMP LUBRICANT

1. Oil Level

Always operate the unit in a level position. Prior to start-up, check the sight glass to ensure the oil in

the pump is at the required level. If the oil level is too low, remove the oil fill plug and

add oil until the

level is at the center of the sight glass

. For approximate oil requirements, see pages 16-17. Do not

overfill or under fill as it could damage the pump.

CAUTION!

The oil level in the pump crankcase

must be checked daily

.

2. Oil Type

The correct lubricant is essential to the proper operation of your compressor. For single stage or 2-

stage compressors, use

ISO 68, SAE 25 weight oil

. This compressor oil is available at your local

Princess Auto store.

CAUTION!

Do not use motor oil in the compressor pump

.

3. Condensation

Water condensing in the crankcase can occur under certain humid conditions or light duty cycling.

This water must be removed from the pump to prevent damage. Drain the oil and refill.

Condensation can be prevented by allowing the pump to reach its normal operating temperature by

releasing air from the tank and allowing the pump to run, or by using more air, which will cause the

pump to operate more frequently.

CAUTION!

A rise in the oil level and a milky color indicates that

condensation is forming in the crankcase

. This condensation must be drained immediately or the

pump may be damaged.

4.4 PULLEY ALIGNMENT & BELT TENSION

Improper pulley alignment and belt tension are causes for motor overloading, excessive vibration and

premature belt or bearing failure. To prevent this from happening, check the pulley alignment and belt tension

on a regular basis.

Periodically, inspect both the motor and compressor pulleys for oil, grease, nicks or burrs. Clean or replace

pulleys if necessary. Make sure the pulleys are securely fastened. Align the compressor pulley with motor.

The drive belt grooves of both pulleys should be in line with each other. The compressor crankshaft must be

parallel to the motor shaft.

WARNING!

To avoid personal injury, always shut off main power disconnects for the compressor and

relieve all air pressure from the system before performing any service on the air compressor

.

1. Belt Tension

Proper belt tension and pulley alignment must be maintained for maximum drive efficiency and belt

life. The correct tension exists if a deflection (see A in Figure 3 on the next page) of ½” (13 mm)

occurs by placing 10 lb (4.4 kg) of force (see B in Figure 3 on the next page) midway between the

motor pulley and the pump flywheel. This deflection can be adjusted by the following procedure. The

pulley should be carefully aligned with the flywheel and all setscrews should be kept tight.

Summary of Contents for 10E-2-120H-1-230

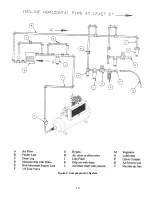

Page 10: ...10 Figure 2 Compressor Air System...

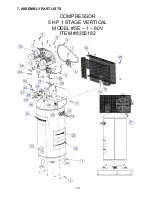

Page 20: ...20 7 ASSEMBLY PART LISTS COMPRESSOR 5 HP 1 STAGE VERTICAL MODEL 5E 1 60V ITEM 8355182...

Page 22: ...22 COMPRESSOR 5 HP 2 STAGE VERTICAL MODEL 5E 2 80V ITEM 8346645...

Page 24: ...24 COMPRESSOR 10 HP 2 STAGE HORIZONTAL MODEL 10E 2 120H 3 230 ITEM 8346652...

Page 26: ...26 COMPRESSOR 10 HP 2 STAGE HORIZONTAL MODEL 10E 2 120H 1 230 ITEM 8347767...

Page 28: ...28 COMPRESSOR 10 HP 2 STAGE HORIZONTAL MODEL 10E 2 120H 3 575 ITEM 8347783...

Page 30: ...30 8 PUMP PART LISTS PUMP 10001977 LPW6548ALHI USED ON ITEM 8355182...

Page 31: ...31 PUMP 10001977 LPW6548ALHI USED ON ITEM 8355182...

Page 32: ...32 PUMP 10002222 LP205CT USED ON ITEMS 8346645...

Page 33: ...33 PUMP 10002222 LP205CT USED ON ITEMS 8346645...

Page 34: ...34 PUMP 10002332 LP210CT USED ON ITEMS 8346652 8347767 8347783...

Page 35: ...35 PUMP 10002332 LP210CT USED ON ITEMS 8346652 8347767 8347783...