5

2. SAFETY GUIDELINES

DEFINITIONS

Safety symbols identify important safety messages that alert to the possibility of personal injury or death.

Review them carefully before operating the unit and before performing maintenance or repairs. Check the rules

and regulations at your location and identify possible hazards. The appropriate signal word for each message

has been selected using the following guidelines:

-

Danger indicates an immediate and specific hazard, which

will

result in

severe

personal

injury

or

death

if the proper precautions are not taken.

-

Warning indicates a specific hazard or unsafe practice, which

could

result in

severe

personal injury

or

death

if proper precautions are not taken.

- Caution indicates a potentially hazardous situation, which

may

result in

minor

or

moderate

injury

if proper practices are not taken.

____________________________________________________________________________

IMPORTANT SAFETY INSTRUCTIONS

Read and understand the operator’s manual and all safety alerts before

operating or maintaining your Compressor. Be certain that everyone operating this

equipment is familiar with the recommended operating and maintenance procedures

and follows all the safety precautions. Never let children or untrained adults operate

the machine.

_______________________________________________________________________________

RISK OF FIRE OR EXPLOSION

Never spray flammable liquids in a confined area. It is normal for the motor and pressure switch to produce

sparks while operating. If sparks come into contact with vapors from gasoline or other flammable solvents,

they may ignite, causing a fire or an explosion. Always operate the compressor in a well-ventilated area as far

from spray area as possible.

RISK OF BURSTING

Air under pressure will cause injury, death or property damage. Do not exceed pressure rating. Safety relief

valve settings must not be changed, check regularly for proper operation. Do not weld, drill or modify

compressor tank; it can severely impair tank strength and cause extremely hazardous conditions. Any

adjustment by user will void the warranty.

RISK OF INJURY

Do not operate with belt guard removed. Wait for all moving parts to stop before removing belt guard for

compressor servicing. Belt guard must be fastened in place before starting the compressor.

RISK OF ELECTRICAL SHOCK

All electrical enclosures, cables, wiring and components must be installed and grounded in accordance with

national and local electrical code.

ALL WIRING MUST BE DONE BY A LICENSED ELECTRICIAN.

Failure to comply could result

in personal injury or damaged components.

Summary of Contents for 10E-2-120H-1-230

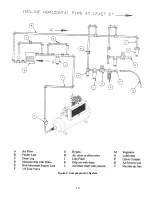

Page 10: ...10 Figure 2 Compressor Air System...

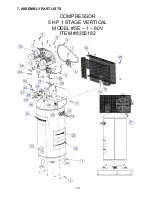

Page 20: ...20 7 ASSEMBLY PART LISTS COMPRESSOR 5 HP 1 STAGE VERTICAL MODEL 5E 1 60V ITEM 8355182...

Page 22: ...22 COMPRESSOR 5 HP 2 STAGE VERTICAL MODEL 5E 2 80V ITEM 8346645...

Page 24: ...24 COMPRESSOR 10 HP 2 STAGE HORIZONTAL MODEL 10E 2 120H 3 230 ITEM 8346652...

Page 26: ...26 COMPRESSOR 10 HP 2 STAGE HORIZONTAL MODEL 10E 2 120H 1 230 ITEM 8347767...

Page 28: ...28 COMPRESSOR 10 HP 2 STAGE HORIZONTAL MODEL 10E 2 120H 3 575 ITEM 8347783...

Page 30: ...30 8 PUMP PART LISTS PUMP 10001977 LPW6548ALHI USED ON ITEM 8355182...

Page 31: ...31 PUMP 10001977 LPW6548ALHI USED ON ITEM 8355182...

Page 32: ...32 PUMP 10002222 LP205CT USED ON ITEMS 8346645...

Page 33: ...33 PUMP 10002222 LP205CT USED ON ITEMS 8346645...

Page 34: ...34 PUMP 10002332 LP210CT USED ON ITEMS 8346652 8347767 8347783...

Page 35: ...35 PUMP 10002332 LP210CT USED ON ITEMS 8346652 8347767 8347783...