3-1/2", 28° Framing Nailer

6

For technical questions call: 1-800-665-8685

8314106

V 2.0

AIR SOURCE INSTALLATION

1. Set the air pressure regulator on the air compressor to 90 PSI. Do not exceed the tool’s recommended air

pressure. Excess pressure could result in damage to the tool, to your work piece or serious injury.

2. Prepare a standard 1/4” air connector for use with your tool. Wrap the threaded portion of the air connector

with thread tape. Attach it to the tool’s air inlet. Tighten securely.

3. Attach a standard quick connector to the air source’s hose. Attach the air hose to the tool.

Note: If you are not using an in-line oiler, add a few drops of air tool oil in the tool’s air inlet before use. In

the same manner, add a few drops after every hour of use.

4. Check the air line and its connections for air leaks. Do not use this tool until you have repaired all air leaks.

Note: Turn off the air compressor, disconnect the air pressure hose and discharge any residual pressure

inside the tool before changing accessories or making any adjustments to the tool. Failure to do so could

result in severe injury, tool or property damage.

LUBRICATION

WARNING! USE ONLY THE AIR TOOL LUBRICANTS SUPPLIED WITH THE TOOL. Do not use other lubricants as

they may damage the tool.

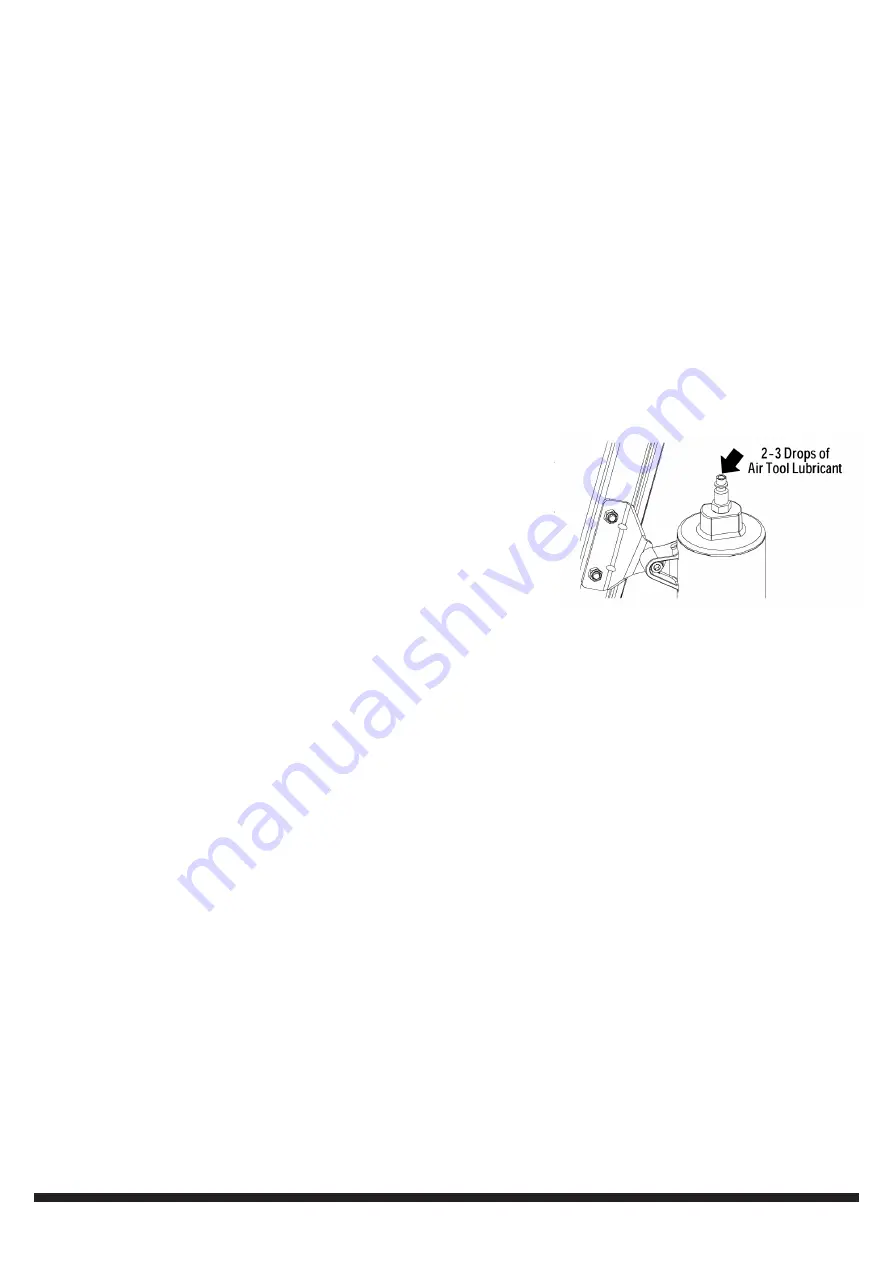

If the tool is not used with an in-line lubrication system on the air supply

it is necessary to periodically lubricate the tool with air tool lubrication.

Under low use, lubricate once a day. Under heavy use, lubricate twice a

day. To lubricate, insert 2-3 drops of lubricant into the air supply fitting

attached to the tool handle (FIG 13). Using too much oil will cause it to

collect in the tool and be noticeable in the exhaust.

Do not use detergent oil, WD-40, transmission fluid, motor oil, or other

lubricants not specifically designated as air tool lubricants. These lubricants will cause accelerated wear to the seals,

O-rings, and bumpers in the tool, resulting in poor tool performance and frequent maintenance.

UNPACKING

1. Carefully remove the parts and accessories from the box.

2. Make sure that all items listed in the parts lists are included.

3. Inspect the parts carefully to make sure the tool was not damaged while shipping.

4. Do not discard the packaging material until you have carefully inspected and satisfactorily operated the tool.

WARNING! If any part is missing, do not operate the tool until the missing parts are replaced. Failure to do so

could result in serious personal injury.

Summary of Contents for 8314106

Page 2: ......

Page 15: ...3 1 2 28 Framing Nailer 15 For technical questions call 1 800 665 8685 8314106 V 2 0...

Page 16: ......

Page 18: ......