Operator's Manual

4-Cycle Cultivator

866-443-2576

12

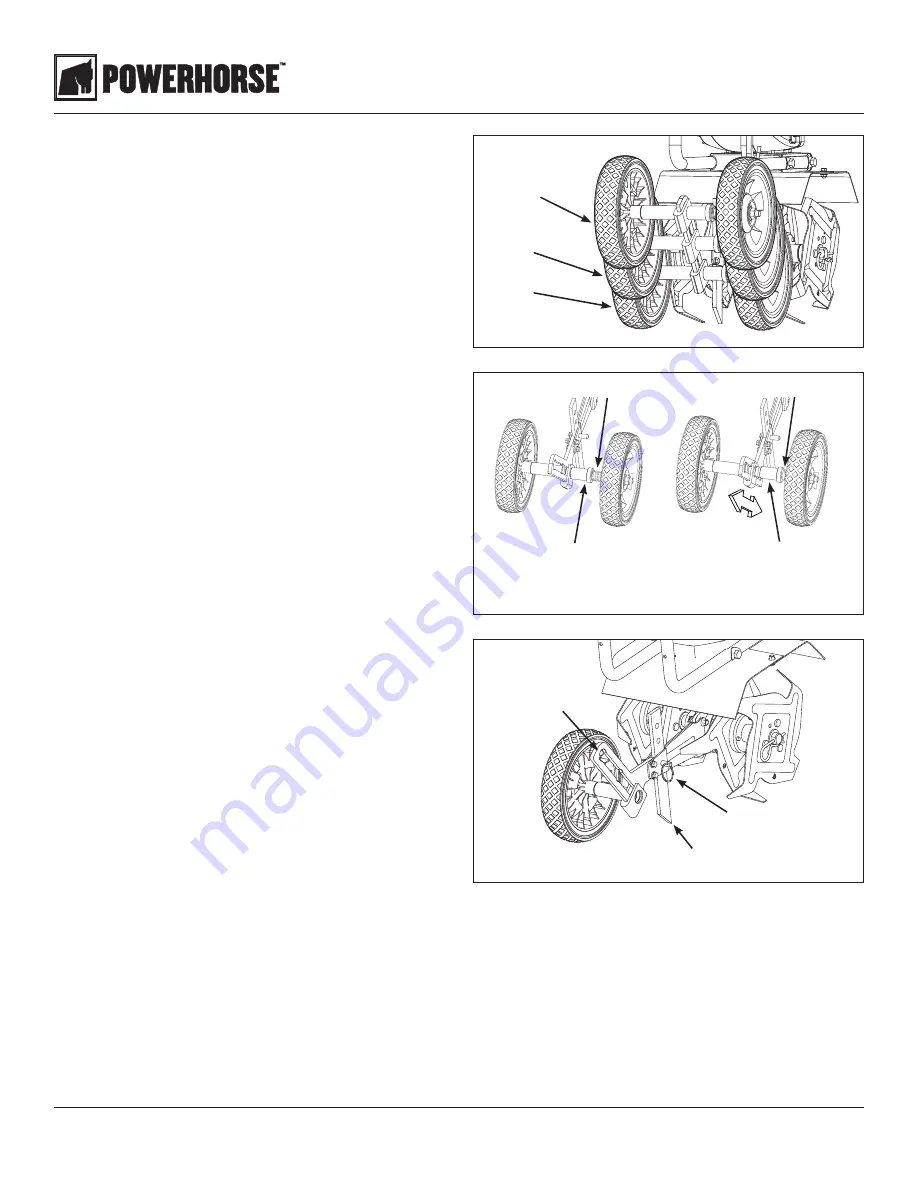

ADJUSTING WHEELS AND DRAG STAKE

The wheels on the cultivator can be adjusted to one of three

positions. The LOW wheel position is used for transporting the

cultivator across a smooth level surface while the engine is not

running. The HIGH and HIGHEST wheel positions are used when

cultivating in soil and help stabilize the unit when cultivating at

different depths. (SEE FIGURE 5)

To adjust wheels up or down (SEE FIGURES 6 AND 7):

1. Pull the locking metal sleeve against the spring, away from the

vertical guide until it releases from one of the three notched

positions in the vertical guide.

2. Slide the wheel set up or down to the desired position, and

release the locking metal sleeve until it locks into desired

notch in the vertical guide.

The drag stake is used to help regulate cultivating depth and

control the cultivator from leaping forward during operation.

Resistance to forward motion is greatest when the drag stake is

set in its lowest position allowing for deeper cultivation.

To adjust the drag stake (SEE FIGURE 7):

1. Pull the pin out of the drag stake mount hole.

2. Position the drag stake so the pointed tip is directed

downward.

3. Insert the pin into the hole that achieves desired depth.

FIGURE 5

HIGHEST position

HIGH position

LOW position

drag stake

vertical guide

detent pin

locking metal sleeve

(LOCKED position)

expanded spring

FIGURE 7

compressed spring

FIGURE 6

locking metal sleeve

(UNLOCKED position)

TINE REMOVAL AND INSTALLATION

To Remove Tines (SEE FIGURE 8)

1. Remove the hairpins from each end of the tine shaft.

2. Slide the four tines off the shaft.

To Install Tines

1. First slide the inside tines onto each end of the tine shaft.

One inside tine is stamped with a B and the other is

stamped with a C.

2. Slide the outside tine A and tine D onto each end of the

shaft next. The tines should be installed in the correct order

so that they are positioned left to right A, B, C, D, as viewed

from the user’s position on the cultivator. Make sure that

the hub collars on both the right and left pairs of tines face

each other so that there is adequate spacing between the

tine blades. SEE FIGURE 8

3. Insert the hairpins into the holes at each end of the tine

shaft to lock the tines into place.

NOTE: Tines can be reversed so the pointed tip of the tines

are directed forward - for more aggressive digging. In this

arrangement, tines are positioned left to right D, C, B, A as

viewed from the user’s position