9

POWERJET 260 PRO Injector Cleaner & Tester

5.7

On-Vehicle Cleaning

After the motorcycle engine has been in operation for a period of time, its fuel flow may be blocked or become un-smooth

owing to buildup of dust and impurities in fuel channel. In addition, the carbon deposits and gum made by combustion can

easily adhere to the injectors, inlet and outlet ports, inlet and outlet hoses, throttle and combustion chamber. So the fuel

supply system, combustion chamber and injector of the engine must be cleaned on a timely basis. Combustion Chamber

cleaning is a solution that can save your time and labor.

Procedures:

1)

Please check if there is test liquid or detergent inside the fuel tank before on-vehicle cleaning. If test liquid is in the

tank, replace it with detergent.

2)

Blend the detergent with the fuel at a certain ratio, and fill the mixture into the fuel tank.

3)

The connection of engine fuel pipes has been shown in “Connecting” below.

4)

Select

On-Vehicle Cleaning

function, and set the cleaning time.

5)

Press

Run

key to start the function, adjust the fuel pressure by pressing

+

or

–

keys.

6)

Start the engine to begin cleaning.

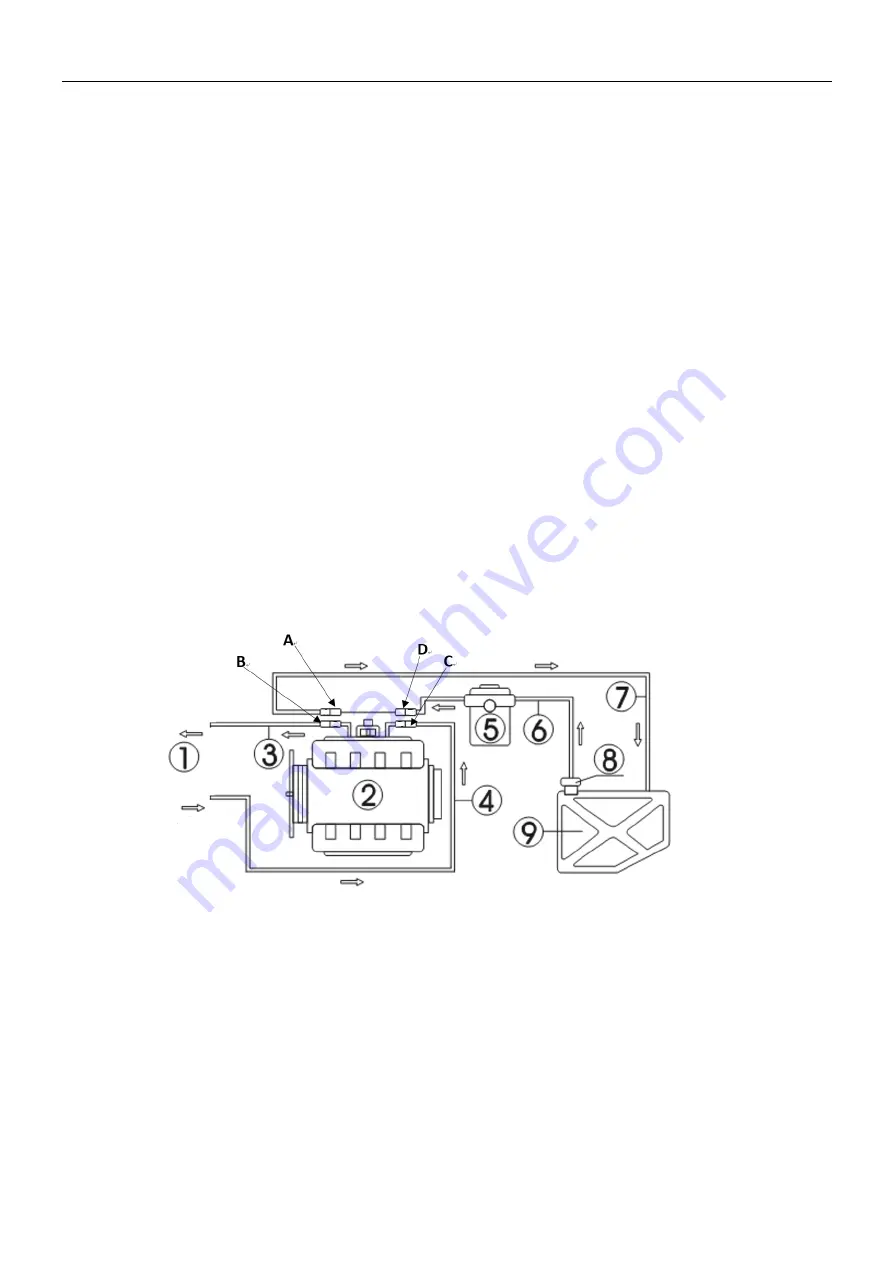

Connecting

There are two cases for the line connection: one is the connection with fuel-return hose and the other is the connection

without the fuel-return hose.

Connection with fuel-return hose:

1)

Disconnect the fuel supply hoses (C, D) and fuel return hoses (A, B) of the engine fuel system (when disconnecting

the fuel line connectors, cover them with towels). Choose proper connectors and connect them to the B end and C

end separately, and then connect the other ends to corresponding return hose and outlet hose of the device.

2)

Connect the two other disconnected ends (A, D) with a proper hose, or remove the fuel pump fuse, or disconnect the

power cable of engine fuel pump.

1- Injector Cleaner & Tester; 2-Engine; 3- Fuel-return hose from engine; 4- Fuel-inlet hose to engine; 5-Auto filter; 6-

Engine fuel supply hose; 7-Engine fuel return hose; 8-Fuel pump; 9-Fuel tank

Connection without fuel-return hose

1)

Disconnect the fuel supply hoses (E, F) of the engine fuel system (when disconnecting the fuel line connectors,

cover them with towels), and then choose a suitable connector, connect it to the E end and reconnect the fuel outlet

hose of the device. Hang the fuel return hose.

2)

Block the other end of the disconnected end (F) with a stopper (for fuel pump with fuel return function only) or

remove the fuse of fuel pump or disconnect the power cable of engine fuel pump.