10

POWERJET 260 PRO Injector Cleaner & Tester

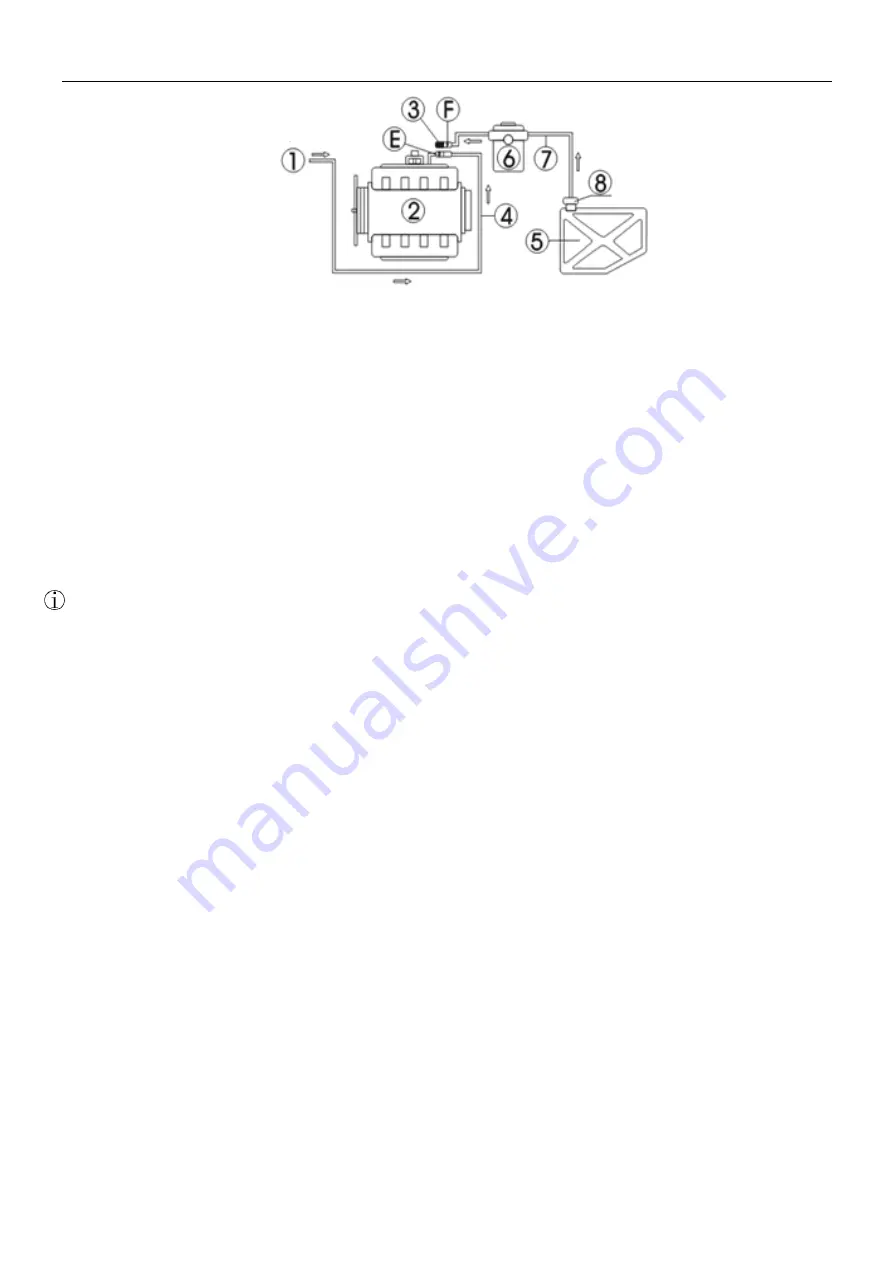

1- Injector Cleaner & Tester; 2-Engine; 3-Stopper; 4- Fuel-inlet hose to engine; 5-Fuel tank;

6-Fuel filter; 7- Engine fuel supply hose; 8-Fuel pump

;

Tidy up after cleaning

1)

After the on-vehicle cleaning is completed, turn off the ignition switch of the vehicle. Restitute the hose connection,

start the engine and accelerate properly to check if there is any fuel leakage at the connectors or in the hoses.

2)

Please clean the fuel tank and the lines of the device with test solution at the end of the on-vehicle cleaning, the

specific procedures are: drain the detergent left in the fuel tank first and dispose it according to its cleanliness. Add

a small amount of test solution into the fuel tank, connect the fuel outlet hose of the device to the fuel return port

and power on the device. Select “Leakage test” item and press RUN button to run the device for about 2

3 minutes.

After the running has stopped, drain the test solution from fuel tank and dispose the drained liquid according to

relevant regulations.

3)

Clean up the site and tidy up the washing machine for later use.

Note:

1)

When cleaning, care must be taken as the detergent is inflammable. Prepare at least one effective fire extinguisher.

2)

Be sure that all lines are well connected and there is no leakage before performing cleaning.

VI.

Transporting and Storing

6.1

Transporting

1)

Before being packed, the liquid inside the fuel tank should be drained completely to avoid overflowing as

transporting.

2)

Move only by hand or lift with soft belt.

3)

No package no lifting tools or long-distance transportation.

4)

To prevent the unit from shocking and knocking, make sure it is on the base seat and in the packing case during

transportation. Firstly pack the unit with the matter similar with plastic strip and add the filling material (such as foam

or sponge, etc.) between the unit and packing case to avoid scratching the surface when the unit shakes.

5)

Make sure that the maximum incline angel does not exceed 45℃. Do not place the unit up-side-down.

6.2

Storing

A.

Store only in dry area and keep away from water before the unit is unpacked.

B.

Store the machine in well-ventilated area and do not expose it to direct sun shine or rain.

6.3

Installation Environment

A.

Keep a distance of no less than 200mm between the unit and any wall or other substance. The unit should be put in

well-ventilated area. Make sure the temperature is within -10℃+40℃.

B.

The unit has been well grounded for safety operation. Please confirm that the power socket is also well grounded.