13

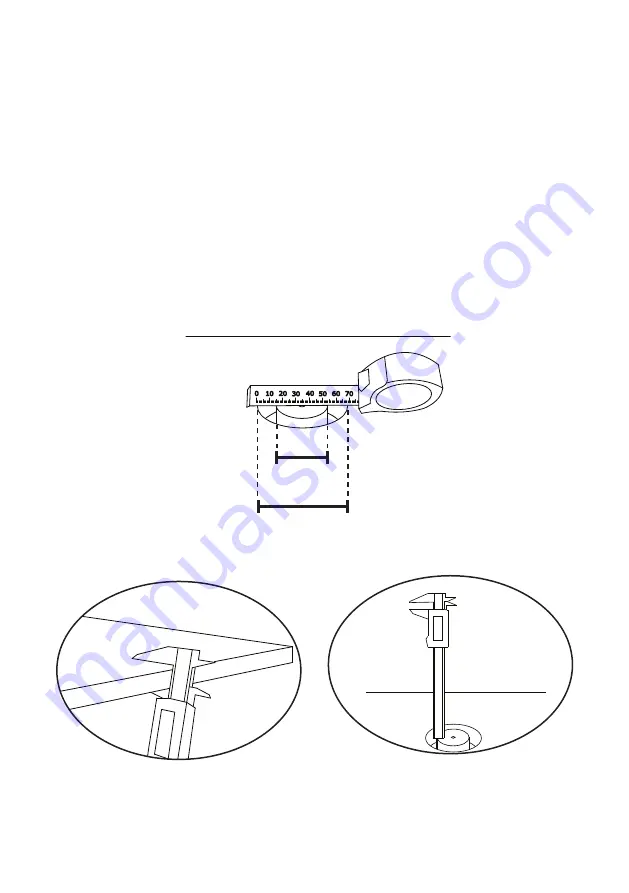

STEP VI - Checking the

groove

As the target fixture (see properties of

ready groove) has been processd to

the surface, remove the jig and ensure

that the thickness of the surface is

exactly 4 mm (±0.5) in the finished

groove. If necessary, do a another

round of processing. Also, check that

the inner diameter of the hole is 34mm

(±1 mm) and the outer diameter is 68

mm (±1 mm).

34 mm

(±1)

68 mm

(±1)

20

.0

0

mm

= 4 mm (±0.5)

-

16

.0

0

mm

For example, in case of 20 mm thick

table top the ready groove should be

16 mm deep in order to have 4 mm

thick surface in the finished groove (20

mm - 16 mm = 4 mm)

Summary of Contents for Jig

Page 1: ...PowerKiss Router Jig ...

Page 2: ...PowerKiss Router Jig User Guide Version 2 0 PowerKiss 2011 ...

Page 16: ......