4 - ENG

4 - ENG

OPERATING INSTRUCTIONS

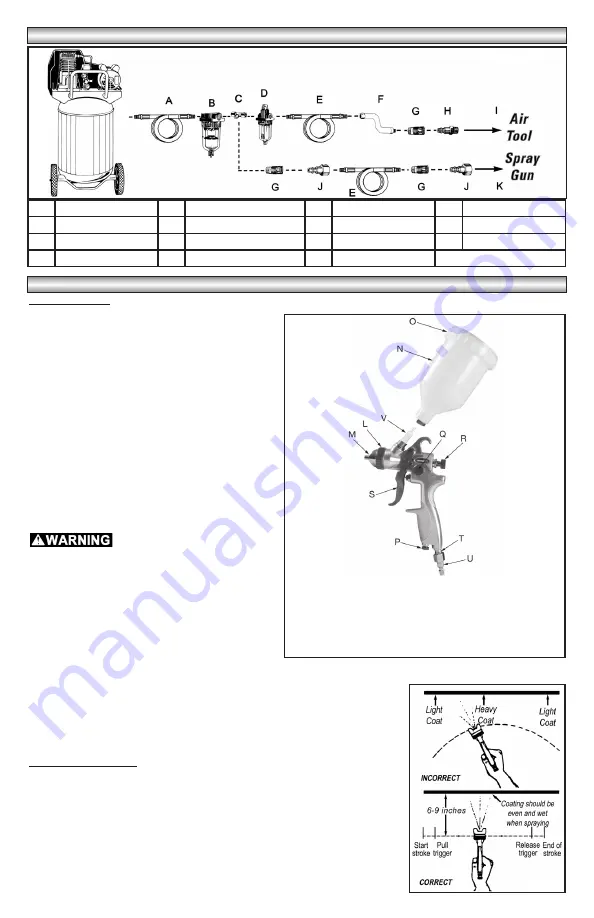

TYPICAL INSTALLATION

Before Spraying

1. As a standard practice, drain water from the air

Figure 2

L Air cap nut

R Fluid control

M Air cap

S Trigger

N Cup

T Air inlet port

O Cup cover

U Female connector

(put

Teflon® tape on the male threads)

P Air control

V Fluid filter

Q Pattern control

compressor tank and air lines prior to use each day

(reference your compressor operators manual for

detailed instructions).

NOTE: Failure to install

appropriate water/oil removal equipment may

result in damage to the spray gun or workpiece

(see

Figure 1).

2. Install a 1/4” NPT female connector (included in

accessory kit) onto the air inlet port of the tool.

(see Figure 2).

Note: Use Teflon® Tape on all

threaded connections.

3. Attach air supply line to 1/4 NPT female connector

plug.

4. Start the compressor and set the regulator to

30-50 PSI.

NOTE: Be sure there is sufficient

hose connected between the gun and air

supply to comfortably reach the work surface.

This spray gun is designed to

operate best at pressures between 30-50 PSI.

Never attempt to operate this spray gun at

pressures in excess of 50 PSI.

5. Mix material according to the manufacturer’s

instructions, adding thinner if needed. Mixture

should be smooth and easily pourable. Lumps or

foreign objects should be removed by straining

through a suitable paint filter or cheesecloth.

6. Insert a fluid filter into the fluid inlet (see Figure 2).

7. Attach the paint cup to the gun.

8. Remove the paint cup cover and fill the cup about 3/4 full with paint then

Figure 3

replace the cover.

NOTE: If using the spray gun for the first time, fill the

paint cup with thinner and spray into a grounded metal waste container

to flush the gun and cup of any impurities that may have accumulated

during assembly and shipping.

Spraying Instructions

1. Begin spraying. Hold the gun about 6 to 9 inches from the work surface

and while moving the gun from side to side, depress the trigger to begin

applying material. To avoid blobs, runs and lap marks, keep the gun in

motion at all times before, after and while the trigger is depressed (see

Figure 3). When spraying from the left to right, use the vertical pattern and

when spraying from the top to bottom, use the horizontal pattern (see Figure

4). Practice painting on a piece of scrap material or cardboard until the test

coating results are acceptable, making adjustments as follows:

Key

Description

Key

Description

Key

Description

Key

Description

A Air hose

D In-line Oiler

G Quick Coupler

J Female Connector

B In-line Filter

E Air Hose

H Male Connector

K Spray Gun

C Tee Fitting

F Whip Hose

I Air Tool

Figure 1