6 - ENG

6 - ENG

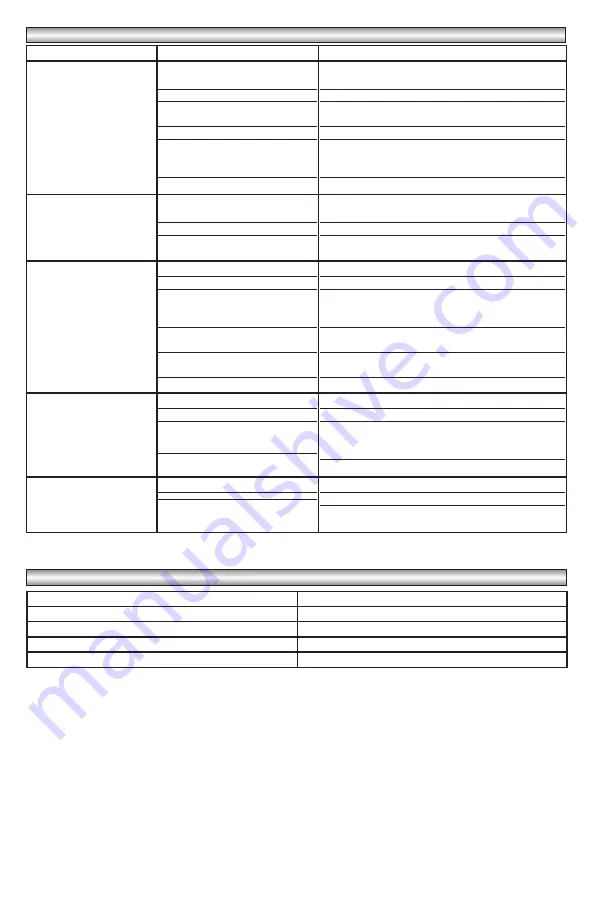

TROUBLESHOOTING GUIDE

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Gun does not spray

Air hose connection at compres-

sor loose

Paint cup loose

Fluid tube, fluid tip or air caps

loose, clogged or damaged

Air pressure too low

Material is too thick or needs

straining

Fluid control knob closed

Tighten and seal hose fittings with Teflon® tape if

leaks are found.

Tighten paint cup to gun.

Clean parts with solvent per instructions in the “user

maintenance” section.

Adjust regulated air pressure to 30-50 PSI.

Thin material according to manufacturer’s instruc-

tions and strain material using a paint strainer or

cheesecloth.

Adjust fluid control knob.

Material sags or runs

Material improperly thinned

Movement of gun is too slow

Gun held too close to work sur-

face

Thin material according to manufacturer’s instruc-

tions.

Move at a moderate pace, parallel to surface.

Keep the gun 6 to 9 inches from the work surface.

Spray pattern is distorted Fluid tip partly blocked

Clogged air nozzle

Material is too thick or needs

straining

Gun not held at right angle to

paint surface

Spray pattern adjustment knob

partially closed

Fluid control too heavy

Clean fluid tip and nozzle

Clean nozzle

Thin material according to manufacturer’s instruc-

tions and strain material using a paint strainer or

cheesecloth.

Hold gun parallel to the paint surface.

Turn spray pattern adjustment knob counterclock-

wise.

Adjust fluid control knob.

Spray pattern flutters

Paint cup loose

Packing dry, worn or loose

Material is too thick or needs

straining

Paint cup is empty

Tighten paint cup.

Lubricate and or tighten

Thin material according to manufacturer’s instruc-

tions and strain material using a paint strainer or

cheesecloth.

Fill paint cup.

Spray pattern is split

Fluid control too lean

Air pressure too high

Spray pattern adjustment knob

open too far

Adjust fluid control knob.

Adjust regulated air pressure to 30-50 PSI.

Turn spray pattern adjustment knob clockwise.

TOOL SPECIFICATIONS

Cup Capacity

20 Ounce

Nozzle Size

1.4 mm

Air Inlet

1/4” NPS (male)

Average SCFM Requirements

5-7 SCFM @ 40 PSI

Operating Pressure

Do not exceed 50 PSI