8- ENG LISH

Periodically clean the tool with compressed air.

Clean the magazine. Remove metal or wooden chips which

may have accumulated in the magazine. Periodically clean

magazine with compressed air.

STORAGE

WARNING

Keep out of reach of children and personnel unfamiliar

with tool operation.

Lock the storage area. Tools are

dangerous in the hands of personnel unfamiliar with the

tool.

When not in use, the tool should be disconnected and stored

in the storage case in a warm and dry place. When tool will

not be in use for an extended period, apply a thin coat of the

lubricant to the steel parts to avoid rust.

Do not store the tool in a cold weather environment.

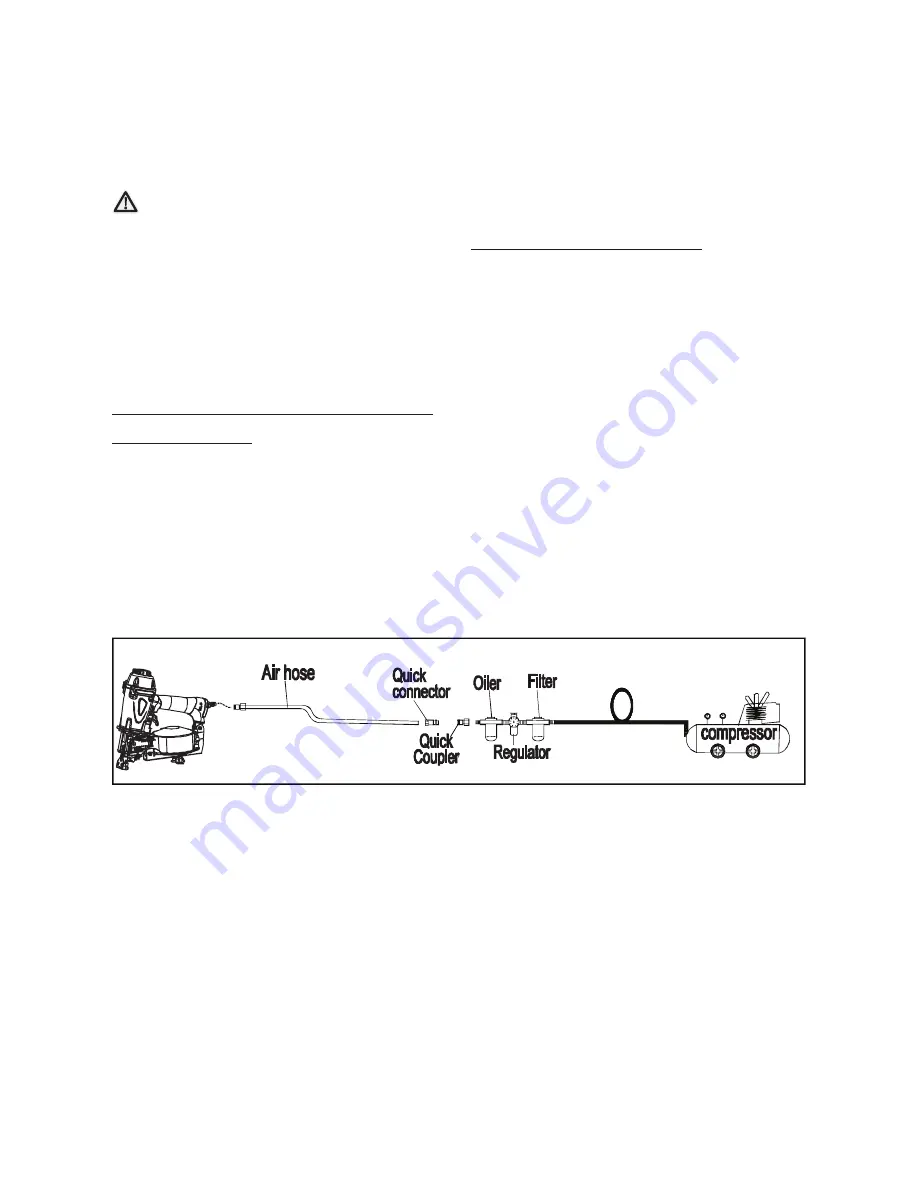

HOOKUP INSTRUCTIONS FOR TOOL

TO AIR SUPPLY

NOTE:

For better performance, install a 3/8 inch quick plug (1/4 inch

NPT threads) with an inside diameter of 0.315 inch (8mm)

on the nailer and a 3/8 inch quick coupler on the air hose.

1. With ON/OFF switch in OFF position, plug compressor

into electrical outlet.

2. Close pressure regulator by turning all the way to the

left. Turn compressor ON and let it pump all the way up

to automatic shut-off pressure.

3. Attach air hose to regulator outlet. Adjust pressure

regulator by turning to the right so that outlet pressure is

between 70PSI to 115PSI.

4. Load fasteners into nailer.

5. Point the nailer in a safe direction while attaching to air

hose.

6. Nailer is ready for use. You may need to adjust outlet

pressure to achieve proper fastener depth.

RECOMMENDED HOOKUP

MINIMUM COMPONENTS REQUIRED FOR

HOOKUP

Air compressor:

The air compressor must be able to

maintain a minimum of 70PSI when the nailer is being used.

An inadequate air supply can cause a loss of power and

inconsistent driving.

Pressure regulator:

A pressure regulator is required to

control the operating pressure of the nailer between 70PSI

and 115PSI .

Air supply hose: Always use air supply hoses with a

minimum working pressure rating equal to or greater

than the pressure from the power source, or 150PSI,

whichever is greater. Use 1/4 inch air hose for runs up to

50 feet (15.2 meters). Use 3/8 inch air hose for 50 feet

(15.2 meters), run or longer.