7 - ENG LISH

When using the tool in cold conditions the tool will cycle

slower than usual while driving the first nails. The cycle rate

will increase as the tool warms up. Keep tool warm to avoid

reduced cycle rate.

ADJUSTING THE NAILING DEPTH

WARNING

Disconnect the tool from the air source before making

adjustments. Such precautionary safety measures reduce

the risk or unintentional tool operation.

1. Disconnect tool from air supply.

2. Remove nails from the tool.

3. Adjust tool driving depth:

• To reduce the nail depth , turn the adjustment knob

counter clockwise (FIG 8).

• To drive the nail deeper, turn the adjustment knob

clockwise (FIG 9).

4. Reload nails as described in the “Loading Nails” section

of this manual.

5. Reconnect air supply.

FIG. 8

Too Deep

Flush

Turn the adjustment knob counter clockwise

Too Shallow

Turn the adjustment knob clockwise

FIG. 9

Flush

ADJUSTING THE EXHAUST

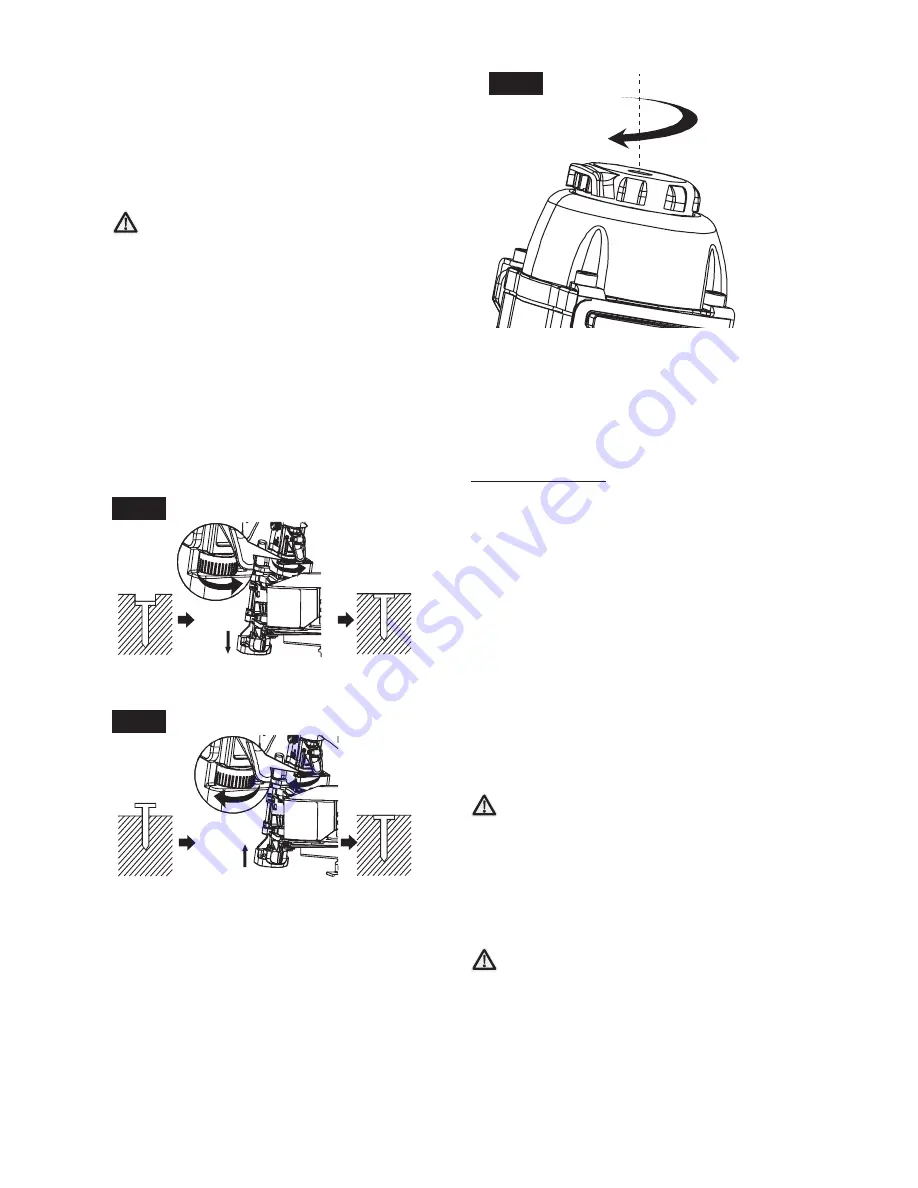

The direction of the exhaust vent can be changed by turning

the top cover (FIG 10).

FIG. 10

FIRING LOCK

The tool is equipped with a firing lock button beside the

trigger. Make sure it is in the position of the Lock Symbol

when tool is not in the use. Before using the tool, turn the

FIRING LOCK to the position of the Unlock Symbol.

MAINTENANCE

JAM CLEARING

Occasionally, a nailer may become jammed in the firing

mechanism of the tool, making the tool inoperable. To

remove a jammed nailer, follow the steps below:

1. Disconnect air hose.

2. Open the feeder cover and magazine cover.

3. Remove nails from the tool.

4. Remove jammed nail, using pliers or a screwdriver if

required.

5. Reconnect the tool to the air resource.

6. Reload the tool with nails.

7. Close the magazine cover. Close the feeder cover

securely.

CLEANING

WARNING

When cleaning a tool be careful not to disassembly any

portion of the tool since internal components may be

misplaced or safety components may be improperly

mounted.

Certain cleaning agents such as gasoline, carbon

tetrachloride, ammonia. etc. may damage plastic parts and

o-rings.

WARNING

Do not attempt to clean by inserting pointed objects

through openings.

Sharp edges may damage internal

components causing a serious hazard.

Ventilation openings, the work contact element, and the

trigger must be kept clean and free of foreign matter.