14

TABLE ROLLERS

Your planer is supplied with two table rollers (Fig.

14) which turn as the stock is fed into the

machine, thus reducing friction. It is not possible

to give exact dimensions on the proper height

setting of the table rollers because each type of

wood behaves differently. As a general rule,

however, when planing rough stock the table

rollers should be set at high position. When

planing smooth stock the rollers should be set at

low position.

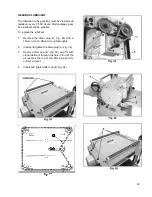

NOTE: When raising the roller higher above the

table, the range is from zero to 0.06" (Fig. 15).

The table rollers are factory set for average

planing and are parallel to the table surface. If

you desire to adjust the table rollers higher or

lower, proceed as follows:

1.

Disconnect machine from power source.

2.

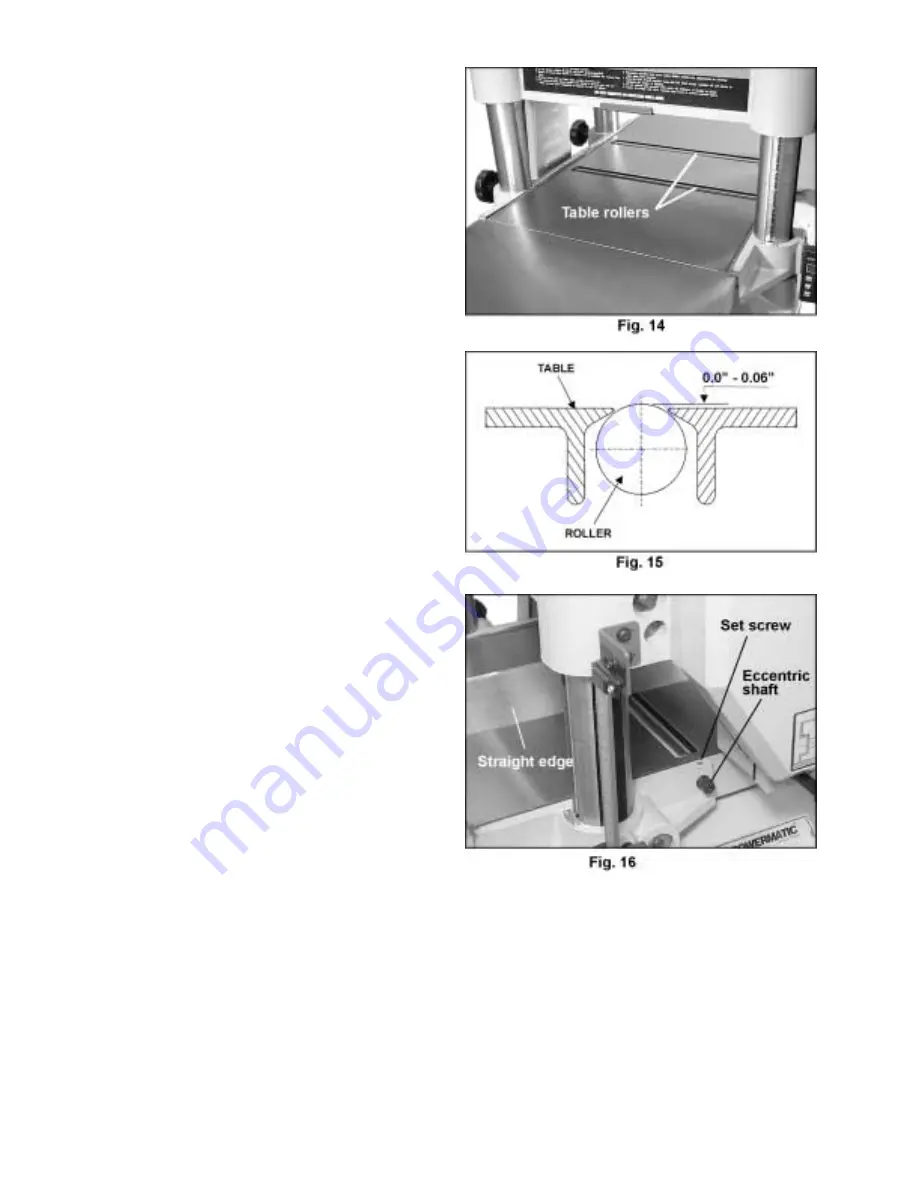

Lay a straight edge across both rollers.

3. On one side of the table, loosen the set

screws (Fig. 16) with a 3mm hex wrench,

and turn the eccentric shafts to raise or lower

the rollers.

4.

When proper height is achieved, tighten set

screws.

5.

Adjust the rollers from the opposite side of

the table in the same manner.

IMPORTANT: Be sure that the height of front and

rear rollers are the same. And the table rollers

must always be set parallel to the table.

Summary of Contents for 15S

Page 7: ...7 FEATURES 15S Planer Fig 2 ...

Page 33: ...33 Base Assembly 15S Planer ...

Page 35: ...35 Table Assembly 15S Planer ...

Page 37: ...37 Gearbox Assembly 15S Planer ...

Page 39: ...39 Cabinet Assembly 15S Planer ...

Page 42: ...42 Head Assembly 15S Planer ...

Page 43: ...43 ELECTRICAL SCHEMATIC 15S Planer Single phase 230 volt ...

Page 44: ...44 ...

Page 46: ...46 ...

Page 47: ...47 ...