21

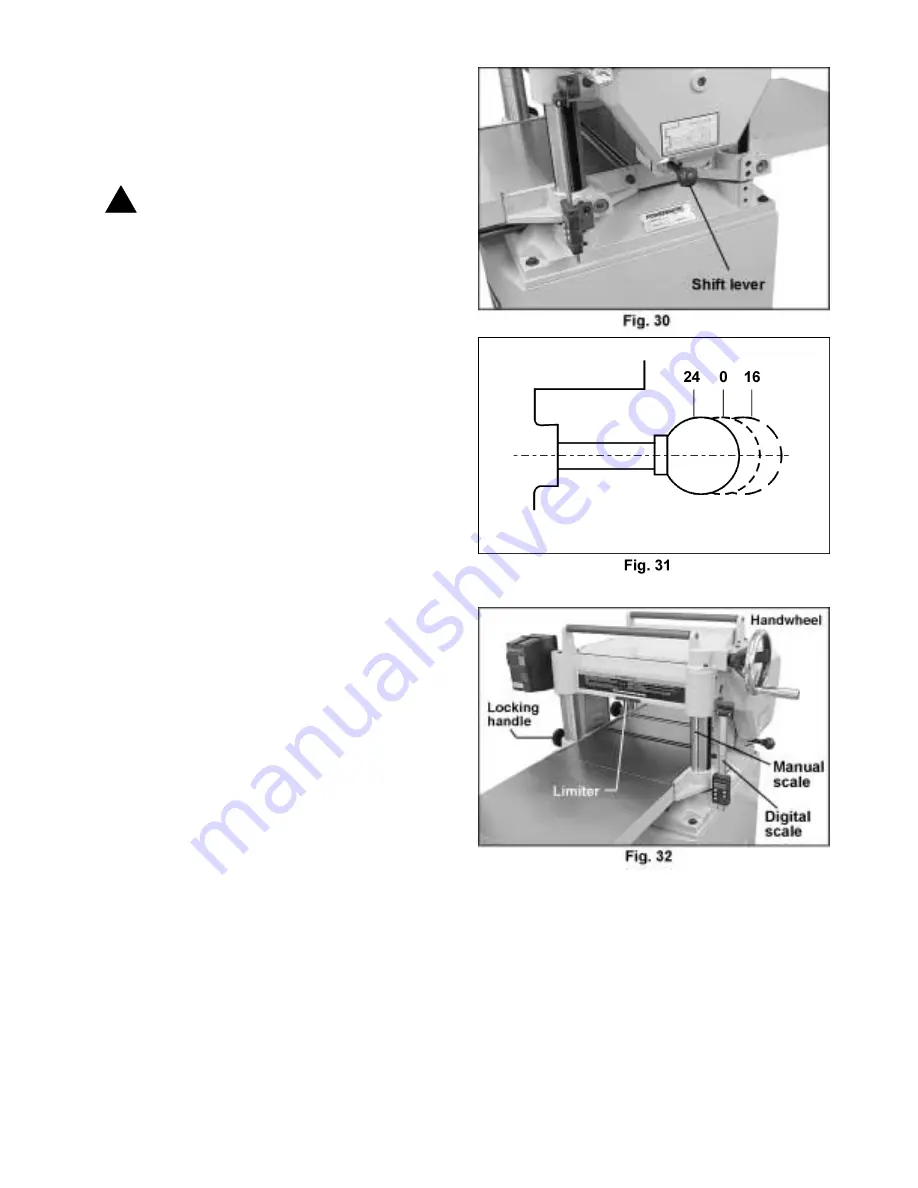

The gear box has two feed speeds. These are set

by pulling out or pushing in the shift lever (Fig.

30). Always change feed speed while the machine

is running. A label showing the lever positions is

affixed just above the lever. It is also shown in

Figure 31.

CAUTION: Do not attempt to change

feed speed while stock is passing

through the machine. Damage to the

gearbox may result.

STOCK RETURN ROLLERS

The two rollers on top the machine serve as a

convenient rest for stock. They save time and

motion for the operator as the stock is returned to

the infeed side.

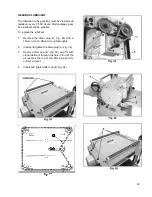

DEPTH OF CUT

The cutting depth scale is a combination

inch/metric scale (Fig. 32), with a cutting range

from 0 to 6" (152.4mm). A manual scale is

mounted directly to the front column. The model

15S planer also features a digital scale for easier,

more precise depth readings.

The distance of upward or downward movement

is controlled by the handwheel (Fig. 32). Before

moving the table up or down, loosen the locking

handles (Fig. 32). After obtaining proper table

position, tighten the locking handles.

Maximum depth of cut is 3/16". A limiter (Fig. 30)

on the front of the head casting limits the depth of

cut on full width planing under 1/8".

The digital scale should be calibrated before

operating the planer. Refer to page 24 for

instructions on calibration and function of the

digital scale.

!

Summary of Contents for 15S

Page 7: ...7 FEATURES 15S Planer Fig 2 ...

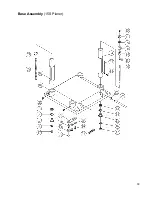

Page 33: ...33 Base Assembly 15S Planer ...

Page 35: ...35 Table Assembly 15S Planer ...

Page 37: ...37 Gearbox Assembly 15S Planer ...

Page 39: ...39 Cabinet Assembly 15S Planer ...

Page 42: ...42 Head Assembly 15S Planer ...

Page 43: ...43 ELECTRICAL SCHEMATIC 15S Planer Single phase 230 volt ...

Page 44: ...44 ...

Page 46: ...46 ...

Page 47: ...47 ...