22

MAINTENANCE

WARNING: Disconnect machine from

power source before performing any

maintenance.

Periodic or regular inspections are required to

ensure that the machine is in proper adjustment,

that all screws are tight, that belts are in good

condition and properly tensioned, that dust has not

accumulated in the electrical enclosures, and that

there are no worn or loose electrical connections.

Buildup of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is not only recommended but mandatory

for accurate planing.

Close-fitting parts, such as the cutterhead slot and

gibs, should be cleaned with a cloth or brush and

non-flammable solvent, and freed from clinging

foreign matter.

Remove resin and other accumulations from feed

rollers and table with a soft rag and non-flammable

solvent.

Periodically check all the chains for proper tension

and adjust accordingly if needed.

The table should be kept clean and free of rust.

Some users prefer a paste wax on exposed steel

and cast iron surfaces. The wax provides a layer of

protection as well as reducing friction between

lumber and the table, making cuts faster and

smoother. Avoid any wax that contains silicone or

other synthetic ingredients. These materials can

find their way into lumber and can make staining

and finishing difficult.

Another option is talcum powder applied with a

blackboard eraser rubbed in vigorously once a

week; this will fill casting pores and form a

moisture barrier. This method provides a table top

that is slick and allows rust rings to be easily wiped

from the surface. Important also is the fact that

talcum powder will not stain wood or mar finishes

as wax pickup does.

LUBRICATION

The bearings on the cutterhead are factory

lubricated and sealed for life – they require no

further lubrication.

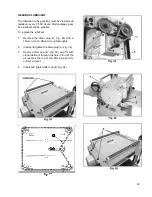

The item numbers on this chart are referenced with the illustrations below.

No. Position

Interval

Suitable Types of Lubricant

Fig. No.

1

Drive Chain

Inspect an lubricate monthly

Grease

34

2

Gear Box

When operated more than

2,500 hours

HD-100, Mobil Gear 627, Shell Omala 100,

ESSO Spartan EP-100

34

3

Return Rollers

Inspect frequently

SAE-30

35

4

Worm Gear

Inspect and lubricate monthly

Grease

36

5

Lead Screw

Inspect and lubricate monthly

Grease

36

6

Column

Inspect and lubricate weekly

Clean columns and apply SAE-30

36

7

Table Chain

Inspect monthly, lubricate

when needed

Grease, or good quality bicycle chain lubricant

37

8

Feed Rollers

Inspect and lubricate daily

before startup

SAE-30 38

Fig. 33

!

Summary of Contents for 15S

Page 7: ...7 FEATURES 15S Planer Fig 2 ...

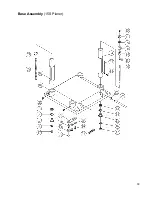

Page 33: ...33 Base Assembly 15S Planer ...

Page 35: ...35 Table Assembly 15S Planer ...

Page 37: ...37 Gearbox Assembly 15S Planer ...

Page 39: ...39 Cabinet Assembly 15S Planer ...

Page 42: ...42 Head Assembly 15S Planer ...

Page 43: ...43 ELECTRICAL SCHEMATIC 15S Planer Single phase 230 volt ...

Page 44: ...44 ...

Page 46: ...46 ...

Page 47: ...47 ...