26

12.0

Maintenance

Always disconnect power to

the machine before performing maintenance.

Failure to do this may result in serious

personal injury.

12.1

Cleaning

Note:

The following maintenance schedule

assumes the saw is being used every day.

Daily:

Wipe down the table surface and T‐slots with a

rust preventive.

Clean pitch and resin from the saw blade.

Weekly:

Table surface must be kept clean and free of

rust for best results. To facilitate this, apply a

coat of paste wax to the surface. Alternatively,

commercial spray protectants are available

from local hardware and tool stores. A good

protectant should provide rust protection for

the surface without staining workpieces.

Clean the motor housing with compressed air.

Wipe down the fence rails with a dry silicon

lubricant.

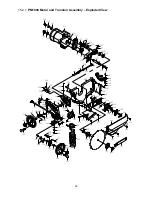

Periodic:

Keep the inside of the cabinet and trunnion

area clean.

Check for excessive play in the tilting and

raising mechanism and in the saw arbor and

adjust as required.

Check for belt tension and wear. Adjust or replace

belt as required.

12.2

Lubrication

Grease the tilting worm gear, raising worm gear,

and the trunnion areas with a good grade non‐

hardening grease.

Check all adjustments after lubricating.

12.3

Miscellaneous

Always be aware of the condition of your machine.

Routinely check the condition of the following items

and repair or replace as necessary:

Mounting bolts

Power switch

Saw blade

Blade guard assembly